Ok... Back to my old build. What was the last pic? Oh yeah. Lifting the mill onto my bench.

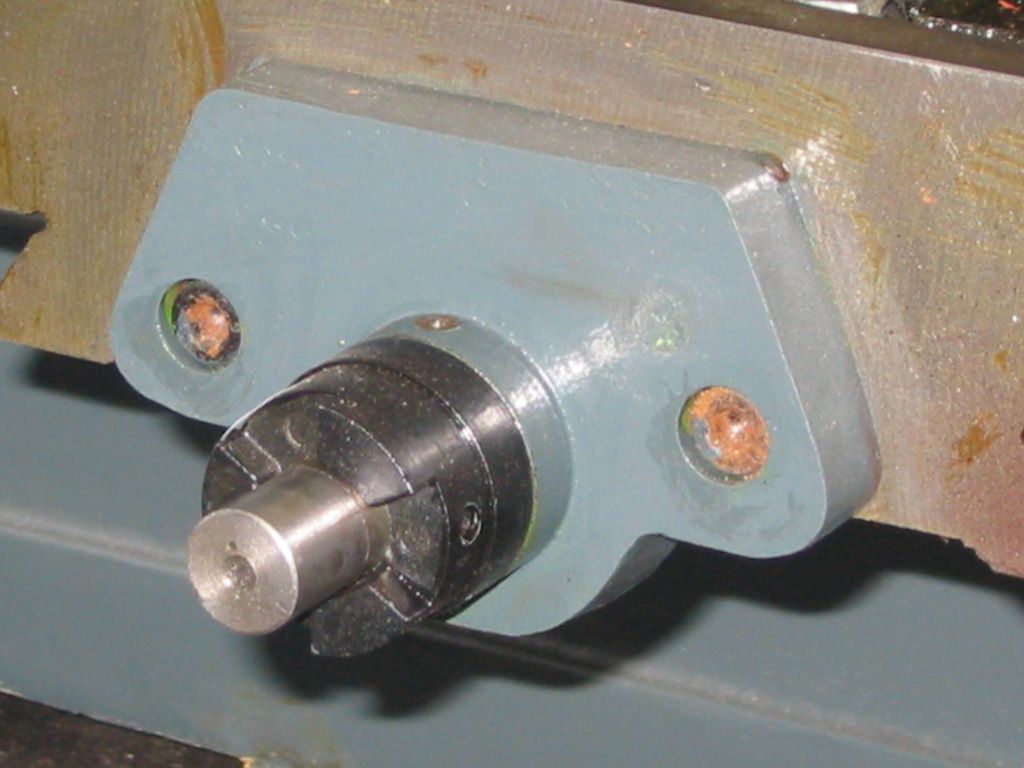

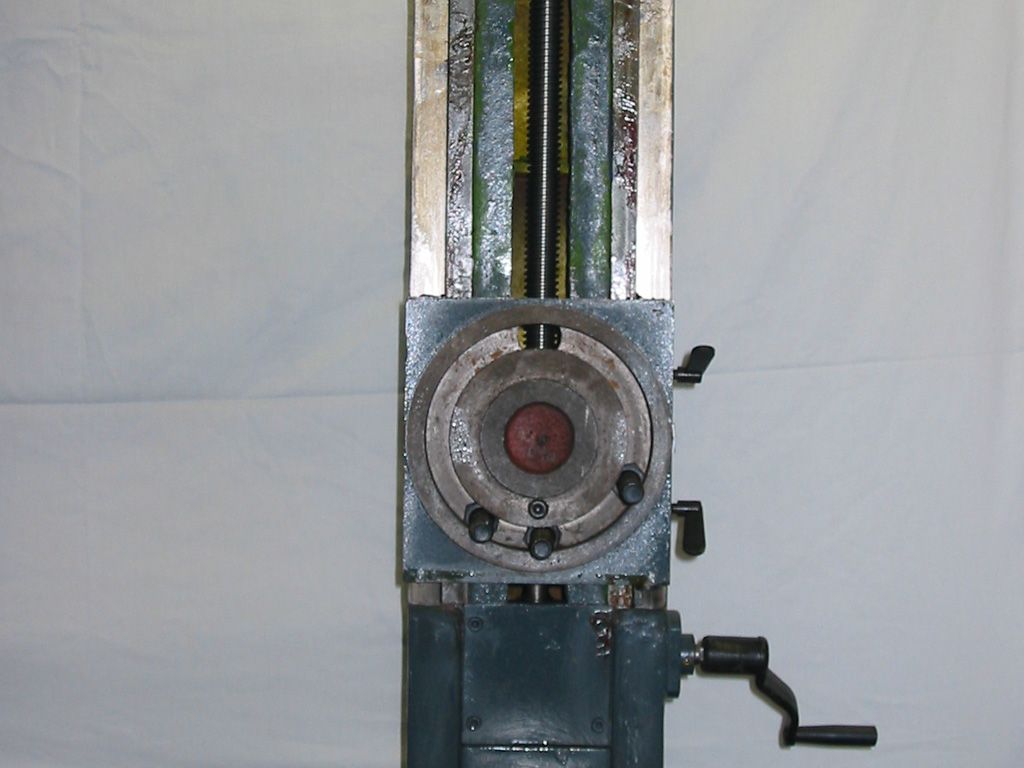

After the lift I took many pics of the mill so I could go back and see how it was assembled before I took the next step which was a complete tear down. For me it was a hard thing to do. A brand new mill that was good to go to do some milling. Kinda like buying a new car and ripping it apart like some shows on TV do. Well? Im not a TV show with massive amounts of money so to basically break a machine is the last thing I wanted to do. It was necessary. ALL the drive screws and nuts, all the crank handles and mounts and the quill feed parts. All stuff I paid for that needed to be removed.

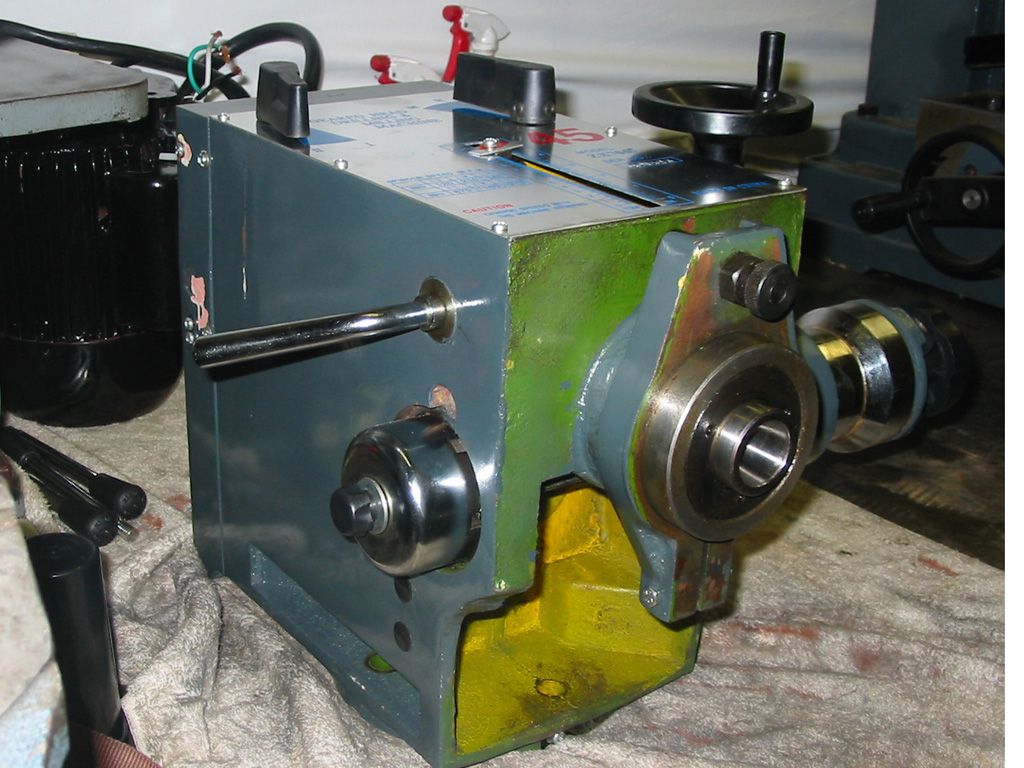

Comes down to the table, saddle, bottom cast frame and the vertical cast column with the Z axis and gear head. The geared head will be gutted and I will use a belt drive with an A/C or D/C spindle motor. I have a 30 taper spindle I got from Aaron. But?? I am thinking I might not use it. I think I want to make a spindle for the mill and use some of the tooling I have. Too much tooling..

I have seen some of the vids for the tormach tooling system and love the way it works. And its not overly pricey. But there are some properties I dont like about it. Mainly that its still a draw bar system that works though the R8 taper.

The head on my machine will be a fixed quill, belt driven spindle and not ATC capable. FYI? Look at some of the TTS vids. They will make you want that system. I do. But it is not part of my plan.

Tear down....

All the red grease.

Rust.

Results 1 to 20 of 64

Threaded View

-

04-07-2013, 06:05 AM #11(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

Similar Threads

-

Enco vs. Grizzly square column mill

By kc6uvm in forum Benchtop MachinesReplies: 15Last Post: 10-11-2012, 07:16 PM -

Enco RF-45 clone CNC convertion.

By LUCKY13 in forum Vertical Mill, Lathe Project LogReplies: 18Last Post: 04-26-2012, 07:54 PM -

enco 45 square column mill

By atomize in forum Benchtop MachinesReplies: 11Last Post: 10-19-2008, 09:46 AM -

Enco Square column onsale w/free shipping

By JRouche in forum Benchtop MachinesReplies: 3Last Post: 05-07-2007, 06:44 AM -

HARBOR FREIGHT small round column mill to a square column conversion.

By motomitch1 in forum Vertical Mill, Lathe Project LogReplies: 25Last Post: 12-01-2005, 05:24 PM

Reply With Quote

Reply With Quote