Thread: Zach's G0704

Results 1 to 20 of 155

Hybrid View

-

02-10-2013, 07:24 PM #1

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

-

02-10-2013, 08:53 PM #2

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

I was/am under that impression. I've never used LinuxCNC before, only Mach, but LinuxCNC seems to have far more features. I figured some programming would be required for some of the more exotic features I plan on adding, like the ATC and glass scales. But the less I have to code the better... One of the things I like about LinuxCNC is the ladder. I've programmed a few PLC's before, and the ladders are pretty easy.

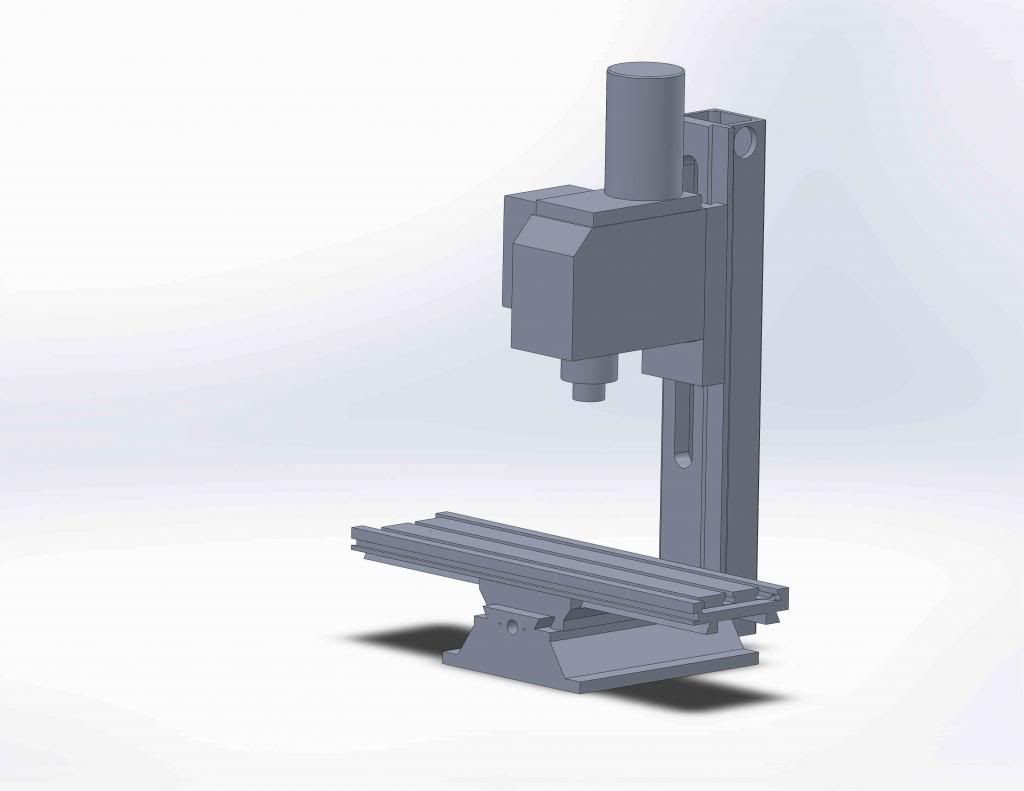

Finished up the initial Solidworks model. Everything is relatively accurate, +/- .010 on unimportant dimensions, +/- .003 on anything critical. My dovetail angles may be a little off, but I really don't think its going to mess anything up. I skimped on the head, for the time being. Once I get ready to upgrade the motor I'll put all the proper holes in it, for now its just there for aesthetics. Looks like I forgot the mounting slots on the base, I'll throw those in really quick. If anyone wants a copy of the drawing, PM me.

-

02-10-2013, 09:32 PM #3

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

The tool chain/changer/barcode logic was all done in hal/ladder.

[ame=http://www.youtube.com/watch?v=KplU8hkI0AQ&feature=share&list=UUHk52YjGT8 HryRYmJKSl-lg]Kearney and Trecker full tool change with spindle orient - YouTube[/ame]

The spindle control (gear shift, spindle lock, collet) was done in 'Comp' which is a C like language that allows you to write realtime hal componants. I could have done it in ladder but I am not strong in it - I could wrap my head around it programically.

sam

-

12-04-2015, 05:37 AM #4

Junior Member

Junior Member

- Join Date

- Nov 2015

- Posts

- 24

-

12-04-2015, 05:35 PM #5

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

Re: Zach's G0704

I'm running my servos closed loop in Linuxcnc. Basically, Linux measures the axis position, calculates the positioning error, and adjusts the speeds of the motors in real time to ensure the machine is exactly where it needs to be. Any modern vmc will have closed loop servos. Typically, encoders are mounted on the servo motors are used. For the dmm servos, however, there was no encoder out signal. Therefore I had to add either rotary or linear encoders. I chose linear, since they would also compensate for ballscrew error. This is working well for x and y, but not so well for the z. I'll get to that in a later post.

If you run stepper motors or servos in step direction mode you won't need to add encoders, but you also won't know where the machine actually is or if something goes wrong.

Why Solidworks? Because I'm designing a mechanical device in the 21st century. I model even my simplest projects, even woodworking and welding. It allows the designer to check clearance and fit, get accurate material requirements, estimate weight, and, of course, make pretty pictures.

-Zach

Sent from my SM-G920V using Tapatalk

-

12-04-2015, 06:06 PM #6

Member

Member

- Join Date

- Sep 2008

- Posts

- 229

Similar Threads

-

DRO for G0704

By UMR in forum Benchtop MachinesReplies: 4Last Post: 07-06-2016, 04:04 AM -

No Joy with my New G0704

By DogWood in forum Benchtop MachinesReplies: 5Last Post: 07-05-2016, 05:49 PM -

Zach's Homebrew CNC Mill

By Zach_G in forum Vertical Mill, Lathe Project LogReplies: 76Last Post: 06-27-2015, 04:28 AM -

G0704... Yes Another One ;)

By ww_kayak in forum Benchtop MachinesReplies: 24Last Post: 05-27-2013, 03:47 PM -

G0704 or a X-3

By USN in forum Benchtop MachinesReplies: 8Last Post: 05-30-2011, 08:24 AM

Reply With Quote

Reply With Quote