I had to take a second look, makes me wonder if it is pullout.

I'm impressed with it. Size wise it looks like it could really give many of the small machines on the market a run for their money. I'd like to see him produce a companion machine that is maybe twice maybe 3 times as large.Won't be good advertising if the resulting finish is uneven or otherwise crummy, ya know?

It's a dandy little machine that you've built here.

Since there are no good, purpose designed small CNC slant bed lathes on the market, I'd like to see him do on of comparable size to this mill.Mayhaps we could speak about doing a design and casting set for a medium sized slant bed CNC lathe.

Conversion lathes leave a lot to be desired. A seven or eight inch lathe with 16 to 20 inches between centers would be most interesting. Actually now that I'm thinking about it I'm not even sure that much distance between centers makes sense. There are many applications where huge center distances would not mean much on a CNC lathe. Note though that I'm talking about a purpose built small CNC lathe.CNC Lathes are pretty simple, iron wise, and hardly anyone sells anything more useful than a 7x10 or maybe a 9x13.

That is a rather large lathe that frankly already has offerings that one can choose from. I'd rather see a unique product enter the market.I'm thinking something that can honestly swing 10" diameter with 30"-36" between centers.

I'm certain others would like to provide input as there are few solidly designed small CNC lathes on the market. CNC lathes just don't seem to have the appeal of a mill. I would caution against going too big for the first machine, I'd rather see it as a counter part to this mill.PM me if you'd like to discuss further. I'd be willing to assist if it would help bring this project to fruition.

Results 241 to 260 of 3662

Hybrid View

-

04-11-2013, 06:44 AM #1

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 3920

-

04-11-2013, 08:17 AM #2

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi, wizard. I have the same thinking that the CNC lathe should be a counter part to the mill series. The scale should be fitful to the mill size. And yes the larger ones are provided on market now. I also plan to build 2X,3X one by one to market if can get initial success from this one. So I think if the current mill business can go smooth I will do that. The slant bed CNC lathe structure is the best choice. I will let you guys know too for some ideas and discussions. :cheers:

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-11-2013, 06:56 AM #3

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Aww gee Skyfire, you've made the machine all dirty and covered in chips.....does this mean this machine will be sold as a demo model, shop soiled etc, priced accordingly....pant, pant....?

BTW, I would not imagine there was enough torque developed to pull the cutter down out of the ER collet, but as the cutter has a very fast spiral it could happen.

Under those conditions, where a cutter was pulled out of the collet under a load, would an opposite handed spiral, IE, anticlockwise instead of clockwise looking end on, (spindle running in reverse), force the cutter back into the collet.......it would mean that you could not drill into the metal or ramp in as it is an end mill designed for milling on the side, and the end face would have a negative rake anyway, but the advantage of not digging deeper into the job than planned would outweigh this lack of drilling ability.

I have a set of Metric ER 32 collets and also a number of Imperial endmills and slot drills, and when the shank size is 3/4", it means you have to go to a 20mm collet and squeeze it down to 19.05mm, which it is designed to do, but as it's rather extreme, I invested in a set of imperial collets to offset the problem.

Ian.

-

04-11-2013, 08:10 AM #4

If it's pull out, this is probably the cause of it.

You'd be surprised how much thrust a high helix endmill will exert. I've had bigger endmills pull out of R8 and TG100 collets before too.

Wizard, if he wants to build a smaller machine than the one I suggested, I say go for it. I'd probably have a use for it too, but I could really use a machine of the size I noted before.

Got any links to what's available already? I've been looking for a while now, and coming up pretty much empty. Nothing but quasi-CNC flat bed conversions from China and India.

I could use a slant bed big enough to get rifle barrels inside, but I don't have $60k to drop on a used machine that's 20 yrs old.Ryan Shanks - Logic Industries LLC

http://www.logic-industries.com

-

04-11-2013, 08:31 AM #5

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi my friend, I think I have to sacrifice some of this prototype appearance to prove it's a real deal

.. I think maybe it will be sold as the demo one with some discount... But if I could I prefer more to keep it as a record,,haha..

.. I think maybe it will be sold as the demo one with some discount... But if I could I prefer more to keep it as a record,,haha..

The tool out of collet issue is just the spanner issue.. So I couldn't fasten the collet tight enough especially for heavy cutting test. I will do it again today and it will not be a problem

I agree that really need many size collets to hold tools properly. Or it could happen the situation like this. I think MAX 1mm adaptale for a collet is some extream range.www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-11-2013, 10:07 AM #6

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 3447

I'd keep it, use it as your customers would, and use it hard. See what breaks, or can be improved, and incorporate those changes into the second machine.

-

04-11-2013, 08:02 AM #7

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi, The reason is tooling pull out of collet indeed. When I did this test last night, I found I can't find my 28mm spanner to fasten the collet! I have to hold the pulley by hand and obviously I'm not Popeye

So the tool has been pulled out under the heavy cutting test. It will not be a trouble today. I just got the fitful spanner.

So the tool has been pulled out under the heavy cutting test. It will not be a trouble today. I just got the fitful spanner.

Yes, as you suggested, I will take the video again today. should be much better now.

I do have thought about the CNC lathe to bring series of CNC machines to market if I can have initial win for the current CNC mill. Sure, I will contact you for discuss when I be able to start the lathe project! Thank you very much my friend.:cheers:www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-11-2013, 12:12 PM #8

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Whew, glad the loose tool issue was just the lack of a spanner.

I hope the 4th axis design gets off the drawing board before the lathe is thought about.

I couldn't think of any current design upgrade, apart from coolant, one shot lube and/or built in ratio change....maybe a QCT or power drawbar, that would make the machine more versatile....if you increase the X, Y or Z range you just start getting out of proportion....... this is something like pumping a midget full of steroids in the hope that he'll exceed the 4 minute mile record....LOL.

If the machine build went to ICNC-2 or 3, and the parameters were scaled up, all you'd achieve is another big mill and a higher cost pro rata, eventually you'd have to decide if you really want to have another knee mill as big as a Bridgeport.....LOL.

On the topic of a CNC lathe, it would be cool to have a midi lathe that really barked......something that would hold a 30mm bar of steel through the headstock and have a gang tool slide for simplicity......short bed and no tailstock.......I'm not all that wowed by a slant bed design.

In my opinion, the moment you have an enclosure and coolant gushing at a rate of knots, it becomes something like a commercial scene where you just become an operator that pushes the green button when the red light flashes.....or feed bars as the hungry beast gnaws away to itself, but if the need is for a commercial machine, then the list is already long and as varied as the price range.

One of the most sort after aspects of lathe design, be it manual or CNC, is the ability to cut any thread pitch electronically.

If the design also incorporated a milling head on the tool slide, then that makes it pretty versatile.

Ian.

-

04-11-2013, 06:40 PM #9

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi,

Yes. just the spanner issue. I got a new one today and fastened the tool well today and did the heavy cutting tests again. Nothing like pulling out collet happened again

I will still focus on the mill and it's optional parts including the 4th axis in near future. I think I probably can start a lathe project when eveything is on the way for this mill series. I think it will be somthing like you said, and hope to intigrate many good features..

I think for now I have finished the whole body of this ICNC-1, and I will provide some accessory options like coolants(this is easy thing), different ratio gears&belts and electric spindle system. Considering the shipping size issue, The enclosure maybe too big for most users. and It's easy to build as what you want.. This can be a DIY thing.. I can provide a full enclosure type too, but I think it will be an optional part too. The basic type machine should be most performance cost for most users now. And other things are just depend on different needs.

www.skyfirecnc.com

The basic type machine should be most performance cost for most users now. And other things are just depend on different needs.

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-11-2013, 04:49 PM #10

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

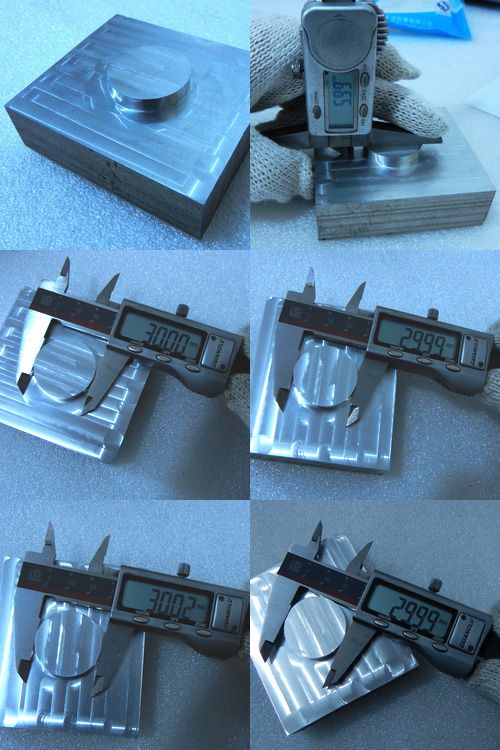

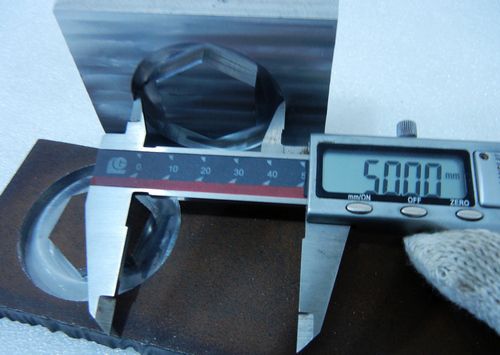

Here is the accuracy detection passage video. All errors are limited to 0.02mm and typically 0.01mm.

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-11-2013, 08:41 PM #11

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi guys. I think I've fnish the total tests today. Here are my test results today including:

1. aluminum cuttings

2. steel cuttings

3. long time cutting test and overload destructive cutting test

4. programed cuttings both on aluminum&steel material, real cutting accuracy measurement

------------------------------------------------------------------------

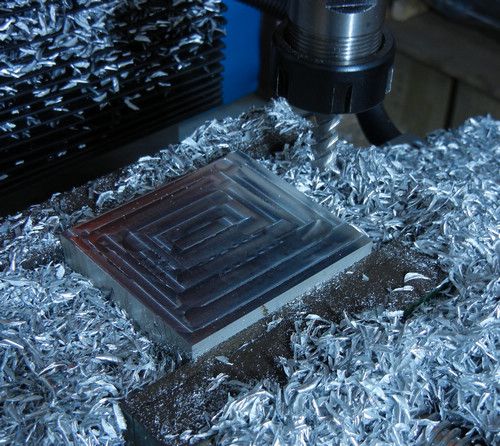

1. aluminum cuttings

I repeated the mass material removing test under JOG mode as yesterday and fastened the collet tightly with a new spanner. No tool loose happened again. The cutting video I will post soon tomorrow.

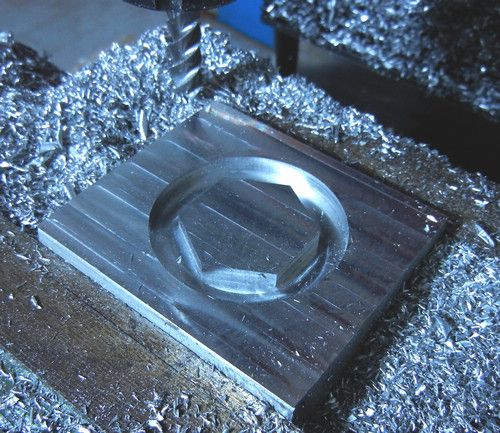

2. steel cuttings

I tested this with a 45# steel board and proved the machine can handle steel cut no problem. Just don't run upon the spindle power capacity and don't destroy the tool

Here are several cuting pictures under jod mode.

3. long time cutting test and overload destructive cutting test

I run the machine over 10 hours today and no any abnormal things happend. The transformer is not even worm. all drivers keep low temperature under the fan cooling. spindle and spindle motor din't overheat. The stepper motors are some hot but within the normal stepper motor temperature range.

I run the spindle to extream conditions of jamming tools under a very hard condition as I replied to diyengineer. Even the main fuse blew the machine is still no further damage and did the following program cutting tests and passed the accuracy measurement.

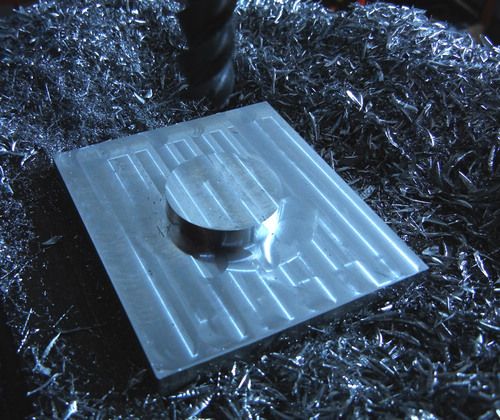

4. programed cuttings both on aluminum&steel material

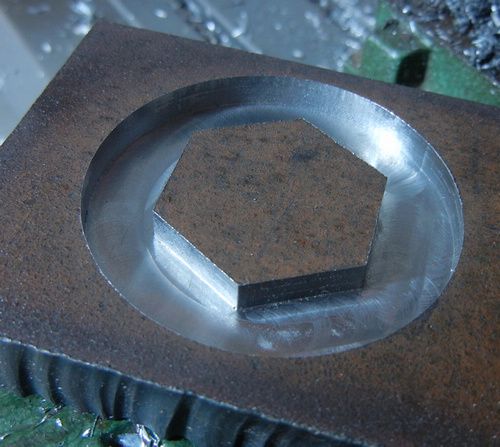

a. firstly I generated a G code to mill a 6mm hight, 30mm OD cylinder on the aluminm material. This is a simple way to test many real cutting features of X,Y,Z axis travel accuracy, repeat accuracy and X,Y perpendicularity. Any feature no good will cause the cylinder size big error especially the circular degree. I measured the cylinder hight, OD from many directions to check the cutting accuracy. the measurement showed the actural cutting accuracy is good --- all under 0.02mm. typically 0.01mm. This result declared that the machine system accuracy reached the target of industrial level.

b. Then I tested another program of pocket milling both on aluminum and steel material. I used 6mm end mill tool on AL material and a 8mm end mill tool on steel material. So the ID should be 50mm for AL one, and 52mm for steel one. Here is the cutting results and measurement. The cutting surfaces are perfect smooth and the measurement error is very good too.

Here... all my fruits today

Here are the total results today. So all approving tests are finished now... Next I will organize the datasheet and preparing marketing works. www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-12-2013, 04:38 AM #12

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 3920

I'm on my way to Cabin Fever which is a small engine / model engineering show / auction and a what have you event. Cabin Fever is in York PA, it is too bad you are on the other side of the planet, I suspect many people would love to see this machine there. There certainly is a segment of model engineers that would be interested in a machine this size.

Since I'm in a hotel right now with nothing to do I have a few comments that have been on my mind while on the road.

- Skyfire is certainly a good name for the company that will market the machines but I think you need a system for naming individual machines. In this case the idea came to me to call this machine "SVM-0". For Skyfire Vertical Mill zero. It might seem silly right now but ten years down the road when you have a half dozen machines to sell it might be useful to have a system. Simple names help with customer interface and user communications. For example in the USA if you mention HLV you know exactly what type of machine is being discussed. If you come out with a lathe you might want to name the first one "SHL-0"for Skyfire Horizontal Lathe zero. The model names should effectively link the tools to your company.

- When you first started this thread you indicated an interest in an engraving machine. At that point I don't think anybody was concerned about the column cross sectional size. When refocusing the machine on milling you may have created a problem in that the column could end up stressed more than it should be, this could especially be the case if you go to a much larger ER collet. Due to this issue I'd suggest verifying that the machine can mechanically handle the stress trying to run large tools on the machine might create. This really isn't a huge machine by any measure so I'm not sure there is a lot of value in giving it huge ER capacity. I really see this as a much better TAIG sized mill. This may lead to argument with others but I think your gut instinct was right going with the original ER size. This is especially the case because I you machine easily allows for much higher spindle speeds than run of the mill low cost machines. I'd love a machine that can handle ISO 20 or 30 tapers but I don't think this will ever be that machine. Better to keep focused on a specific market.

- Somebody else mentioned taper lock pulleys for easy ratio changes, that isn't a bad idea as it keeps the rest of the machine simple. Previously I was concerned about low end torque but I'm just not sure this is the machine to leverage big cutters or to dril,or bore large diameter holes. ER collets themselves are a limitation here. Even an RB spindle has more capability to handle odd tooling than ER collets.

- I'm a bit concerned about the machine ability to meet regulations in many countries. Frankly I'm not up to speed with respect to the latest regulations in the USA, but Underwriters and the NFPA each have requirements. OSHA is another problem if you sell to businesses. In the EU countries I'm not sure this machine would fly at all. In any event nobody cares about the EU, you should however get a UL stamp for the machine if it goes on sale in North America. There ought to be some sort of help to get this done in China. Yes this will add to the cost of the machine but I think it is important.

- I really like that you haven't abandoned support for the engraving spindle. This could be a very useful option for the mill.

- Likewise I'm glad to see you have interest still in supporting servos for the axis. It might make for an interesting combination when combined with the engraving spindle.

- If atall possible consider supporting EMC! It is an excellent platform, more importantly it removes the burden of having to run Windows. Further Machs support of lathes is wanting. EMC will allow you to support a wider array of machines in the future.

- It would be nice to have a switched AC outlet (IEC type) built into the machine. This to be tied to M functions most likely for coolant. The outlet should be fused.

- I like the two tone paint! ������. It just looks good in the pictures. Paint is as much about the brand as anything else. If you like it I'd stick with the combo for a long time.

- X travel is very limited on this machine. Again that was most likely fine for an engraver when first thinking about the machine. I probably wouldn't change it on this model but if you decide to build a large machine (SVM-1 for example) you might want to consider a much longer X travel.

- Of course an SVM-1 machine would need to be targeted at a different market with a drawbar spindle and an overall larger size.

In any event that is the list for now, got to get up early for Cabin Fever!

-

04-12-2013, 09:35 PM #13

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi wizard. Thank you for your great points here! Yes, It's really a pity that I'm on the other side of the planet.. It will be much better if the earth is a village..

I suppose those model engineers will review this forum if they are looking for a good modeling machine...

I suppose those model engineers will review this forum if they are looking for a good modeling machine...

I agree that "Skyfire CNC" will be the best name from your suggestion and "SVM-0" as the individual name of this one! It's a good idea and I think I can just follow your advise!:cheers:

I decided the ER25 spindle basicly consindering the machine size and cutting capacity also. I think ER25 should be the most fitful size to this machine until handlewanker brought the QCT issue. I think even go with ER32 we should also be carefully about the tool size selecting. Too large tools are obviously not fitful and I think not too necessory too. During my real cutting tests I concluded the column is stiff enough for milling capacity. When I develop a bigger type one, I think I will go with R8 spindle and a strongger column design.

I think the high speed range with 2:1 ratio pulley and work with small tools is more important than lower end torque now. I have proved that the machine can handle steel cuttings with 8-10mm tools no problem. I think this the fitful tool size for this machine with enough torque. taper lock pulley will be good for easy exchanging. This will be a probable develop next but need some support from spindle motor supplier side. This will only be possible unit I have many pcs orders.. I have some similiar but easy ideas too and will be no problem in the motor speed range without dynamic balance.

I know something about the regulations in different countries. This will be a formal issue when I really get strongger business. At the begining, I may not be able to get the certifications because of the cost issue. I'd like to get some other way out like selling the machine as a "kit" But I'm sure the the machine electric system is not any less than the regulations. I would like to get some local dealers in different areas then and solve such problems together. I have many experiences to export similiar CNC machines to US and have no problem.

Various optional accessories like the electric spindle will always be a concern to me. I will do my best to provide satified machines to individual users to meet their needs. Next most urgent project is to develop a 4th axis set for this machine when begining the business.

Servos are always the optional item in my mind. Stppers are most economic and enough for most jobs. But I know many people would like to cost some more money for Servos. I provide this option too..I have the right resource of BLDC/DC servo driving parts... So this is not a problem too.

Certainly the machine will support EMC without problem. the IO channels on my controller board actually can accept signals from any upper computer even MODBUS controller. It's just pulse/direction signal interface. A simple jumper on the controller board can ignor the MACH software charge pump function and accept other signal resource. And users can add in their favorate controller also..

I left a space inside the electric case that can be used to install the relay board to control anything like coolant pump... And my controller board provide the relay control interface also.. I think it's a easy thing to do.. Thank you~

I like the color way myself...I think this two tone color way will be my brand machine choice.

I understand about the X traveling range issue.. I'm considering the optional choice of a longger worktable also to provide maybe 10" travel range. But too long worktable will more trend to transform and cause accuracy drop. So I think 10" travel should be the max for this machine.

Yes. I think future SVM-1 will be a different thing that may not fitful to home users but more of a shop users. It should be more traditional with drawbar spindle and larger size to handle different level works.

I hope you have great fun there today!:cheers:www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-12-2013, 05:17 AM #14

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Sky, well the proof is certainly in the pudding......cutting steel is the proof I need to know it's capable and able to handle all materials without any deflection or shuddering from the column.

The ultimate judgement here is that all the tests were carried out cutting dry, no coolant etc, so if coolant were also present the cutting ability would be even better.

Alluminium does tend to get soft and sticky when cut dry, fast and with force, and it doesn't help the process when the ally gets coated onto the tool causing more friction and heat.

I agree with the problem of supplying an enclosure for the finished product......maybe a plan of a suitable design could be posted, but most people will no doubt make their own if needed.

Personally, I have thought that a dedicated DIY stand with an acrylic type enclosure would be the answer.

A stand made from 50mm X 25mm square steel tubing and having a large angled sheet steel raised rim 150mm high around the edges, with the acrylic shield dropping down into it sealed at the edges all round, and a sliding door at the front for access.

If the bottom of the floor of the stand, where the mill sits on, has each side open to allow swarf and coolant to fall through to a collection tub inside the cabinet, this would make clearing the swarf and draining the coolant easy.

I don't think compressed air is a good idea where precision sliding members are present, so I probably would have mist cooling for the cutter and job and a loose manual hose for flood coolant to flush the chips off the job and down into the bottom of the cabinet.

At any rate, coolant would be an option to be added etc, and with coolant and swarf in abundance, an enclosure is a very big second must have feature, otherwise you'll be wearing it big time.

I don't think soluble oil type coolant is a good idea, although simple and cheap, it does deteriorate rapidly and the bacterial growth, once present is extremely hard to remove and keep away.....so is the smell of old soluble oil coolant......bacterial growth is contributory to dermatitis, where if you get it you have to have total skin protection for ever more.

I would expect to pay some more for a synthetic type coolant, the pale green stuff, as it has qualities far in advance to simple soluble oil.

One thing I will strongly advise, and that is coming from a background of occupational health and safety......DO NOT UNDER ANY CIRCUMSTANCES USE CUTTING OIL FOR COOLANT OR TOOL LUBRICANT, that is unless the cutting oil, (the stuff that resemble dark brown gearbox oil) is supplied in a continuous flood, and not dabbed on with a brush or spray bottle, and is ventilated to remove the fumes that occur.

Many years ago an occurrence occurred where an employee obtained a new unused drum of obsolete to requirements cutting oil used in a Mikron Haesler rotary transfer machine, and as the oil was top quality it was thought to be suitable for everyday DIY lathe work as a drip feed/dab on coolant etc.

Cutting oil, with all it's additives, if allowed to fume when it gets hot without a flood, gives off a smoke that causes flu like symptoms and eventually by long exposure is contributory to emphysema etc.

I had a sore throat for three months before the effects were traced back to just one nights lathe work with that oil.

For that matter, all coolant fumes should be vented.

Now we must wait for the bottom line cost.....with bated breath....LOL.

Ian.

-

04-12-2013, 09:59 PM #15

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi handlewanker! The cutting steel capacity is certainly proved now! The machine didn't get shake or made abnormal sound like a old car

The cutting process was stable only with the cutting sound and the loose vise handle noise. The column showed strong too and the cutting pattern proved to be very smooth.

The cutting process was stable only with the cutting sound and the loose vise handle noise. The column showed strong too and the cutting pattern proved to be very smooth.

I will upload the videos tomorrow.. I need my friend upload them to Youtube for me...But today the aluminum cutting video is avaliable and I will post now

The important issue here, as you said, all of the cutting tests were dry cut. It's really some bad cutting conditions making the cut hard. I'm sure with some coolant it will be even better. So I think my tests were under some most difficult conditions then.

I think it will be some DIY fun to build a enclosure for it on user end. A simple tray or some "delux" enclousre as you said. I will be no problem to provide finished enclosure with machine.. or provide enclousre solutions.

Coolant will be very easy thing to add on the machine. And controled by M code with a extra relay board connected to the controller. I will provide the relay board, or user can make by themselves because it's pretty easy thing to DIY.

I don't know much about the coolant type. But I quite agree that the soluble oil is pretty bad...I used it before and will never touch it again I'm sure we should listen to your suggestions from many experiences here!

I'm sure we should listen to your suggestions from many experiences here!

I will get the last cost very soon.. just working on many optional items now.. I think the basic price will not have much change www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-12-2013, 07:31 AM #16

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Wiz, a good number of points you made.

I personally would like an R8 with draw bar for the spindle, mainly to emulate the Tormach system of TTS, but as that means a spindle with a long hole through it, this is probably complicating the issue for the supplier, but in that case I would go for the ER 32 collet end as it allows the max size of 20mm diam for parallel shank tooling to do QCT set ups and also emulate the TTS method, while at the same time being able to hold bigger tools for lighter machining, like fly cutters or boring heads........even a 5 tip facing cutter could be used with discretion, but I don't think it would work on a 20mm shank, so that would not be a must have.

The machine must still be used within it's capacity, no matter what cutter combination is envisaged, but a smaller shank size is not one that I would want to go downsize on.

The whole point of having this machine is, there is nothing like it on the market that would approach it's capability and match the price, especially if you compromised and bought a same size current bench top manual mill, and wanted to convert it to CNC.

The table length "could" be a bit longer and the saddle travel too, but now we're looking at the next machine build, and if the table was an issue I'm sure a longer one could be supplied as an option for those that needed it, as all it needs is a longer casting and longer rails/ballscrew etc........the saddle travel would mean a complete new base longer casting, not really practical.

I like the colour too, it grows on you.

Ian.

-

04-12-2013, 10:04 PM #17

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Here is the Skyfire CNC mass material removing demo video. Still did that under JOG mode.

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-13-2013, 12:47 PM #18

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Here is the CNC cutting demo videos:

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-13-2013, 12:48 PM #19

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-14-2013, 03:43 PM #20

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 3920

Nice videos!

You really have me reconsidering doing a CNC conversion. I don't see anyway to achieve the quality this machine demonstrates, here in the USA, at the price you are asking. I'm good at scrounging too but a conversion would cost me considerable money and still not have the features your mill has.

I hope you get your web site up and going soon with all of the documentation.

Similar Threads

-

Show us your machine stands

By OHLEMANNR in forum Benchtop MachinesReplies: 7Last Post: 05-05-2013, 03:19 AM -

a machine design (pics) from beginning to end

By blurrycustoms in forum Vertical Mill, Lathe Project LogReplies: 42Last Post: 04-25-2013, 02:36 AM -

dry build or glue from the beginning?

By Ezra in forum Joes CNC Model 2006Replies: 2Last Post: 10-29-2010, 04:44 AM -

Newcastle: Beginning of build plan

By pippin88 in forum Australia, New Zealand Club HouseReplies: 7Last Post: 09-16-2010, 10:22 AM -

Beginning to build my Z-axis.

By zonk2 in forum DIY CNC Router Table MachinesReplies: 0Last Post: 12-23-2008, 06:17 AM