Hi guys,

Thought I would share some photos and videos from my machine build - a variation of the G0704 mill is available from Titan Machinery here in Australia. After seeing HOSS's amazing work

I chose to follow a similar route.

After I fitted the CNCFusion kit - my mate Aaron helped me clean up the castings and modify as required.

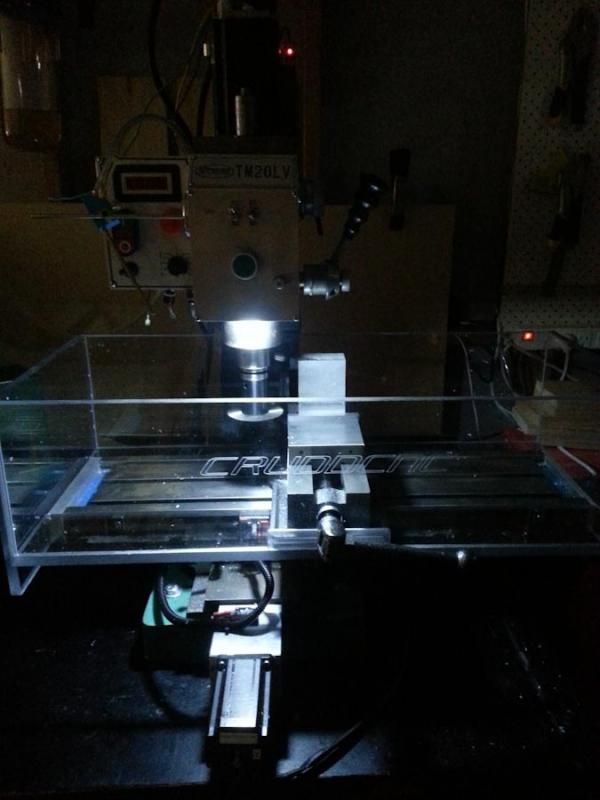

Spindle LED and tools:

Polycarbonate enclosure helps keep chips in the packet:

CNC Mill Polycarbonate Table Enclosure Test - YouTube

Some parts I have made:

CNC Milling - adaptive clearing - YouTube

CNC Mill - Billet aluminium iPad stand project - YouTube

Next up is belt drive and power draw bar. I bought the plans from HOSS. Changed to make air cylinder spring to close.

This is all still work in progress so will post up some pictures as I plod along

Cheers

Luke

Thread: Crudd TM20VL

Results 1 to 20 of 28

-

04-07-2013, 10:27 AM #1

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 12

Crudd TM20VL

Crudd TM20VL

-

04-07-2013, 04:17 PM #2

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 124

Beautiful work.

-

04-07-2013, 05:11 PM #3

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 38

Great job! I really enjoy watching your videos.

Isn't that polycarbonate box going to limit your space? How does the polycarbonate like chips, gets scratched easily? I've been thinking about making smt similiar.

-

04-08-2013, 01:04 PM #4

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1532

Nice work!

Where are you based?

I have a TM20VL also, looking at converting it in the long term. Was the CNC fusion kit fairly bolt in? Because there are a number of differences vs the G0704.

Cheers,

Nick7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

04-08-2013, 02:01 PM #5

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Awesome work Luke and nice mod on the cylinder.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

04-09-2013, 11:35 AM #6

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 12

Thanks all for the feedback and to HOSS for all of the information you have provided!

Madda - the polycarbonate isn't scratched up (yet) but may become over more sessions

Pippin88 - cheers mate I am in Melbourne. I had some difficulty with the kit and cannot recommend it for this mill. The differences are too significant for it to be bolt on.

Getting home from work offshore soon and going to attach the belt drive first up. Scott at Benchtop precision has sent a prototype to fit. Then will see if I can get

the power draw bar in the works. Exciting times ahead!

-

04-19-2013, 12:17 PM #7

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 12

Back from work and starting on the mill again. Belt drive kit from benchtopprecision fits very nicely. Max spindle RPM now 5000. Also replaced the bearings.

Problem is I need to re-design/make one part for the power draw bar setup now! bit of a set back...

-

04-22-2013, 07:33 AM #8

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 1096

Hi Luke,

Great Build. We may have to meet. I'm also in Melbourne, and converting a TM20VL myself. I'm doing a belt conversion. Not sure why other than it gives me some flexibility with motor sizes and the option to use servos.

Once I get the conversion done, my next step is to do a power drawbar. I too have Hoss's plans.

Nick, Have a look at my thread as it shows a scratch built conversion. It's been put aside for a month or so as I've got too many other things on. It should give you an ideas as to what is involved. I should have the dxfs I used for the conversion parts, which should reduce some of the measuring required.

http://www.cnczone.com/forums/bencht...onversion.html

Cheers,

Peter.-------------------------------------------------

Homann Designs - http://www.homanndesigns.com/store

-

04-22-2013, 02:57 PM #9

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 60

Every time I go to the benchtopprecission website and try to purchase a belt drive kit the website always says "Coming Soon" and has no pricing info or much more information.

How were you able to acquire one of these?

what was the cost?

what did it contain? what it didnt contain?

I just sent them an email, hope to hear back from them.

-

04-23-2013, 05:30 AM #10

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 12

I was lucky enough to receive a kit for test fitment provided by Scott - he is still in the prototype phase.

The kit comes with spindle sleeve to accommodate driven pulleys and RPM wheel, belt, drive pulleys and mount including all hardware.

Best if you email Scott to find out availability.

Hi Peter I have also been following your build as you update on your website, sometimes I drop in to buy things there where abouts are you located? I am in Mornington.

where abouts are you located? I am in Mornington.

Cheers

-

04-23-2013, 07:49 PM #11

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 139

Just a word on the BF20 belt drive. I'm up to my ears in X2 belt drive conversions at the moment and have had little time to work on the BF20 belt drive. Everything is moving along and it looks like Luke's fits nicely. I will post more information as soon as I can. Please be patient, they are coming. I don't want to hijack this thread so I'd be happy to answer any questions via email.

BTW nice looking machine Luke.

-

04-24-2013, 03:44 AM #12

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1187

Yeah great work!!! Love the RC heli , freakin bad ass!!!!

-

04-24-2013, 07:42 AM #13

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 12

I have bee running the mill consistently for the past few days - the belt drive kit has really improved the finish of the parts.

Here are some fixture plates to go on my router - they are to hold down polycarbonate material which makes multi-rotor parts

Really need auto tapping head...

Also made an adapter for this 3 axis stabilized camera gimbal, so it can be held by hand. I should have enabled backlash for this part, going to have to make another one.

-

04-30-2013, 07:59 AM #14

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 1096

Hey Luke,

Can you share some of the details on how you fixed the Z-Axis bearing plate to the column? From what I can see on my machine there is not a lot of meat there.

Cheers,

Peter-------------------------------------------------

Homann Designs - http://www.homanndesigns.com/store

-

06-14-2013, 01:22 PM #15

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 12

Hi Peter,

There isn't a a lot of meat there you are correct, I was able to use the existing holes at the rear of the column I believe, just two bolts has been sufficient

Here's a bit of an update.

DIY CNC TM20VL - Belt drive - YouTube

Tomorrow I will try my power draw bar and report back.

Thanks to HOSS for sending me the STL for the spline spacer. Works well and really eliminated the rattle!

-

06-15-2013, 12:24 AM #16

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 139

Hey Luke,

Thank you for your kind words and I'm glad you like your kit. One correction though, I will be producing these kits for the BF20 series mills at a point in the near future.

-

06-15-2013, 02:53 AM #17

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1532

Luke,

How high are the walls on your chip guard? Does much escape? Any changes if you were to re do it?

I needed to make one to contain the mess.

Cheers,

Nick7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

06-15-2013, 10:14 AM #18

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 12

Hey Nick, they are 180mm from memory but I will confirm that. I would say it contains 90% of the mess. If I am fly cutting something tall, then most of the chips will escape - I am considering adding some hinged flaps which can be folded up higher, and keep those pesky ones inside.

Cheers

Got the power draw bar working today. Thanks HOSS for making the information available.

I had to change the design to suit my belt drive pulley.

For the second time I have ordered the wrong solenoid. I have 3port 2 way valves, but they do not work as I expected.

I need the valve to deliver air when solenoid energized, and then exhaust the air from that line when DE-energized. The manual valve I have does this.

If anyone can help here that would be greatly appreciated

DIY CNC TM20VL MILL - Power Draw Bar fitted - YouTube

Very happy at the moment. Now I just need to enter all tool offsets into mach tooltable

-

06-15-2013, 02:22 PM #19

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

What you want is one of these:

DC12V Solenoid Air Valve 5port 2position Inlet 1 8"BSP 4V110 06 Inner Guide Type | eBay

5-port, 2-way - Pressure In, Two outlets, Two exhausts. When one outlet is pressurized, the other is exhausted, and vice-versa.

I'm pretty sure the terminology on solenoid valves was specifically designed to be maximally confusing....

Regards,

Ray L.

-

06-15-2013, 02:45 PM #20

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

http://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

Reply With Quote

Reply With Quote