About Me

I graduated college with a B.S. in Mechanical Engineering about five years ago and was fortunate enough to find a job as an Engineer. One thing that surprised me about the job is how much actual "engineering" is not required. Most of the time I just plug numbers into a computer program and use what comes out. As you can see, I'm a little frustrated. To vent my engineering outlets I began designing, flying, and manufacturing Remote Control Aircraft. I moved into composite aircraft about two years ago and never looked back. It takes roughly 600-700 hours (depending on size) to make a male plug ready for production. After making a model (figures 1-3) I figured there had to be another way.....

About the Design

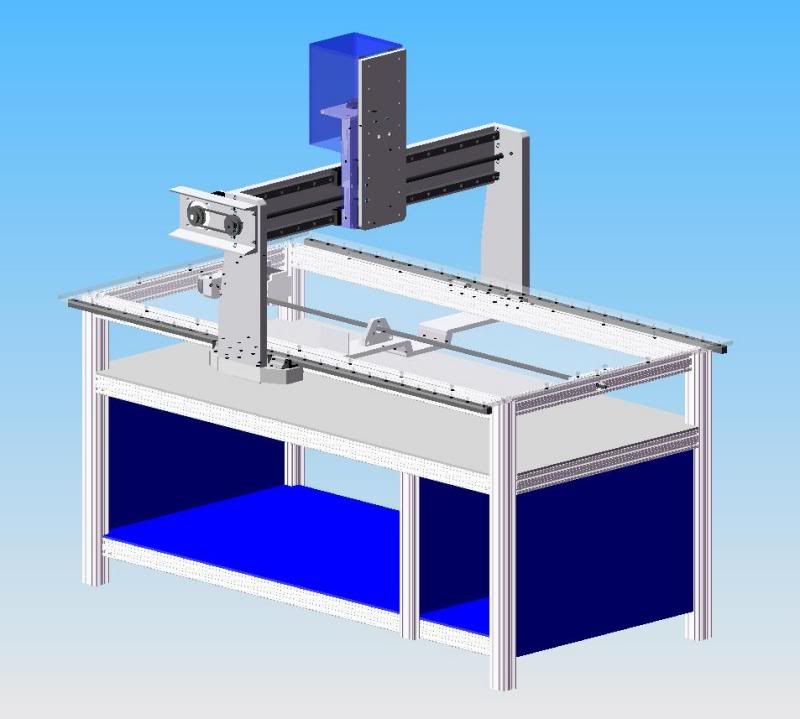

A friend of mine built a small MDF CNC machine and I was amazed at how fast it translated CAD models into reality. He suggested that I make one myself and use it for my business. I took all 5000+ hours of CAD experience and set out on my new mission. LET ME VERY CLEAR: I've never been a fan of MDF as a rigid construction material, but Aluminum :idea:. I found CNCZone and spent the next 1.5 years reading every thread I could and evaluating every design on here (thanks guys, this site is amazing). Some I liked, some I did not (i.e. not enough cutting area, MDF as the primary construction material, uses a wood router as spindle, etc). I really liked the Data-cut design, so I used it as a base and made quite a few modifications to suit my needs. Here's the base model (figure 4). These are all of the parts that require machining so I does not include bellows, spindle, enclosure, etc. The only problem was I had zero machining experience. My I first thought was to farm out the work; couldn't be that expensive right? WRONG, the lowest bid was $9,000+ for everything. I thought there had to be another way....

About My Shop

I started a thread (CLICK HERE) and bought a Seig X3 two years ago for the sole purpose of making the CNC router (figure 5). The X3 is outfitted it with the CNCfusion deluxe zero backlash kit and electronics gathered from Keling Inc. Total cost: ~$3000. Now I will have two machines when the project is over at a fraction of the cost :cheers:. It can hold a +/-0.002 tolerance easily so my machine should come out pretty well.

Results 1 to 20 of 206

-

09-23-2009, 03:44 AM #1

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

All Aluminum, 99% CNC Cut, Composite Router Project

-

09-23-2009, 04:21 AM #2

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

Lets Get Started

I ordered $700 worth of 8020 framing for the base. Almost went with cheap rolling caster wheels until I came upon accesscasters.com/. They have 2" leveling casters for $16.00/ea (figure 1)! Bought fours and machined brackets to mount them to the frame (figure 2). These were my first "real (0.001 tolerance, machine correctly set up, and good production quality code)" parts in almost two years of CNC :cheers:. The base is done (figure 3)!

-

09-23-2009, 04:25 AM #3

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Looks good.

I hope those casters lock tightly. You don't want the machine walking around on it's own.

Gerry

You don't want the machine walking around on it's own.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

09-23-2009, 04:39 AM #4

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

The X Axis

Machine Cutting Area

X Axis: 60"

Y Axis: 35"

Z Axis: 07"

Motion Transfer Method

- NEMA 34 634oz Stepper Motors

- 5/8in Acme Screws with DumpsterCNC Anti backlash nuts

Most of the router will be built from cast aluminum tooling plate. It ground flat to 0.003in on both sides and very stable. Where I live the temperature can vary widely in one day 106F in morning and 60F at night. The prototype router was built with regular 6061 aluminum and all the parts warped within a year .

.

Here's a shot of the 20mm guide block carriers (figure 1). Here is a shot of them and the guide rails mounted on the X Axis table top (figure 2). I had to farm out the table top due to it being so large. It was also CNC cut and thus VERY expensive. Also got the bearing brackets done (figures 3 & 4). All that remains is to get the acme screw machined.

-

09-23-2009, 04:42 AM #5

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

-

09-23-2009, 02:47 PM #6

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 58

Kelvin,

This is way too cool...like that airplane frame you have. What did you use Solidworks?

Too late for me now to change my major...35 years as a EE, but I am having fun with my new found diy home shop. Good tip about those casters i will pick up a few, have a mill. router and lathe that I would like to setup on casters.

Keep up the good work.

groov

-

09-23-2009, 03:47 PM #7

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

-

09-24-2009, 06:37 AM #8

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

X Axis 70% Complete

All of the machining is done for the X Axis. Tooling plate is an awesome material to work with. Machining those angle blocks without an angle vise wasn't easy (figure 1). Here's a shot of everything together (figures 2 & 3).

What's Next?

1. Machine the Acme Screw

2. Align Linear Rails

3. Install Igus Chain

-

09-24-2009, 10:00 AM #9

Gold Member

Gold Member

- Join Date

- Feb 2009

- Posts

- 2143

Enough about the machine, let's see some of the planes! ; )

-

09-24-2009, 10:23 AM #10

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 90

Thats a beautiful Aircraft, are you willing to share your designs. Love to fly one like that from my childhood.

Vishnu

-

09-24-2009, 03:02 PM #11

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

Got your pm. Sorry but that design is one of my production models. Once the machine is done, I'll be retooling the mold. You are welcome to buy a kit though. Still not sure about the price yet since cnc will seriously cut down on production time. Should make things a lot cheaper.

-

09-24-2009, 03:57 PM #12

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 58

That is one big ass mic plate ...it must have cost you a fortune!!!

-

09-24-2009, 04:22 PM #13

Member

Member

- Join Date

- Jun 2008

- Posts

- 1082

I'm also curious about that huge plate. Would you be willing to share the details about it (weight, cost, thickness, source, etc.)? That looks like a great platform on which to build a machine and I am interested to know if it's something remotely in the realm of what I'm willing to spend.

-

09-24-2009, 06:31 PM #14

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

-

09-24-2009, 11:33 PM #15

Registered

Registered

- Join Date

- Sep 2009

- Posts

- 96

This machine looks like it will be fantastic! I imagine you'll hit some nice speeds with this kind of precision.

-

09-25-2009, 11:17 AM #16

Member

Member

- Join Date

- Jun 2008

- Posts

- 1082

$700 delivered sounds down right reasonable! $1300 is pretty steep... but well, it looks really good!

-

09-25-2009, 02:01 PM #17

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1268

Any idea how much your going to have tied up in this work of art when you are finished? First class job!

Billbillyjack

Helicopter def. = Bunch of spare parts flying in close formation! USAF 1974 ;>)

-

09-25-2009, 02:48 PM #18

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

-

09-25-2009, 04:25 PM #19

Registered

Registered

- Join Date

- Sep 2009

- Posts

- 96

Hmm 4-6k was far less then I was expecting you to spend

I wish I had a smaller CNC setup right now it would make my machine come out much better. I guess I'll just have to build my machine and then modify it with new parts that I can make with it.

I wish I had a smaller CNC setup right now it would make my machine come out much better. I guess I'll just have to build my machine and then modify it with new parts that I can make with it.

-

09-29-2009, 08:40 AM #20

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

Little Progress

Just got back from a business trip and snuck a few hours in the shop. Made a few parts for the X Axis. They came out very well (+/-0.0005in) :banana:. Here's one (figures 1-3).

A few people have PM'd me about the 3D solidmodel for the router. I never gave it much thought, but would anyone be interested in the 3D solidmodel and 2d drawings for the machine?

Similar Threads

-

two aluminum molds ( for composite parts , simple molds )

By yoi in forum North America RFQ'sReplies: 8Last Post: 01-17-2014, 04:35 PM -

Steele and aluminum first project

By Coogrrr in forum Open Source CNC Machine DesignsReplies: 173Last Post: 08-04-2011, 10:49 PM -

new aluminum project

By Tadas25 in forum DIY CNC Router Table MachinesReplies: 3Last Post: 07-28-2009, 11:20 PM -

aluminum project

By cncsdr in forum Employment OpportunityReplies: 2Last Post: 05-23-2007, 12:06 PM -

composite Polyurethane and Aluminum powder?

By andrew888 in forum MoldmakingReplies: 3Last Post: 05-11-2007, 09:30 PM

Reply With Quote

Reply With Quote