I guess I will start a thread on this one. It really doesn't deserve a build log. It's not really a conversion. I just stuck some motors on it. The only thing I had to modify was the gear cover for the Z axis motor.

The brackets just clamp onto the stock parts. I got the plans for these little brackets from JFettig. http://www.jfettigmachines.com/

He sells the kits, but he also lets you download the drawings and plans. Thanks a bunch.

Saved me some time. I had to modify the drawings just a little. I had draw the bracket for the Y axis or tailstock for drilling. I used basically the same style clamp though. I milled a recess so it slipped over the ts casting about .25". They are all nice and solid. I locktited some studs in the clamp parts and then just used lock nuts.

everything is left standard on the lathe. It is tuned up a little, but if I am going to use it much, it will need some mods. Firstly and perhaps most critical is the lead screw. My half nut is cast iron. It works fine but should wear fairly fast.

There are also no bearing or bushings at all in it. I did drill an oiler hole in the carrier under the spindle.

I will install a ball screw or at least an acme screw and dumpster nut here.

It has just a little back lash. I will tune it up a little more. I had it loose enough to easily move by hand. Under motor control, it can be a little tighter on the carriage.

I am figuring out just how to do the code on a lathe. It is different than a mill, but I am actually using the setup for a mill.

I am running some drilling cycles in Sheetcam and swap the letter in the code to Y. That drills my stock full length first.

I then use the turn wizards in Mach Turn. I add this code under the peck drilling and it is able to do just what I wanted.

I will eventually make a bigger lathe or perhaps convert a 9/20.

I know guys have done a lot with these little lathes, I want the versatility of a larger more accurate one if I am going to put a lot of money in it.

Someone may get a good buy on a yellow 7/12 eventually.

Enough for now I think.

Here are a few pics.

Thanks for the image help guys.

Thread: 7/12 stock to cnc

Results 1 to 9 of 9

-

02-03-2008, 04:28 AM #1

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

7/12 stock to cnc

Lee

-

02-03-2008, 03:39 PM #2

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

A little more about whats under the hood.

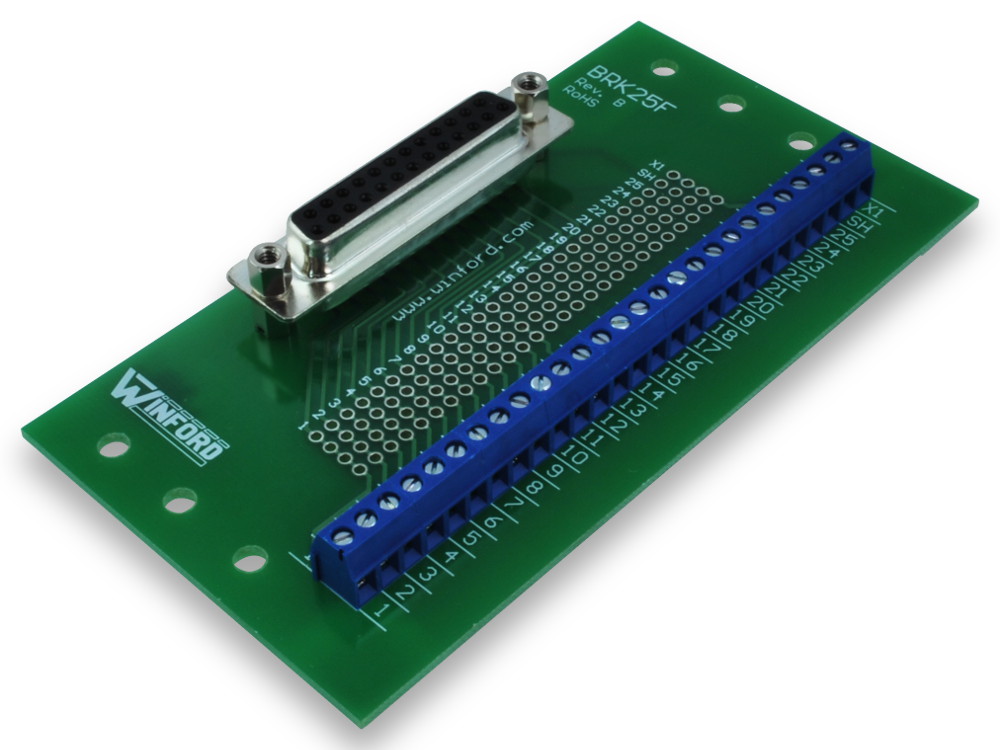

I am using 3 gecko 201's, a 48VDC 7.3 A Keling power supply, a Sony 5 VDC 2000 miliamp laptop battery charger for the common 5 VDC on the Gecko's. I'm using a stand Winford BOB. No frills. I am using a switching PS for the 12 VDC I needed to run the fans in the case.

I made one good computer out of several I had. I had to take the ram out of one and the PS out of another, but it's nice and stable. It's running XP optimized for Mach. Below is an older photo of that control box.

My motor step settings (in case I loose them) are 50,800 steps in X.

33866.66666 steps in Y or on the tailstock.

32,000 for the Z lead screw.

The lead screw runs good @ 45 IPM and 20 IPM on the other two. They can go higher, but I am scared of loosing steps. Crashing on a lathe seems like it would be much more undesirable than on a mill.

This is all with just the standard screws. Made my own straight steel motor couplings. The tailstock seems to have a little wiggle when rapiding, but it still seems to drill nicely centered holes without a pilot or center drill.

The other two are smooth running.

I initially had my rapids set pretty high on the Z with a decent matching accel. Well, it popped the half nut then. 45 IPM with an accel. of 16 is what I'm using now and it doesn't pop the half nut. Anyone know of a way to tighten the half nuts up? I haven't studied it yet.

Lee

Lee

-

02-04-2008, 03:14 AM #3

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

I did manage to get a video uploaded.

It was a lot of fun learning how to use the teach wizard in Mach 3. I used it for the X and Z moves and used a peck drill cycle in Sheetcam and then just globally swaped the Z for Y in an HTML editor.

The same drill cycle should work for any drill I use in brass. I'll have to slow it down considerably in steel.

I am going to adjust my feedrates a little higher too. This was the second editing of the code. Third time should be a charm.

[ame="http://www.youtube.com/watch?v=mdO5aleyDVg"]http://www.youtube.com/watch?v=mdO5aleyDVg[/ame]Lee

-

02-05-2008, 02:34 PM #4

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

I was having some movement trouble in the lathe. Carriage, cross slide and compound.

I had replaced the original carriage blocks because the front one was busted from the factory. Really cheap pot metal is what that looked like.

I used some fairly thin brass bars. 1/8" thick and about 5/8" wide I think. These are working okay, but I think I want something a little thicker. I will get some better brass bar.

I relapped the dovetails and gib strips and readjusted those. I retightened the backlash on the screws. It is now tighter than I like when manual mode. It isn't too tight to cause stepper stall, but is tight enough that I don't see any movement when I wiggle the parts.

I bought the A2Z QCTP and it appears now to be the weak link. I can actually see it flexing a bit. I had to adjust my code to get the first and last bushings to come out within .003 of each other. That is now well within my tolerances.

I never use the compound slide anyway, so I am thinking it may be time to just put a tooling plate on there in it's place. I'm sure I have seen pictures of guys machines that have done that, but if anyone has a link or picture, that would be great.

I removed the rack and carriage gears. I put a rubber screw cover over the lead screw.

I also installed a rubber shield over the control switches to keep swarf out.

I moved my tailstock closer to the chuck so I don't have as much material sticking out. Smoother cuts like that anyway. I also doubled the feed speeds from whats on the video.

Now I get a lot of chips slinging way out in the shop. I don't mind the chips. It the flying part that ain't safe.

I will fab up a hinged chip guard for it at some point.

More photo's when I have at least that part done.

I also want to cover the motors. These have holes in the rear of the motor where there could be a shaft running through. Easy enough to blow chips into the motor through those.

I will mount some fine screen over them first, then cover.Lee

-

07-29-2010, 04:01 PM #5

nice conversion dear leeway,

i am surprised to see the video, such a small lathe. But i want to know which one is giving better results? your home made lathe or this converted one?

(i know the answer if i think about the rapids, but how about tolerances?)

and why don't you use gang tooling in this converted lathe too? get rid of that y axis tail stock.

jasminder singhIt is better to die for something than to live for nothing.

-

08-30-2010, 12:26 AM #6

Registered

Registered

- Join Date

- Nov 2008

- Posts

- 73

Leeway, i wonder how is this lathe for cutting steel? I have chanced upon an ongoing job to run some small parts and am thinking about doing just what you did and buy a cheap little lathe throw some motors on it and use it to make some $ to get or build something better. But this job requires turning and boring steel, is this little machine up to the task?

Thanks,

Jim

-

08-30-2010, 12:19 PM #7

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

The lathe itself will cut steel without too much trouble. I have turned ball screws on these a few times now. I have to say that it is a much better manual lathe as is than a cnc lathe. I found it to be underpowered, flexy, lots of backlash and required too much adjustment with the stock parts to have much precision. Pretty much defeats the cnc benefits, though I did use it a while on my brass bushings. They did not require that kind of precision.

These issues are handled well when in manual mode.

They were the reasons that I decided to build my own though rather than throw money at this one to make it better.

If I was going to buy a lathe and just add motors, I would buy one a little bigger than the 7 xx's. I would also add the motors and keep the manual wheels on the ends of the motors.

Even though I have my shop build cnc machine here, a manual lathe is a very nice thing to have. I have my original manual lathe setup close to the cnc lathe and find I use it often for one off things.

No question which is the better machine of the two I cnc'ed.

I can really turn some stuff on my shop made machine. The Z axis now has a 1200 oz nema 34 motor. The X still has the 570 oz 23. Spindle setup is still like it shows in my other thread. The video I posted of it is only about 1/3rd speed of what it cuts today. Backlash on it is less than .001 due to the double nuts. It works exactly how I wanted it to.

Hope that helps, guys. Thanks.

Link to my shop built lathe.

http://www.cnczone.com/forums/showthread.php?t=59421Lee

-

11-15-2012, 09:44 PM #8

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 0

Question

If you dont mind me asking how much did it end up costing you to build this lathe and also how much time did you invest into the build.

Thanks

-

11-15-2012, 10:52 PM #9

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

It probably took 20 hours or so to machine the parts and install them.

Probably around $500 above the lathe cost for the drives and BOB and motors.

You can get by a whole lot cheaper there.

Probably buy all that on Ebay for $150.00.

Maybe even less.Lee

Similar Threads

-

Stock Origin

By stang5197 in forum MastercamReplies: 4Last Post: 03-13-2007, 05:36 PM -

3d stock model

By camtd in forum EdgeCamReplies: 2Last Post: 10-20-2006, 05:36 AM -

Turning Hex Stock

By osmqc in forum Haas MillsReplies: 2Last Post: 03-01-2006, 03:00 PM -

Boards in stock?

By slamman in forum Hobbycnc (Products)Replies: 5Last Post: 02-11-2006, 11:45 AM -

head stock and tail stock chucks

By mocnc in forum DIY CNC Router Table MachinesReplies: 3Last Post: 10-20-2004, 03:16 AM

Reply With Quote

Reply With Quote