Has anyone tried this floating engraving tool? I'm looking to engrave simple letters for serial numbers and basic text font engraving on anodized aluminum parts. This looks like it would easily fit on the 1100 spindle and it would be simple to TTS that 3/4" version. The recommended feeds and speeds look to work well with the standard 1100 spindle, without even needing the speeder to get pretty close to optimal feed rates. It can easily be used with flood coolant to keep tool life high too.

Looks like a good solution for what I'm looking to do without the need for an aux. spindle or speeder.

Spring Loaded Engraving Tools engrave flat and uneven surfaces

Thread: Engraving on the 1100

Results 1 to 14 of 14

-

01-15-2011, 10:29 PM #1

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 156

Engraving on the 1100

-

01-15-2011, 11:04 PM #2

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 154

I have not tried it but I made a diamond drag holder for myself and it works very well. If diamond drag would work for you and you don't want to spend the time making one, you can buy some much cheaper one on ebay too (search for diamond drag engraving). The difference with the one you showed us, is that they are not made for the spindle on. So they would not work with a regular engraving bit. Diamond drag is fast, simple, produce nice fine and shallow lines. Should work well on anodized aluminum. And diamonds are forever!

-

01-15-2011, 11:07 PM #3

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 154

By the way, got the probe this morning! Thanks.

-

01-16-2011, 05:49 AM #4

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 156

-

01-16-2011, 11:28 AM #5

Gold Member

Gold Member

- Join Date

- Jun 2006

- Posts

- 2512

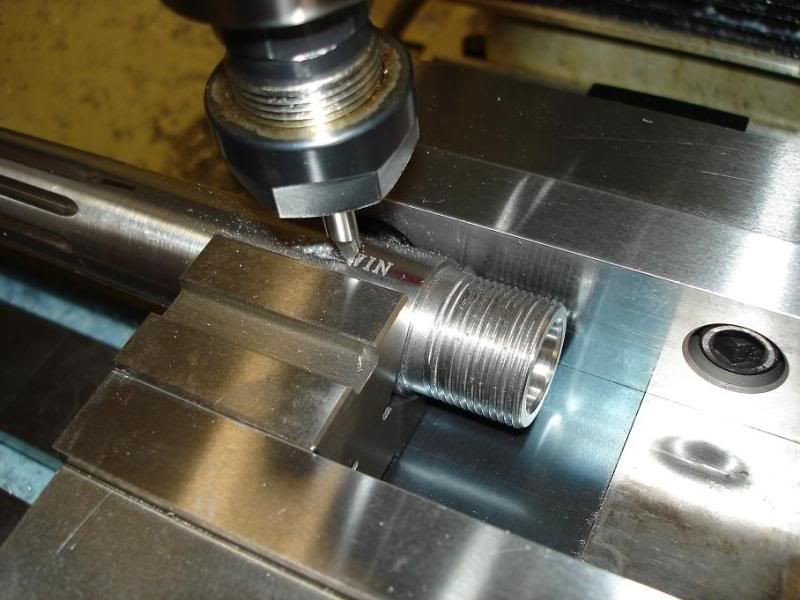

Why waste $345. This was done with a 60 degree carbide engraving cutter in an TTS ER20 collet holder at 4,200 rpm.

Phil:

-

01-16-2011, 05:36 PM #6

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 438

but that also involved setting up and programming a 4th axis. for what i do a lot of, this tool would be very handy, provided it works as it should.

99% of the engraving i do is .125" tall text on the od of a 1.2" od cylinder. .125" is about the limit before i would have to start using the 4th axis. if this tool works, i could go to a larger text without the hassle of installing and removing the 4th axis. i also could continue using the "text" wizard that comes with mach.

-

01-17-2011, 12:11 AM #7

Gold Member

Gold Member

- Join Date

- Jun 2006

- Posts

- 2512

I don't see how a spring loaded tool makes any difference when cutting text on a curved surface, or am I missing something.

Phil

-

01-17-2011, 02:47 AM #8

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 176

spring loaded Engraver

We have the spring loaded engraver. Depth of engraving is controlled by feedrate, rpm and the spring. The piece works well if you want to engrave on surfaces that are not totally flat, it keeps the depth of engraving (and therefore the line width) constant. Engraving on round surfaces does not work if you get too far off center, it shows in the engraving itself. I'd say 15 degrees between table and the surface is the max.

Engraving anodized Aluminum will give you feedrates of 10-15 ipm and if you want to engrave longer texts/signs/drawings it will be time consuming.

We use it for machine front and back plates where we have a hard time mounting it down flat. If we have a flat surface we only use the engraving mill in a regular TTS holder.

The software that comes with the package is more or less useless to us. The number of fonts is rather limited and the import of dxf files has always caused problem for us. We de-installed it after a short period of time and went with the solutions in our CAM program(s).

Hope that helps.

benji

-

01-17-2011, 03:30 AM #9

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 156

That helps..... the type of input I was looking for.

Most of what I need is a logo engraving.... maybe 3" long in .75" tall text. I also need to do basic text on flat material for labels and serial numbers engraved into the aluminum.

I think the suggestion to just try a standard bit first is a good suggestion for me. In the vast majority of situations I am working on flat material.

-

01-19-2011, 11:23 AM #10

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 92

I did some engraving for the first time a couple of weeks ago using an 1/8" carbide engraving tool and the wizard in Mach 3. I reckon it came up quite well.

-

01-19-2011, 04:53 PM #11

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 154

-

01-21-2011, 06:30 AM #12

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 151

I have a 2L engraver and it works extremely well for light cut engraving especially on surfaces that are not flat including round stock and thin stock where once you clamp down the sheet... it tends to warp a little on the table. I also use a 1/16" Endmill on a TTS holder if I'm engraving deep (1/16" or more) but the stock has to be pretty solid and flat. Below are a few things I've engraved with it. If you engrave a lot... I highly recommend it... it is pricey but I think it's worth it.

Ken

-

01-21-2011, 07:34 AM #13

Registered

Registered

- Join Date

- Oct 2006

- Posts

- 137

Concombefrais, that isn't a Koala it is a Wombat and you don't have to hunt them, they just walk out on the road themselves and get killed! Just don't hit one at high speed in a small car.

Will

-

01-21-2011, 08:37 AM #14

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 92

I've got one that wanders out from under my bed and attacks my ankles every time I wake up

They're one of the funniest animals around.

They're one of the funniest animals around.

I watched the video of that engraving tool, it would be a handy bit of gear. I ruined one part last night engraving it because it wasn't perfectly flat, wouldn't have been a problem with that tool..

Similar Threads

-

1100 on it's way

By Etced in forum Tormach Personal CNC MillReplies: 11Last Post: 01-03-2011, 09:52 PM -

PCNC 1100 help

By jedge in forum Tormach Personal CNC MillReplies: 6Last Post: 10-23-2010, 11:58 PM -

Who wants the 10,000 rpm spindle for the 1100

By pzzamakr1980 in forum Tormach Personal CNC MillReplies: 10Last Post: 03-05-2010, 07:11 PM -

Anilam 1100

By english bob in forum CNC (Mill / Lathe) Control Software (NC)Replies: 2Last Post: 02-09-2008, 04:12 AM -

anilam 1100

By tmt_92021 in forum MetalWork DiscussionReplies: 1Last Post: 07-09-2006, 05:28 PM

Reply With Quote

Reply With Quote