Those Pittman motors are way more powerful than one would expect, they would run the mill fine. Its a shame we lost Aaron as the owner of IH, IMHO the people lost a lot of what Aaron was trying to do for them when IH was sold. Its my understanding the company has again been sold, hopefully they will bring the company back to a level more in line with what it was when Aaron was running it.

I have this exact mill, mine was built in 2001 (same color also). I have been pleased with mine all though a little trouble with the Z axis. The motor on mine has held up great, in fact I feel like it may be a little better than most Asian motors that come with many of the mills these days. Both power and durability have been very good with it. On the Z axis the dovetails have spread a bit at the bottom of the travel ( casting seasoning maybe?). Its not bad, but something has moved in the casting to cause it and it gets tight at the bottom of the travel.

One problem I did have was every bearing in the head that was above the oil line died with in hours of breaking in. They had drawn moisture and rusted. Mine set in storage for many years also so this may have been the reason.

I think the Y axis nut mount will be different than the mount supplied by Aaron, and maybe even the X axis. The Z axis mod Aaron outlined to fix slop in the will need to be dune the same as the IH mill (maybe some small differences).

Also every gib in the machine may really need help. They looked like you took a grinder to them on mine, but after making them flat/fit the machine worked so much better. Movement, accuracy and slop where all improved a great deal and the machine has shown no signs of wear in a few years of use. No lapping/scraping on the dovetails, just the work done on the gibs.

Over all I feel these are good castings/machines to start with. Maybe no better than others, but certainly no worse. BTW be careful when moving the head around, they use filler to smooth the sides of the head before painting. It will chip and come out in chucks if you let something dig into it. The paint has held up very good on mine (where I didn't crack the filler) so if you can keep from chipping when doing the CNC mods it will be worth being careful with the painted surfaces.

IDK if your going to go with ball screws, if not the factory nuts and end mounts are possibly the worst part of this machine. New nuts and end bearings would fix this, but with Aarons kit you will at least have the end bearings covered. The factory nuts do have backlash adjustment, but it leaves it to stiff for hand cranks, but may work ok with the servos. Ball screws would be best.

Jess

Results 1 to 20 of 64

Hybrid View

-

04-05-2013, 08:59 AM #1

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 839

GOD Bless, and prayers for all.

-

04-05-2013, 10:29 PM #2

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 0

Hey Jess, you don't happen to still have your factory leadscrews and nuts do you? You aren't kidding about the factory nuts being bad, my x-axis is completely gone, and the y isn't feeling good anymore either.

JR is going to see if he still has his, but I wouldn't mind ending up with 2 sets if it comes to that. I'm still not convinced I want to CNC my mill...

BTW, I would have PMed this message, but your inbox is full Chasing tenths is hard...

Chasing tenths is hard...

-

04-06-2013, 05:40 AM #3

Hey Jess. I don't normally "quote" an entire post but I couldn't find a place to cut your reply. I agree 100%

I bought one of Aaron's first RF-45 kits (full three axis, servo, ballscrew encoder unit). I talked with him for hours on end. We have similar backgrounds. I enjoyed our convos till he sold the shop and went to work for TCI. Did the BIG move. Yup, Moss TCI Haha. Never woulda known it. Dude was down to Earth. JR(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

07-05-2013, 08:19 AM #4

Photobucket ERRR!

JR

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

JR

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

07-05-2013, 10:02 AM #5

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 980

-

07-03-2013, 06:23 AM #6

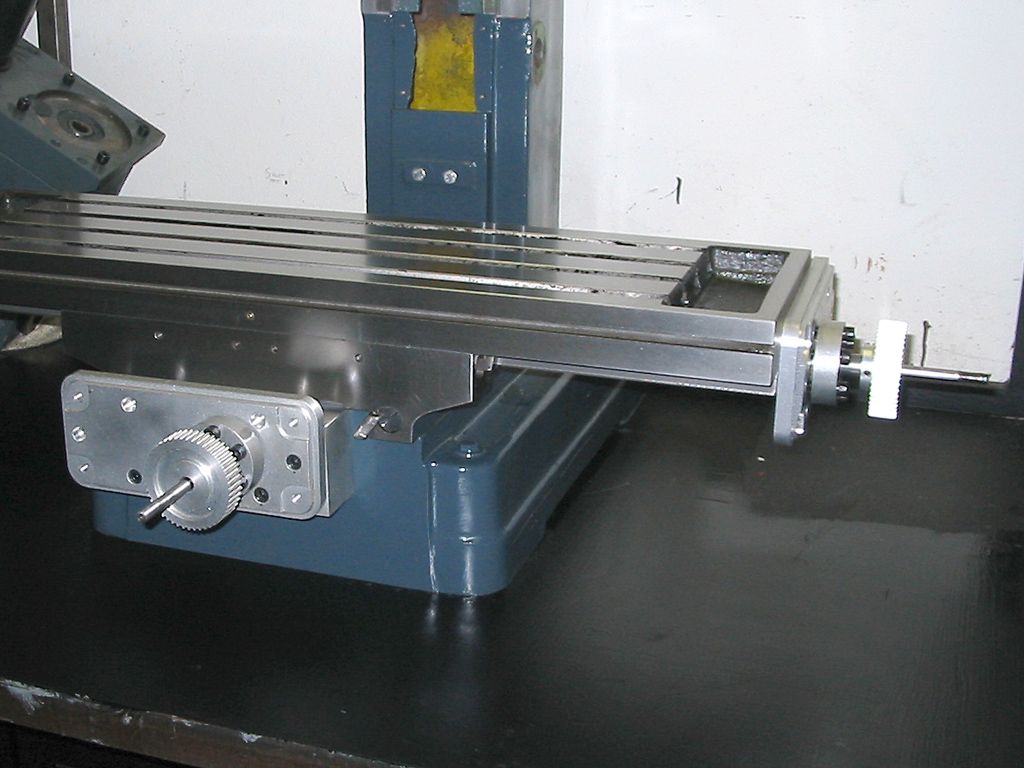

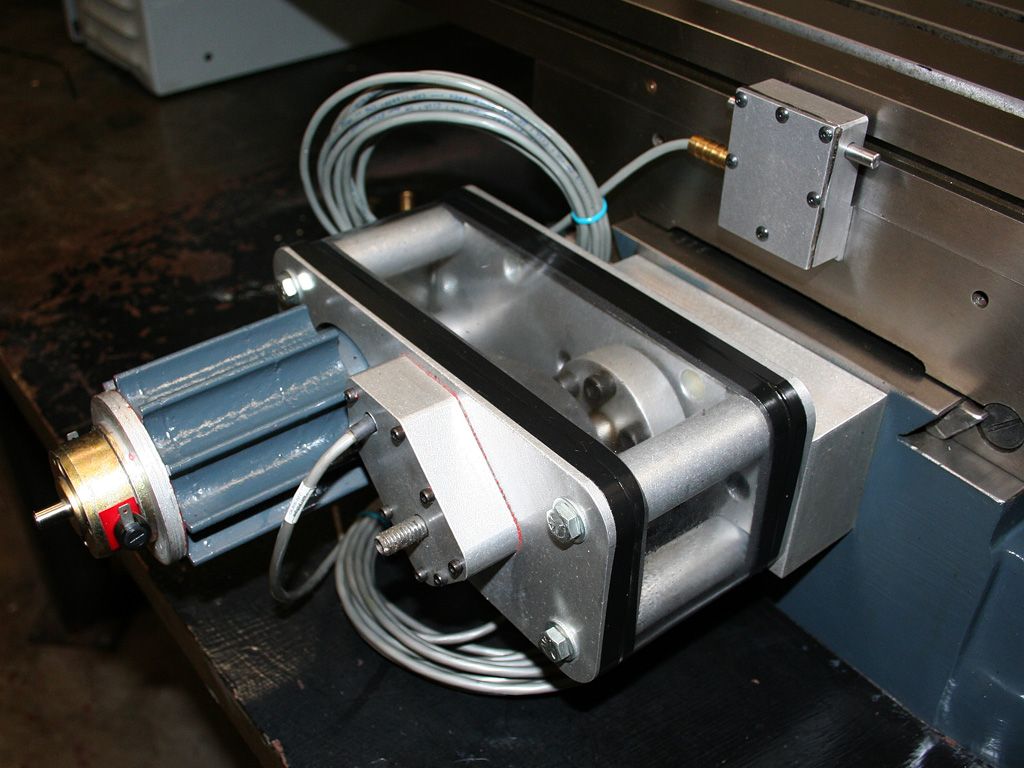

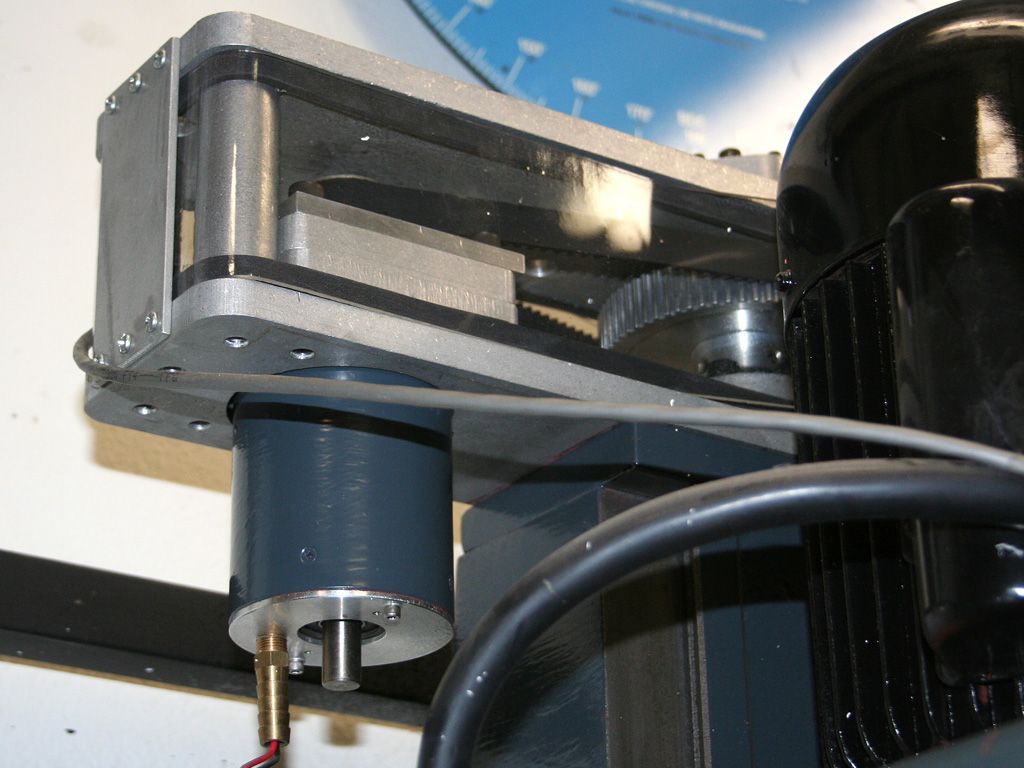

More pics. The table on after the ball screw nuts and screws were mounted. One part I didnt talk about was the ball nuts were wrapped in heat shrink tubing to help keep "junk" out of them. I wish I would have made provisions for oiling of the nuts/screws. I have a feeling the entire assembly will be apart again to plumb some lines to them. Live and learn, I hope

Table back on.

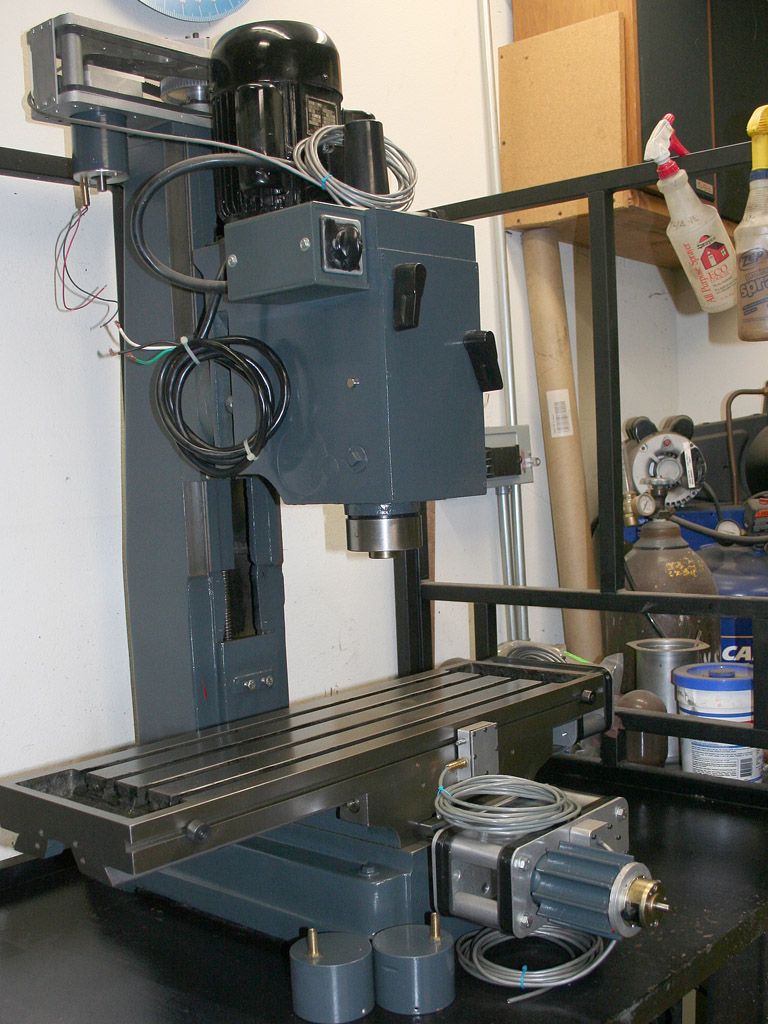

So YES! handlewanker This is the final look of the machine as of this month. Finally right LOL I have done some work that is current and will sort out those pics. It was a chore to find all the old pics and figure out what to write. Its kinda a drag to post old pics and try and think of something to say. But now that it is current work I can just lay into it and bore the hell out of you guys with my tendancey to run on with talk

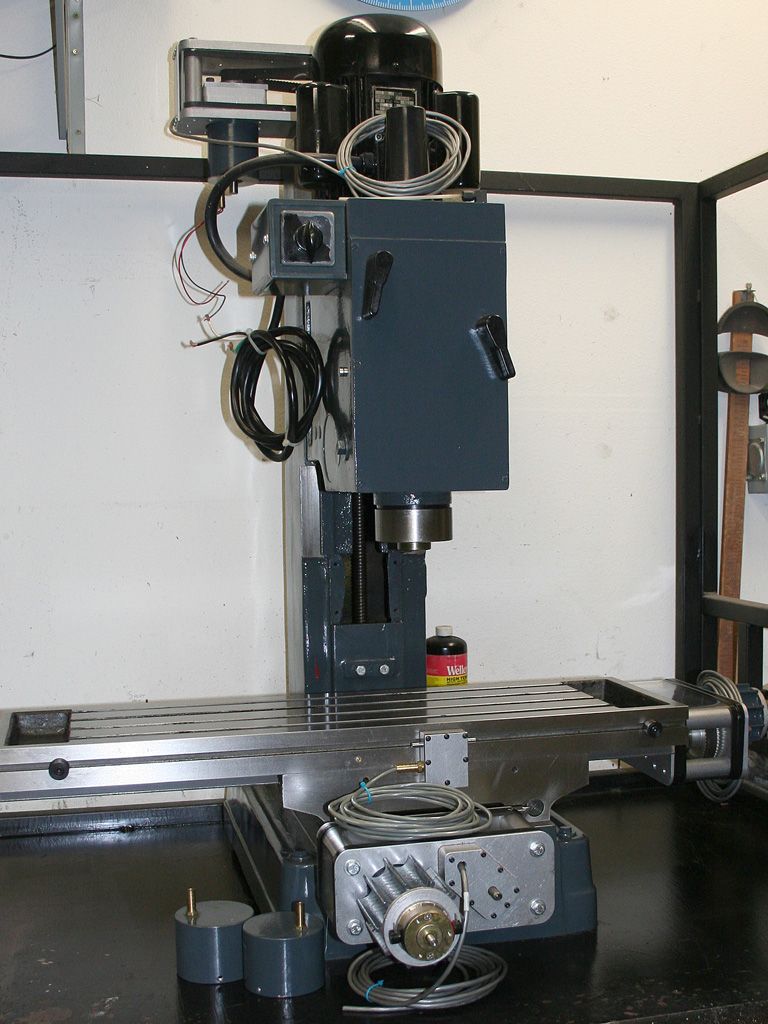

As she sits today.. More to follow but prolly not any faster due to the snails pace at which I travel with my projects. I will try to keep it worth reading though. Really sorry for the old stuff I posted but to make it a story I thought I should show how it evolved to the point where it is now. It had a beginning and the story should start at the beginning. Bear with me folks

Sitting after six years of neglect. She will get some life giving electrical energy within the year I hope. Ok, thats a lil far fetched optimism JR

JR

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

Similar Threads

-

Enco vs. Grizzly square column mill

By kc6uvm in forum Benchtop MachinesReplies: 15Last Post: 10-11-2012, 07:16 PM -

Enco RF-45 clone CNC convertion.

By LUCKY13 in forum Vertical Mill, Lathe Project LogReplies: 18Last Post: 04-26-2012, 07:54 PM -

enco 45 square column mill

By atomize in forum Benchtop MachinesReplies: 11Last Post: 10-19-2008, 09:46 AM -

Enco Square column onsale w/free shipping

By JRouche in forum Benchtop MachinesReplies: 3Last Post: 05-07-2007, 06:44 AM -

HARBOR FREIGHT small round column mill to a square column conversion.

By motomitch1 in forum Vertical Mill, Lathe Project LogReplies: 25Last Post: 12-01-2005, 05:24 PM

Reply With Quote

Reply With Quote