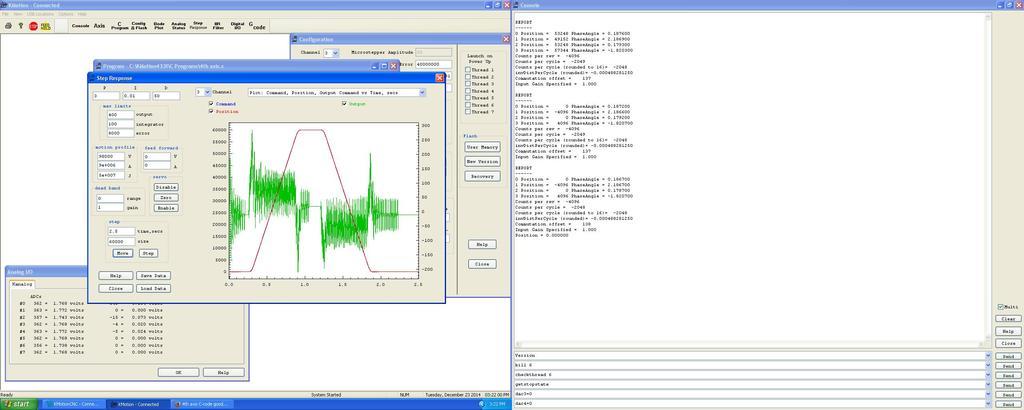

i put together another dual DAC output motor (ac brushless) and drive (copley) to use on my 4th axis. i got the C code put together and seems to work. i just want to make sure it looks good and are not missing something before i start the motor tuning.

i believe i got the commutation offset all buttered up and all the bits and channels right.

Thread: 4th axis C-code good?

Results 1 to 14 of 14

-

12-21-2014, 03:24 AM #1

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

4th axis C-code good?

shizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

-

12-21-2014, 03:46 AM #2

Junior Member

Junior Member

- Join Date

- May 2006

- Posts

- 4045

Re: 4th axis C-code good?

Hi turbothis,

Looks reasonable to me.

Regards

TKTK

http://dynomotion.com

-

12-21-2014, 04:00 AM #3

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

Re: 4th axis C-code good?

great thanks

the tuning was kinda wonky today but i think i can get some work done on it in the morning

mattshizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

-

12-21-2014, 10:01 PM #4

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

Re: 4th axis C-code good?

so i seem to get a little noise or something on my dac2 and dac3 outputs. the motor has a noticeable drag or bumping over as i turn it by hand.

i unplug the dac output wires and this goes away.

the analog output page says no voltage outputting when i feel the drag.?

i get this with both v4.31j and v4.33j

i measure no DC volts with my meter on the dac pins when the drag is present

tuning is garbage and i think it might be due to this issue

hmmmm, loaded v4.33a and now i get an error on the analog screen?

"no options with analog

analog screen closed"shizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

-

12-22-2014, 03:25 AM #5

Registered

Registered

- Join Date

- Jun 2013

- Posts

- 1041

Re: 4th axis C-code good?

At the top of the screen in kmotion exe there is a options menu. Make sure there is a check Mark next to the boards you are using. That is most likely what's causing the no options error.

Ben

-

12-22-2014, 03:40 AM #6

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

Re: 4th axis C-code good?

i deleted my old dynomotion stuff and downloaded v4.33j again and are now back on track.

the 4th axis motor still is very much not responding to tuning.

noise seems to have gone away mostly though

the motor is in the vice for tuning purposes right now. i dont think it would be impossible to get some control with no load on the servo?shizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

-

12-22-2014, 11:46 PM #7

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

Re: 4th axis C-code good?

motor is not too responsive by my hand. i am thinking one of the IIR filters is needed? lol

shizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

-

12-22-2014, 11:57 PM #8

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

Re: 4th axis C-code good?

from the phase find c code

0 Position = 3512 PhaseAngle = 0.494500

1 Position = 3112 PhaseAngle = 4.494800

2 Position = 3512 PhaseAngle = 0.479400

3 Position = 3912 PhaseAngle = -3.520300

Counts per rev = -400

Counts per cycle = -100

Counts per cycle (rounded to 16)= -96

invDistPerCycle (rounded)= -0.010416666667

Commutation offset = -23

Input Gain Specified = 1.000shizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

-

12-23-2014, 03:33 AM #9

Junior Member

Junior Member

- Join Date

- May 2006

- Posts

- 4045

Re: 4th axis C-code good?

Hi turbothis,

I think the issue is with the commutation. Notice how things work pretty well in the plot (red plot follows blue) until after a few hundred counts, then I believe the commutation gets off and the motor torque reverses (green plot goes way positive but red plot goes negative) and the motor drives the wrong direction.

Try with invDistPerCycle set at exactly -0.01

I think the Auto Phase Find program found this exactly correct, but then rounded to a multiple of 16 because most encoders are powers of 2 like 512 counts/ rev. Measuring the number of counts/rev can be off by several counts which is the reason for the rounding. The counts/cycle must be exactly correct otherwise after enough cycles the commutation will eventually drift off to cause a problem. We should probably make the Auto Phase Finding program smarter and try rounding off to multiples of 16 and multiples of 10 and choose whichever is closer.

Make absolutely sure the commutation is correct before proceeding to tuning and other things. When the servo is enabled with the output limited to a small value to allow you to force the motor away from the target position, the restoring torque of the motor should increase to a constant saturated torque level and remain constant regardless of how far away (multiple revs) from the target the motor is moved. This demonstrates the motor is being commutated properly and able to maintain constant torque regardless of commutation angle.

HTH

RegardsTK

http://dynomotion.com

-

12-23-2014, 06:11 AM #10

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

Re: 4th axis C-code good?

nice

i will try this in the morning and report back here

thanks mattshizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

-

12-23-2014, 11:44 PM #11

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

Re: 4th axis C-code good?

the -0.01 invdutypercycle did nothing better. looked worst

i did the phase find a couple times in a row and got 2 different sets of info

REPORT

------

0 Position = -400 PhaseAngle = 0.932200

1 Position = -800 PhaseAngle = 2.931900

2 Position = -400 PhaseAngle = 0.926500

3 Position = 0 PhaseAngle = -1.073600

Counts per rev = -400

Counts per cycle = -200

Counts per cycle (rounded to 16)= -208

invDistPerCycle (rounded)= -0.004807692308

Commutation offset = -141

Input Gain Specified = 1.000

REPORT

------

0 Position = -400 PhaseAngle = 1.928300

1 Position = -801 PhaseAngle = 3.928700

2 Position = -401 PhaseAngle = 1.923700

3 Position = -1 PhaseAngle = -0.077400

Counts per rev = -401

Counts per cycle = -200

Counts per cycle (rounded to 16)= -208

invDistPerCycle (rounded)= -0.004807692308

Commutation offset = -141

Input Gain Specified = 1.000

REPORT

------

0 Position = -400 PhaseAngle = 1.927800

1 Position = -800 PhaseAngle = 3.928400

2 Position = -400 PhaseAngle = 1.923100

3 Position = 0 PhaseAngle = -0.077100

Counts per rev = -400

Counts per cycle = -200

Counts per cycle (rounded to 16)= -192

invDistPerCycle (rounded)= -0.005208333333

Commutation offset = -130

Input Gain Specified = 1.000

REPORT

------

0 Position = -400 PhaseAngle = 1.928300

1 Position = -800 PhaseAngle = 3.928300

2 Position = -400 PhaseAngle = 1.922800

3 Position = 0 PhaseAngle = -0.076000

Counts per rev = -400

Counts per cycle = -200

Counts per cycle (rounded to 16)= -208

invDistPerCycle (rounded)= -0.004807692308

Commutation offset = -141

Input Gain Specified = 1.000

REPORT

------

0 Position = -400 PhaseAngle = 1.928600

1 Position = -800 PhaseAngle = 3.927900

2 Position = -400 PhaseAngle = 1.922600

3 Position = 0 PhaseAngle = -0.077100

Counts per rev = -400

Counts per cycle = -200

Counts per cycle (rounded to 16)= -208

invDistPerCycle (rounded)= -0.004807692308

Commutation offset = -140

Input Gain Specified = 1.000

REPORT

------

0 Position = -400 PhaseAngle = 1.928300

1 Position = -800 PhaseAngle = 3.928500

2 Position = -400 PhaseAngle = 1.923200

3 Position = 0 PhaseAngle = -0.077200

Counts per rev = -400

Counts per cycle = -200

Counts per cycle (rounded to 16)= -192

invDistPerCycle (rounded)= -0.005208333333

Commutation offset = -130

Input Gain Specified = 1.000

REPORT

------

0 Position = -400 PhaseAngle = 1.927500

1 Position = -800 PhaseAngle = 3.928000

2 Position = -400 PhaseAngle = 1.922700

3 Position = 0 PhaseAngle = -0.077500

Counts per rev = -400

Counts per cycle = -200

Counts per cycle (rounded to 16)= -192

invDistPerCycle (rounded)= -0.005208333333

Commutation offset = -130

Input Gain Specified = 1.000shizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

-

12-23-2014, 11:53 PM #12

Junior Member

Junior Member

- Join Date

- May 2006

- Posts

- 4045

Re: 4th axis C-code good?

Hi Matt,

Strange the reports now all show 200 counts/cycle which would be an InvDistPerCycle of 0.005.

Did you change something?

RegardsTK

http://dynomotion.com

-

12-24-2014, 12:21 AM #13

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

Re: 4th axis C-code good?

shizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

-

12-24-2014, 12:27 AM #14

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 230

Re: 4th axis C-code good?

encoder at 1024 setting

REPORT

------

0 Position = 53248 PhaseAngle = 0.187600

1 Position = 49152 PhaseAngle = 2.186900

2 Position = 53248 PhaseAngle = 0.179300

3 Position = 57344 PhaseAngle = -1.820300

Counts per rev = -4096

Counts per cycle = -2049

Counts per cycle (rounded to 16)= -2048

invDistPerCycle (rounded)= -0.000488281250

Commutation offset = 137

Input Gain Specified = 1.000

REPORT

------

0 Position = 0 PhaseAngle = 0.187200

1 Position = -4096 PhaseAngle = 2.186600

2 Position = 0 PhaseAngle = 0.179200

3 Position = 4096 PhaseAngle = -1.820700

Counts per rev = -4096

Counts per cycle = -2049

Counts per cycle (rounded to 16)= -2048

invDistPerCycle (rounded)= -0.000488281250

Commutation offset = 137

Input Gain Specified = 1.000

REPORT

------

0 Position = 0 PhaseAngle = 0.186700

1 Position = -4096 PhaseAngle = 2.186700

2 Position = 0 PhaseAngle = 0.178700

3 Position = 4096 PhaseAngle = -1.820700

Counts per rev = -4096

Counts per cycle = -2048

Counts per cycle (rounded to 16)= -2048

invDistPerCycle (rounded)= -0.000488281250

Commutation offset = 138

Input Gain Specified = 1.000

Position = 0.000000

- - - Updated - - -

i dont think so

that was all at the 400 counts on the encoder settingsshizuoka an-s knee mill=kflop/kanalog running nema 34 dc brushed servos

cincinnati sabre 750=kflop/kanalog building now with ac brushless servos

Similar Threads

-

How to rotate G-code in the G-code (to simulate 4th and 5th axis) or axis indexing?

By Johnsinski in forum G-Code ProgramingReplies: 14Last Post: 07-19-2014, 05:55 AM -

How to work arc good into code?

By panozeng in forum Waterjet General TopicsReplies: 1Last Post: 11-28-2010, 11:15 PM -

Need good code!

By dave6 in forum Mazak, Mitsubishi, MazatrolReplies: 2Last Post: 11-29-2008, 06:01 PM -

Looking For a good cad/cam w/ 4th axis

By fc911c in forum Uncategorised CAM DiscussionReplies: 1Last Post: 10-03-2005, 02:20 PM -

Help G-code No Good

By chrisw765 in forum CNC (Mill / Lathe) Control Software (NC)Replies: 5Last Post: 03-18-2005, 05:55 PM

Reply With Quote

Reply With Quote