I'm waiting my "little baby" coming home so I think may be a good idea start an Official thread on this machine.

Some guys on this forum bought it and could help newbie like me or others who want to buy.

If not useful delete the post

Official SHM0609 english home page:

http://www.webshcnc.com/english/6096m.asp

Official Excitech picture:

charnwooduk router unboxing post (pictures attached):

http://www.cnczone.com/forums/showpo...postcount=2279

First question:

- what type of maintenance to do when router arrive.

Thanks

Thread: SHM0609 [Official thread]

Results 1 to 20 of 40

-

02-26-2009, 04:12 PM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

SHM0609 [Official thread]

-

03-01-2009, 05:56 PM #2

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 23

Dear friend ,

I have bought from China 3 weeks ago an XYZ 6090 and i am in big trouble still.By the look of the pictures of your baby it MAKE a big difference compare to mine.Can you please advise if it came with NC studio program?Did you have any problem with it?

Looking forward for your reply.

Regards

George

PS:regarding your question of maintenance of the CNC,the most and above all rules from all is clean rails,and sharp tools.

-

03-02-2009, 12:36 PM #3

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

Hi.

First i don't know what's the Ncstudio, but if I correctly understand:

The SHM0609 router is provided by the DSP controller that accept the Gcode.

I found on the forum some posts concerning the NCstudio, hope it help:

http://www.cnczone.com/forums/showthread.php?t=33069

http://cnczone.com/forums/showpost.p...00&postcount=1

the search query:

http://cnczone.com/forums/search.php?searchid=3423784

Could you post the home page factory of your machine?

Thanks for suggestions.

-

03-03-2009, 11:58 AM #4

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 23

Dear friend

thanks for the reply,and the company who sell the router is XYZ-TECH_CNC_Equipment_Co_Ltd.

You see i have bought from the States a new card so i can work with Mach3 instead of the NCstudio wich the router came with.After some reading and searching i came to a STOP with the instalation because the router it has a Hight Frequency inverter to control speed on the motor( DZB brand 200model).

The reason i have ask you for more information is to advise if you can and obviously if possible for you,to send me a photo of your installation regarding the four wires coming out of the bottom of the inverter .In the standard small break out board(BOB)which came with it goes on a fuse with the following order G(red),1,2,3.

What program yours came with?

Is it able to work with Mach or?

Looking forward for your reply

Regards

George

-

03-03-2009, 12:13 PM #5

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

George, my router is on the way (I'm waiting it within 3 weeks) so unfortunately I can't help you.

You can try to send a PM to charnwooduk, a forum member, he got the router 3 weeks ago and may help you.

Take care

Ciao

-

03-05-2009, 02:22 PM #6

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 12

I suspect that this is a different company to Excitech.

I found this picture of the "XYZ-tech" 0609 and it looks like a different machine to the one excitech produce - http://www.ttnet.net/show_html.jsp/c...no/000/type1/A

I am using the DSP to control the machine so cannot advise on how to set-up with mach 3

-

03-05-2009, 02:41 PM #7

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

Yeah, it's not the same router.

Also specifications are different.

Charnwooduk, tell me your impressions after 3 weeks of SHM0609 use.

What type of maintenace you did when you got the router at home?

Thanks

Ciao

-

03-05-2009, 06:55 PM #8

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 12

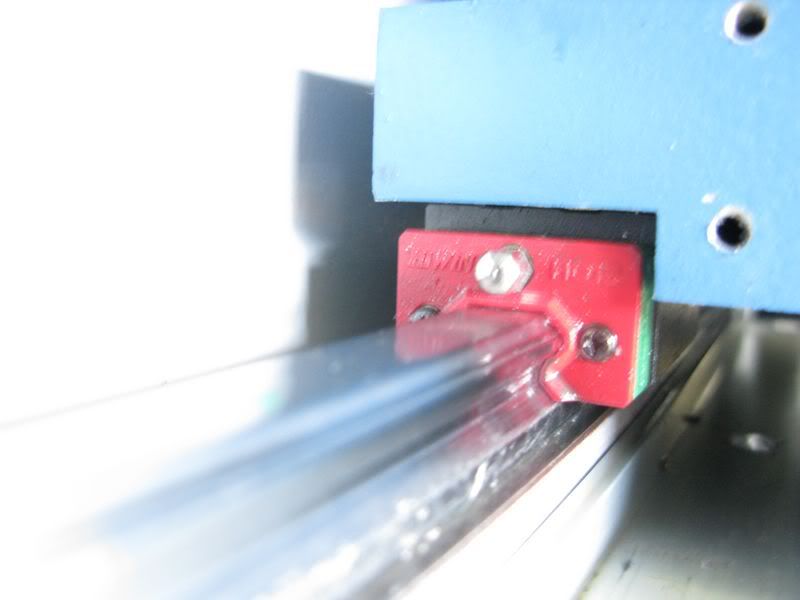

For maintainance, i simply removed the dust covers for the rails, wiped everything clean and applied lots of grease to the lead&ball screws and wiped oil over the rails.

Also the machine bed was not quite flat, but as it is a hard plastic "foam", it is easy to mill flat (you can see the pattern left in my pictures.. bed is now perfectly flat.

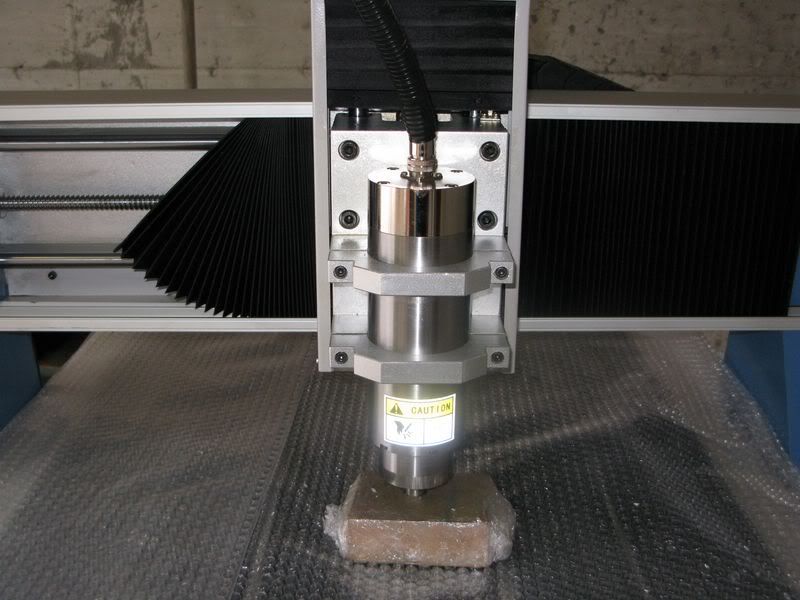

I also adjusted the position of the spindle as it was mounted too low. The new position gives the full 120mm of travel (this is a two minute job to complete)

I am using the VFD control panel to operate the spindle as it did not seem 100% reliable from the DSP, although I have not spent time to investigate the issue (set function F00 to 4 and F01 to 0 on the VFD to enable this)

Made a vacuum hold down table for cutting some small rohacell parts (see pictures).

90% of my machine time is cutting 3D, as I am not worried about saving time, my 2D routing is not at very agressive depths.

-

03-09-2009, 11:38 AM #9

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

Thanks.

Did you used a gcode to flat the bed or manually via the USB controller?

-

04-17-2009, 07:23 AM #10

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

Router received.

As first impression it's a good costruction.

Here some pictures:

The box:

The tool box:

Front Panel with the delta and, on the right, the cord for the zero tool:

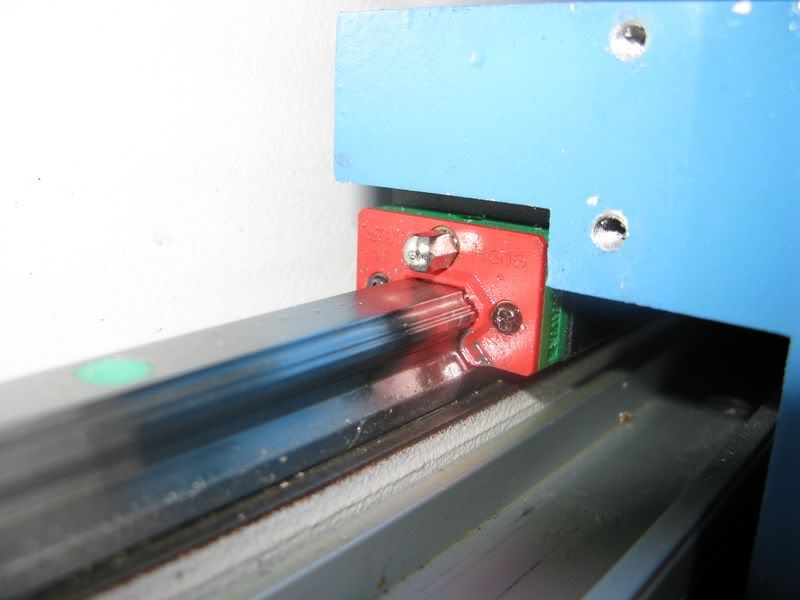

The Hiwin rail guide:

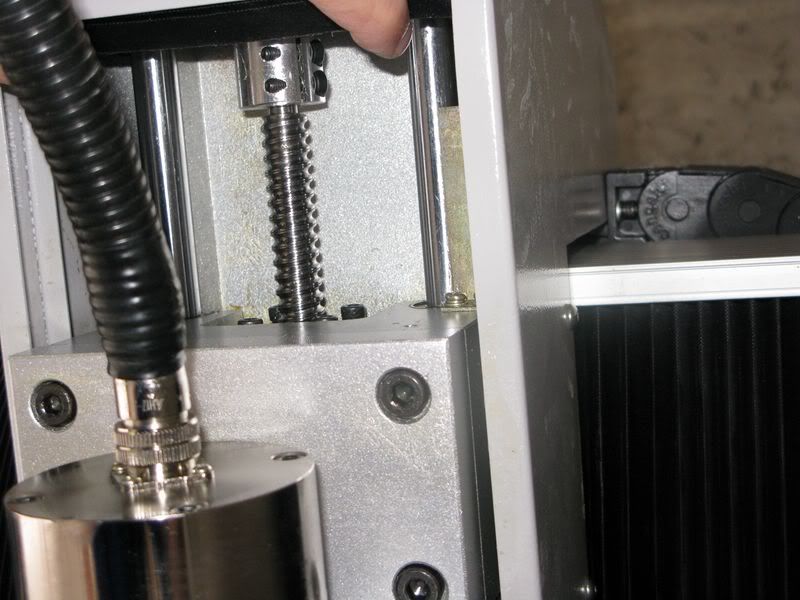

The ball screw:

The plaque:

As wrote the costruction is overall good.

The only thing is that you can't use a transpallet to lift up the router, there are no solid beams at the bottom.

I already emailed this to Taney and he prompt reply me that this will be improved.

I will post others pictures next days.

Ciao

-

04-20-2009, 02:03 PM #11

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

The zero tool:

The X axis:

The spindle:

The Z axis:

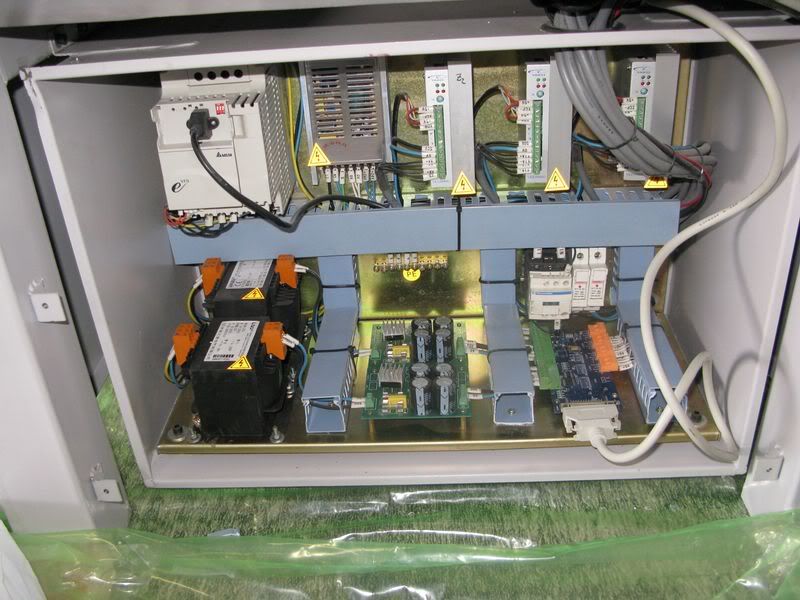

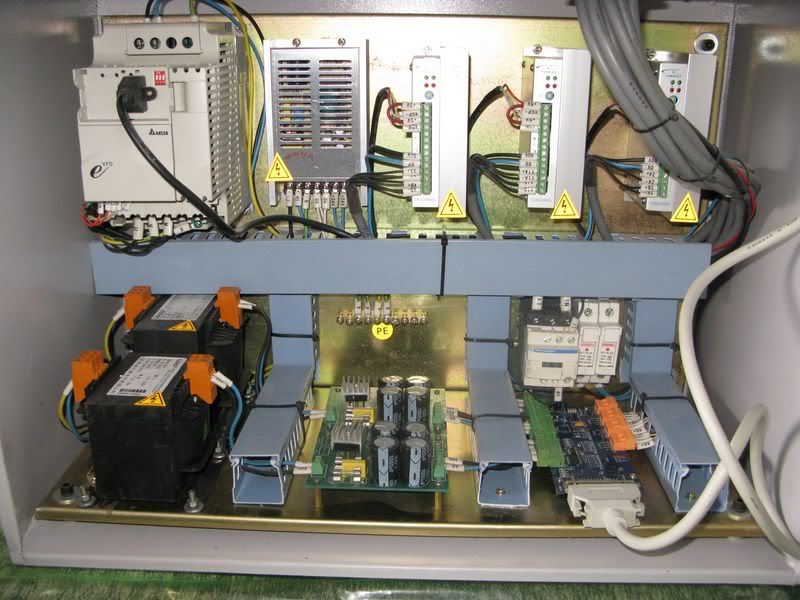

The electronic:

Back side:

-

04-20-2009, 03:16 PM #12

Gold Member

Gold Member

- Join Date

- Nov 2007

- Posts

- 2466

i have seen a few of these machines and your photos are great and show what one should expect!! excellent post

jimJames McGrew CAMaster 508 ATC

www.mcgrewwoodwork.com http://dropc.am/p/EJaKyl

-

04-21-2009, 08:11 AM #13

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

Thanks Jim!

Yours compliments are very welcome.

Hope to help some one and help Exitech to improove this router.

Some little things to do (like, not little, remove it from the wood base) and start working.

Cleaned all the rails and the balls screw from the rust protective and grease them.

Next step is to understand the DSP.

-

04-23-2009, 08:03 AM #14

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

Z-zero tool using:

This is what Taney reply me about the Z-zero tool:

First count the thickness of the brass block, input the thickness value of the tool sensor into the DSP handle: MENU--MACHINE SETUP--C.A.D Thickness.

Then press MENU+ON/OFF togehter and relase the two buttons at the same time, the spindle will go down, when the tool tip touch the sensor the spindle will go up, and the system will remember the Z-0 point

I will test it today and let you know.

-

04-23-2009, 08:33 AM #15

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

Firts test

This is a video of first test I did, a file included into the DSP:

[ame="http://www.youtube.com/watch?v=0GMJ52gN8E4"]YouTube - Test[/ame]

machine is working high at 5.49 m/min, homing X and Y at 6 m/min.

-

05-18-2009, 08:34 AM #16

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

Machining the first 3d file I did:

[ame="http://www.youtube.com/watch?v=3ozamzqC9VY"]YouTube - Primo lavoro[/ame]

mm 110 x 110

Tools used:

1- end mill mm 3

2- ball nose mm 1.5

3- end mill mm 3

Cheers

-

05-18-2009, 08:46 AM #17

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

To pump grease into the Hiwin block nipple you have to use this tool with a "zerch" cap:

-

05-18-2009, 09:41 AM #18

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

Sensational thread!!

Sensational thread!!

Congratulations woodworker.

The photos are excellent

The youtube videos are great.

Commentary also excellent.

You are operating your machine like a seasoned professional already.

Great work.

Look forward to seeing more!

Rocket.

-

05-18-2009, 10:28 AM #19

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 52

Thanks rocket, you are very welcome

-

06-22-2009, 06:06 PM #20

Registered

Registered

- Join Date

- May 2009

- Posts

- 5

As anybody managed it yet to control the spindle speed via the DSP?

Regards, ray

Similar Threads

-

SHM0609 lubrication

By carveit in forum Excitech routersReplies: 10Last Post: 02-27-2010, 12:33 PM -

[Emc-users] EMC2 on Ubuntu 8.04 Hardy Heron LTS - official announcement

By samco in forum LinuxCNC (formerly EMC2)Replies: 7Last Post: 09-02-2009, 11:32 AM -

Cap and Trade to be Official Policy

By dynosor in forum Environmental / Alternate EnergyReplies: 2Last Post: 03-26-2009, 05:29 AM -

SHM0609 to buy and users experience

By yksur in forum Excitech routersReplies: 8Last Post: 02-10-2009, 02:56 PM -

TEKdrive Servo Drive Official Release Today!!

By Kookaburra in forum News AnnouncementsReplies: 0Last Post: 05-14-2006, 11:32 PM

Reply With Quote

Reply With Quote