So after lots and lots of research, i'm finally getting the ball rolling on my CNC conversion on my HAFCO HM48 geared head machine. After a lot of research i setteled on the HM48, i had a few key aspect it had to have, Single phase (230v) and a geared head. and within my price range.

Machine details.

Table Size 820 x 240mm

Column Type Dovetail

Longitudinal Travel (X-Axis) 540mm

Cross Travel (Y-Axis) 185mm

Vertical Travel (Z-Axis) 410mm

Type of Slides Dovetail

Spindle to Table 490mm

Quill Travel / Diameter 120mm / 75mm

Drilling Capacity 31.5mm

End Milling Capacity 28mm

Face Milling Capacity 80mm

Spindle Speeds Vertical (steps/rpm) 6 (95-1600rpm)

What I'm about to purchase just hoping for some feedback.

X,Y, & Z stepper drives are going to be NEMA 34 1200oz drives direct for x&y 2-1 reduction on Z axis i will not be motorizing the Quill leaving it standard.

Drivers

KL-870D 70vdc/7a Digital 32bit DSP based

Breakout board

C11 from automationtechnologiesinc.com

I plan on getting the 4 axis up and running later down the track.

Im not to bad on autocad, so i might stick to that, i have decided on mach3 as the driving software - but yet to decide a cam software.

Ive taken all the measurements on the new ball screws and just put the order in for 2505 with bk-bf17 ends.

Im really hoping i can get any feedback that will help before i order the drives, or even better if there is any one local to Mackay QLD that has done a CNC conversion id be very appreciative to talk to someone local, learn as i go!

Results 1 to 20 of 92

-

08-10-2014, 12:13 AM #1

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

HAFCO HM48 geared head CNC conversion

-

08-12-2014, 01:24 PM #2

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 70

Re: HAFCO HM48 geared head CNC conversion

Looks very, very similar to an RF45 (generic name) machine.

You will be able to find a wealth of information about converting this on this forum - just give it a search.

-

08-13-2014, 08:19 AM #3

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

After a bit of research i think it is very similar to HM45 maybe just a bigger Bed by the look of the photos,

Well the ball is rolling, Ill try and keep updates coming on the build as for any reference drawings ect.

I've pulled down the X & Y Axis apart, after many test measurements I've settled for a 20-05 ball screw set ( I iwanted 25, but due to limited room between x & Y slide i am limited to 20mm), this should only be a few days away

I've sourced a Monitor and made up an enclosure this will extend into keyboard mount aswell once i find a suitable unit.

Cut out template

Folded and welded

i started to draw up new ball-screw bearing ends using the original mounting points, but found every hole was not square, infact they all look to be just drilled and pinned with no uniforimty at all, all X & Y axis bering housings were miles of, as pictured below

Look at the top holes each side and see just how far off they are.

-

08-14-2014, 10:22 AM #4

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

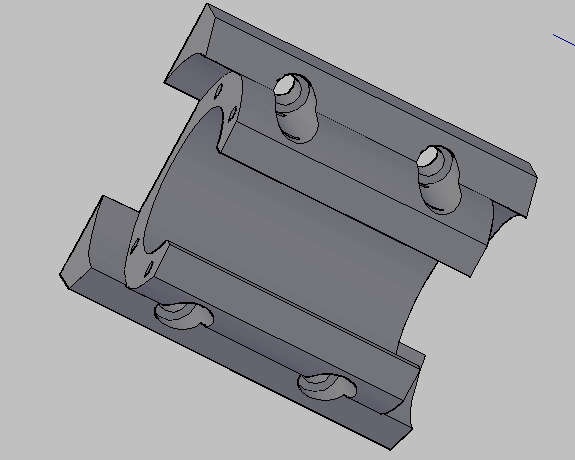

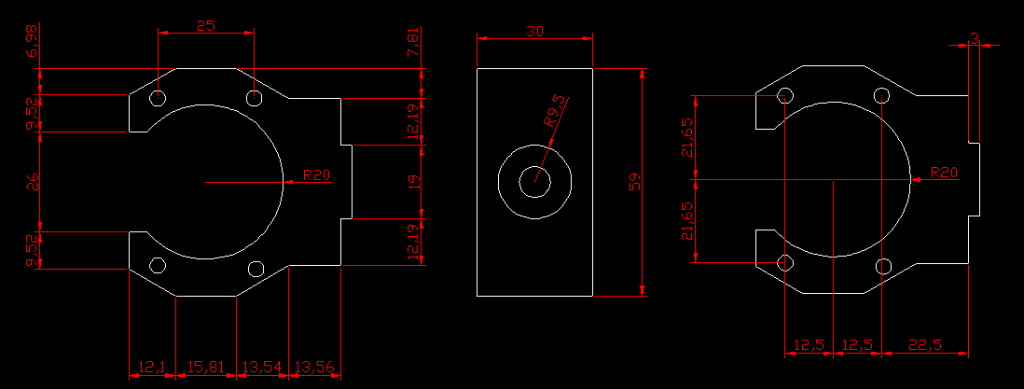

X-Axis ball screw mounts, got a quote at the local machine shop $800 fir 2 items. So i need to find another way to make the items cheaper.

Y-Axis

Please be aware i have not tested these yet so if you use these dimensions, please check this for yourself before using.

-

08-15-2014, 04:06 AM #5

Member

Member

- Join Date

- May 2008

- Posts

- 1185

Re: HAFCO HM48 geared head CNC conversion

It looks like that mill is a real RF-45.

It should say Made in Taiwan somewhere, also the table has 4 slots like most 45 and the ZAY clones have 3 and the gear shifts on the 45 are more level.

The Z screw is held with a bearing block at the bottom front of the column, most clones use the side and last the X nut holder has 4 bolts and a clone mill has two.

It should be a re labeled RF-45.

I could do those two parts for $400 just because I like you!youtube videos of the G0704 under the name arizonavideo99

-

08-15-2014, 05:05 AM #6

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

Thanks for the offer mate, i'm in Australia, so might be a bit hard otherwise i would have taken you up on that, I've bolted it all back together to start making the parts myself, and not enjoying it!! I've got another guy quoting it at the moment.

-

08-15-2014, 09:48 AM #7

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: HAFCO HM48 geared head CNC conversion

Part of the high price might be how you have it drawn?

Might sound dumb.... but you wouldn't beleave how much the price of a part can change depending on how it is drawn and tolerances (or lack there of)

Might sound dumb.... but you wouldn't beleave how much the price of a part can change depending on how it is drawn and tolerances (or lack there of)

On the Y axis mount, I see that being a 3 setup part as long as the angles on the outside can have a radius where it meets the flats (would be an inside radius). As is its at least 2 more setups.

Now the X mount is where I see most of the cost coming from! Again a few changes could make is cheaper (maybe). I could see that one being three setups as well.

I'd ask the places doing the quotes what would make them cheaper as well. Usually a good quoting person will have experience out on the floor and know their s#it!

Andrew

-

08-15-2014, 10:18 AM #8

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

It gets worse i got an $1800 quote back today from another place the x Axis i've taken all the rounding out and simplified it a lot (In saying that that's what the quotes were for as well not the fancy bit i have drawn, i was even doing the drill and tapping),

I do live in a town that is very mining based and so out of touch with pricing. Its starting to look like ill have to make it by hand, one machine shop can bore the holes for me which will save a great deal of time. and only cost me $50 for the bore.

-

08-15-2014, 11:18 AM #9

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: HAFCO HM48 geared head CNC conversion

I had seen a thread where someone made some delrin antiback lash nuts for stock screws. might be a good idea to do a conversion in steps starting there and then cnc the x and y. then start making the new mounts for ballnuts and screws. time consuming, but cheaper i would think?

Andrew

-

08-15-2014, 11:55 AM #10

Gold Member

Gold Member

- Join Date

- Aug 2006

- Posts

- 1602

Re: HAFCO HM48 geared head CNC conversion

What other equipment do you have access to? If you have a lathe, then boring out those big holes in those bearing mounts shouldn't be too bad. Otherwise, as others have suggested, I would consider CNCing using the stock screws, just to make rough and ready versions of those mounts. You can even just go 2 axis if you have an accurate method of measuring the Z-depth, but IMO 3-axis on stock-screws is going to be a bit safer, as you won't disagree with the computer

You won't get pretty parts using the acme screws, but you should get parts that fit well enough - you don't need the bores to hug the ballscrews, you just need clearance as they are flange mounted. Getting the flanges square to the bore is easily done manually or with CNC on stock screws. Once you have the Mk1 mounts, you can fit your ballscrews and either finish there, or cut some Mk 2 mounts with your more accurate screws.

Good luck, and please keep the pictures coming :cheers:

-

08-15-2014, 12:19 PM #11

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

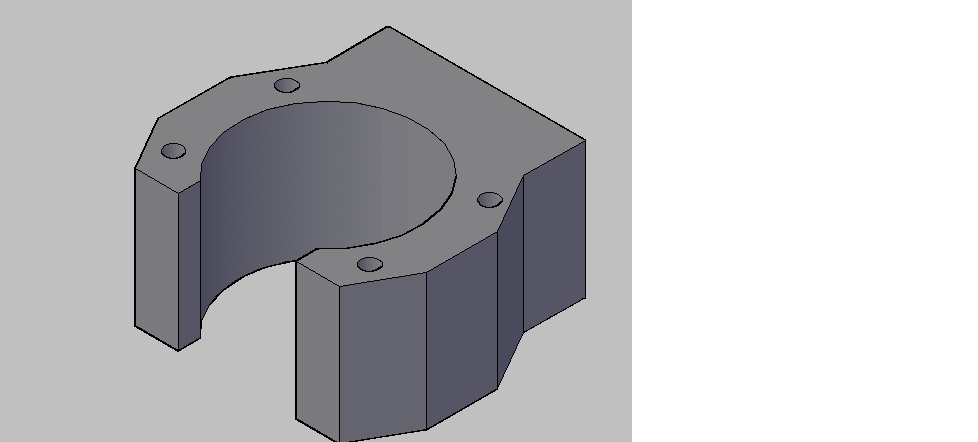

Thanks for the ideas. I've sort of come up with a solution, sort of!!, utelising the ball screws still, i'm simply going to weld some tabs to some bored 60mm round bar, make them as close as i can with the tools i have. My Lathe is a tiny little thing only got a 25mm bore through the head stock. Z axis i have a fairly accurate way of measuring, I always planned on making the mounts for a Z Axis ballscrew once XandY axis are computer operated.

-

08-16-2014, 09:05 AM #12

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

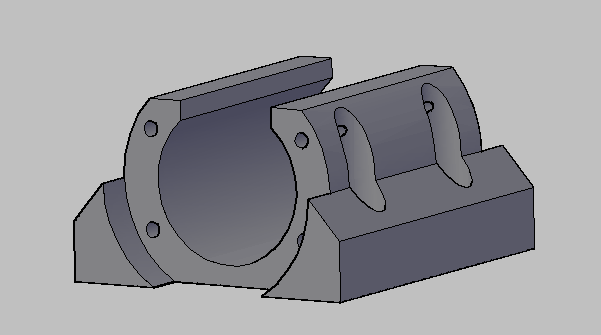

Y axis mount.

So it's pretty obvious i am no good at this machining, learning on the way, first time 'Ive really used it for anything other than facing exhaust manifolds.! modified it a bit to allow the flange of the ball screw nut to seat inside it. I Totally ruined 4 flute mills!! it seems bigger is not always better, the 10mm seems to work well. and ive slowly figured out what way i need to cut !

need to machine the rest of it in a 4 jaw chuck

-

08-16-2014, 11:20 AM #13

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 108

Re: HAFCO HM48 geared head CNC conversion

Luv the display housing you made, possible to share the plans for that?

Anyway, looking forward following this and see how you progress, just about to start my own conversion finally.

Good luck, we're in the same boat where the locals rip the pricing, I might consider sending some of it off to a contact in China.

Cheers,

Beano

-

08-16-2014, 11:46 AM #14

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

happy to share any plans i have made for this, leave an email address and i can send it through, in dxf file for laser cutting. be mindful this was made to suit a specific screen.

-

08-16-2014, 01:40 PM #15

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 108

Re: HAFCO HM48 geared head CNC conversion

Thanx Mate, will PM my address to you

I can adjust it to suit if necessary!

Cheers,

Beano

-

08-19-2014, 09:40 AM #16

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

wooo hooo, my drives power supply, and breakout board, arrived today from usa. Ball-screw should show up tomorrow. Very happy with the packaging, and freight time from Automation Technologies. and the gear all looks very good quality. cant wait to get this up and running.

-

08-19-2014, 10:04 AM #17

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 108

Re: HAFCO HM48 geared head CNC conversion

Nice progress, I know the feeling

My DMM-Tech AC servos and drives, breakout board et al showed up yesterday, and this morning I flew out to Bangkok....unbelievable, blah....

Will hopefully order my ballscrews in the next few weeks, as I still need to strip the machine to get lengths etc...

Pics, please!

Cheers,

Beano

-

08-20-2014, 09:17 PM #18

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

The drives are set up and on the way i forgot to order a bloody parallel cable so i cant test it till I locate one of them. My neighbor donated a computer to the project that has XP on it., pretty happy about that, and the local B&E rep is supplying an ex demonstration enclosure for free. super happy about that!!

here is a little video i made, there is a few questions i have. if you know the answers, I'd love to hear them.

and yes i know i keep saying serial cable!!

http://vid908.photobucket.com/albums...pse28bcdbe.mp4

-

08-21-2014, 11:40 AM #19

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

And I have it going

had it all wired up correctly just had a programming issue. Next time I'll read the instructions first!! Basically i had not selected the Safety charge pump output (pin 17) but yeah happy moment!!

had it all wired up correctly just had a programming issue. Next time I'll read the instructions first!! Basically i had not selected the Safety charge pump output (pin 17) but yeah happy moment!!

https://www.facebook.com/photo.php?v=10204439999337096&l=306580325999544541 7

-

08-21-2014, 02:06 PM #20

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 70

Re: HAFCO HM48 geared head CNC conversion

In regards to the video: There should be no problem whatsoever with bridging the two outputs on the PSU. In some power supplies I've seen, the two outputs have grounds that are not connected - this lets you put the two outputs in series, doubling the voltage (I have no idea whether this is the case with yours).

As for the Z heat, check that the DIP switches on all the drivers are matched (specifically the current selection).

Similar Threads

-

CNC Conversion Help Needed - Harbor Freight Geared Head Mill Drill, Model# 42827

By TurdCurd in forum Benchtop MachinesReplies: 2Last Post: 08-07-2014, 03:17 PM -

Hafco CNC Conversion

By Johnnysilk in forum Australia, New Zealand Club HouseReplies: 8Last Post: 04-16-2013, 09:30 AM -

Lubricating Geared Head Mill

By stabbs in forum Benchtop MachinesReplies: 6Last Post: 08-17-2009, 10:43 PM -

Geared head vs. Belt drive Band saw

By ranchak in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 10-16-2008, 04:25 AM -

Want to quiet your Geared Head?

By fineartlig in forum Charter Oak Automation Support ForumReplies: 2Last Post: 10-09-2007, 03:12 AM

Reply With Quote

Reply With Quote