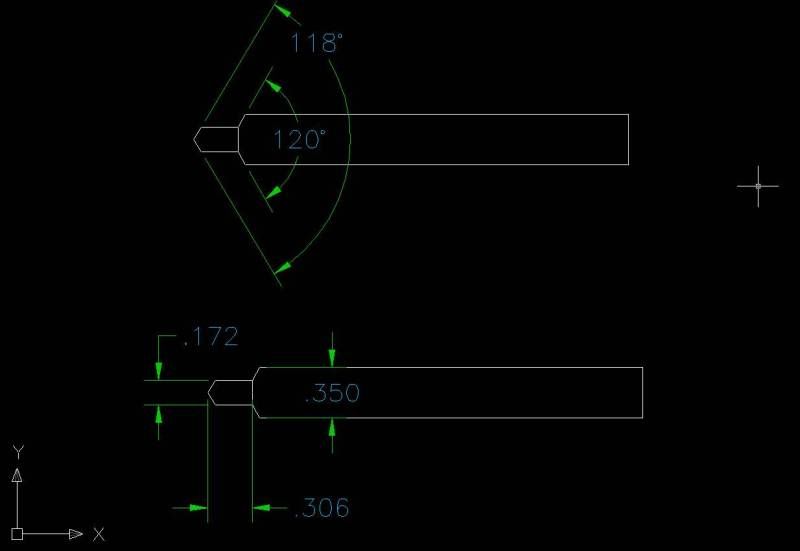

Im using a custom ground step drill pictured below to drill and countersink a blind hole in aluminum

Its been giving me trouble from the get go

Im feeding to +.100 of final depth,

retract to clearance, rapid back to +.120 final depth,

then feed to final depth and dwell a half second

hitting it with M.O.M. oil every 2 seconds

this is coded long-hand

the first "peck" is S7000 F15.

the finish "peck" is S3000 F7.5

the upper diameter of the c-sink is .300

I was breaking these drills left and right till I got to these feeds and speeds

now the problem is the taps are breaking

these taps were doing over 2000 holes each and never broke, now two have snapped in as many days

the tap breaks off in one hole on the frame, but the remaining un-tapped holes all look fine,

the tap is an oversized HSS 8-32 spiral flute for helicoil inserts

I had no idea these blind holes would be so problematic

I use a similar step drill on another frame with thru holes and it just keeps going and going...

I decrease the speed on the last feed move because the countersink doesn't like high rpm

I think the fact that the countersink and the drill tip are both cutting the last .100 simultaneously at low rpm is causing the trouble

Anybody got some insight on this combined operation for thru holes?

a better tool maybe?

a coding tweak?

thanks in advance

Kenny

Thread: blind hole, custom drill

Results 1 to 8 of 8

-

12-09-2008, 02:58 PM #1

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 247

blind hole, custom drill

-

12-09-2008, 04:58 PM #2

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 464

Use a thread mill for the blind holes.Or tap half way down and then chase it manually.

Stefan Vendin

-

12-09-2008, 05:43 PM #3

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1389

I've used many form drills and form endmills.

what I have found is that pecking doesnt work as well as its just like drilling through a pilot hole and the form tool will bounce around.

if you can't drill one shot I am guesing the tool was made incorrectly

however its been working so what I would do since you are pecking is make sure your first peck is short enough so it doesnt touch the bigger dia. only the pilot, then way on your final peck it recenters/ and gets tool pressure on the pilot and then cuts the the big dia.

if yuor using a canned cycle did you happan to change the start distance? for example if you had a start of Z0.1 and changed it to Z0.150 where the peck stops for its next peck will be different.

Remember always calculate the peck from were your retract point is not from zero

as a example

like with .100 peck depths

if you started at Z0.1 and goto Z-0.350

your first peck is at Z0.0

Z-0.1

Z-0.2

Z-0.3

Z-0.350

if your retract starts at 0.150

your first peck is

Z0.050

Z-0.05

Z-0.150

Z-0.250

Z-0.350

I have had guys/including myself change the z start after the job gets running to save time not thinking about were the pecks finish on each peck. Form tools this can be very important.

As far as tapping blind holes use a roll tap they are stronger and don't make chips they are just as good as thread milling but less expensive.

I assume your doing this on a cnc mill as you said spindle speeds of 7k.

also how are you holding the drill and the tap? drill chucks dont work good for step drills. use a quality collet holder

-

12-09-2008, 08:37 PM #4

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 247

thanks delw for taking the time to help out,

the drills major diameter is .325 so I cant hold it in a collet,

Im chucking it for now

the machine is Haas GR408

I coded the drill cycle long-hand as a subroutine and the 1st peck does stop

before the major diameter engages

-

12-09-2008, 09:03 PM #5

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1389

the final peck does start before it makes contact with the major dia.?

I would advice buying the er coller tools,it will make all the differnce in the world and its worth every penny.

I dont even drill with a drill chuck anymore unless its less than .062 dia. I have noticed a huge tool life increase and far less chatter and walking problem.

Fake Edit

your running a haas router never saw one till just now. pretty damn cool machine. It does have a ct 40 taper tool holders you should be able to get a tool holder with a er series collet from us shop tools pretty quick.

http://www.usshoptools.com/current_y...r%20collet.pdf

It may also be a rigidity issue at high speed and you might have to slow the rpm way up to keep it from chatternig if you continue to us a drill chuck.

Delw

-

12-09-2008, 10:10 PM #6

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 247

I have ER25 holder and collets, but none that hold .325 tool

this is a custom tool, I can get the next batch made at .375 major diameter, same price, won't cause any problems and I got a 3/8 collet

here's what my sub looks like,

the drill tip is .306 long so the major diameter doesnt touch till the 2nd peck

N1000

G0 Z.1 S7000

G1 Z-.3 F15.

G0 Z.1 S3000

G0 Z-.28

G1 Z-.4 F7.5

G4 P.5

G0 Z.1

M99

-

12-09-2008, 10:37 PM #7

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1389

the 5/16 (will open)or 11/32 (will close) collet will work, these collets close nice and evenly, you won't need to order them if you have them, you will be real surprised at the results.

I use them all the time and they are very accurate

-

12-09-2008, 10:40 PM #8

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1389

ooops just saw the pause statement in your program, dump it(especially with a drill chuck) you can also get the same result if you just feed slower for the last .005 and wont notice a rise in part time. for some reseon a drill chuck when it doesnt have pressure on it will chatter like heck.

if its one of those parts that has to have a pause I usually feed it slower like by half or less for .005. dont know why but its something I have done and it gives a nice finish.

N1000

G0 Z.1 S7000

G1 Z-.3 F15.

G0 Z.1 S3000

G0 Z-.28

G1 Z-.395 F7.5

G1 Z-.4 F2.0

G0 Z.1

M99

Similar Threads

-

Looking for small "blind hole"? clamps

By rkremser in forum MetalWork DiscussionReplies: 4Last Post: 10-08-2008, 12:23 AM -

NEWBIE HELP>> How do you input a drill hole or extrude a hole that is..

By l u k e in forum SolidworksReplies: 9Last Post: 02-11-2008, 05:54 PM -

Spade Drill Does Work in Aluminum; Big Hole Boring on Drill Press.

By Geof in forum MetalWork DiscussionReplies: 47Last Post: 02-01-2008, 08:32 PM -

drill hole

By larry53 in forum MetalWork DiscussionReplies: 8Last Post: 05-20-2006, 12:50 AM -

Drill hole

By avengine in forum Community Club HouseReplies: 0Last Post: 04-30-2006, 01:33 AM

Reply With Quote

Reply With Quote