Folks, Hi again... it has been quite a while since you last heard from me, but i've recently started a new CNC project..

Introducing!..

the "HBM C1 Lathe", i believe this is one of the many Proxxon Lathe Copies made in China, but.. this is a quite decent machine..

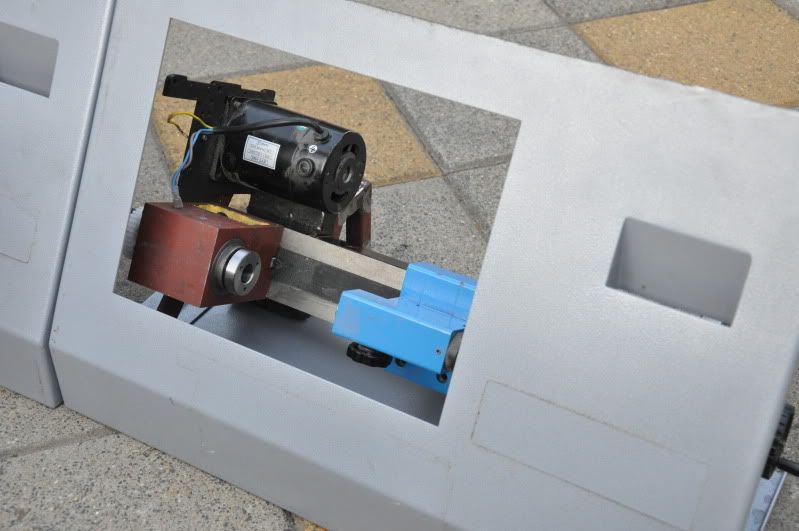

So!.. for starters, i dismantled the entire machine, and carried all the parts upstairs to my "office"

where i started taking measurements, and drawing all the parts in Alibre Design

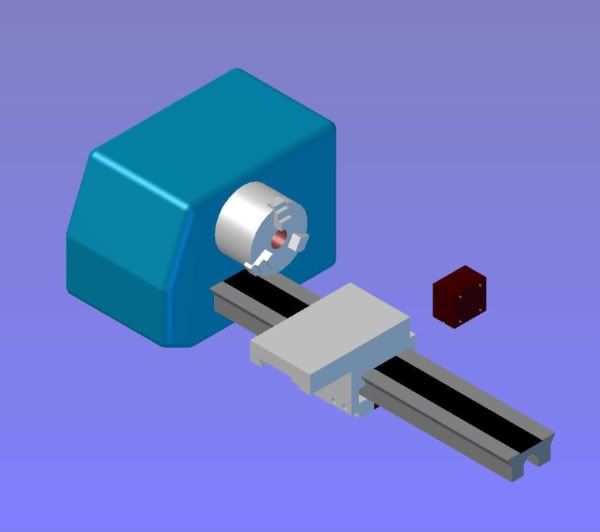

I started out designing, aiming at a "standard Lathe, with 2 steppers attached, running on Ballscrews, and USBCNC for the control..

But then!.. things started to go haywire, in a pleasant manner..

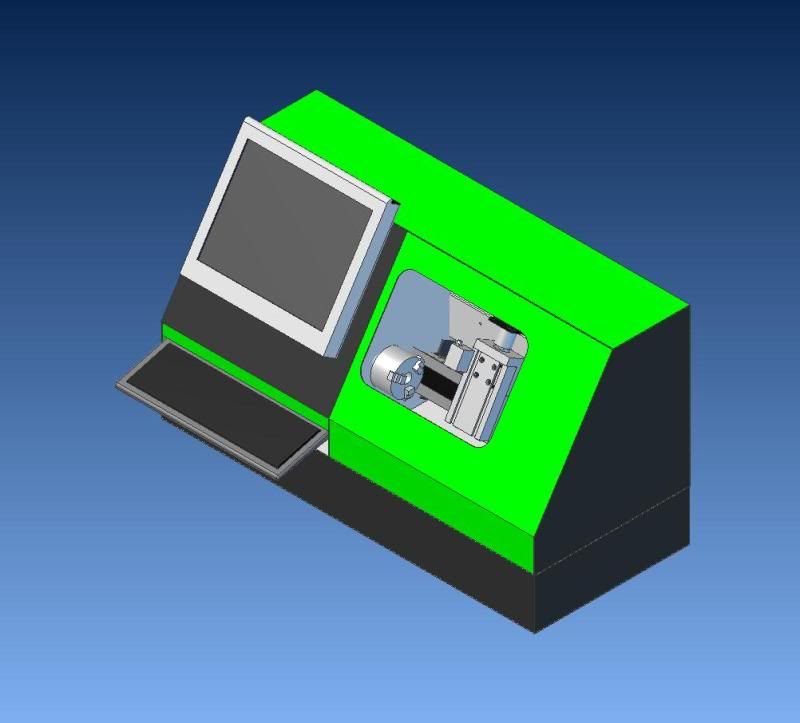

I managed to get hold of a 15" Touchscreen which had originally been mounted in a cigarette vending machine..and when i saw the casings of those machines, i started picturing my lathe inside one of those casings.. hmmm

so. i bought a Touchscreen, and got 2 casings free to go with it..

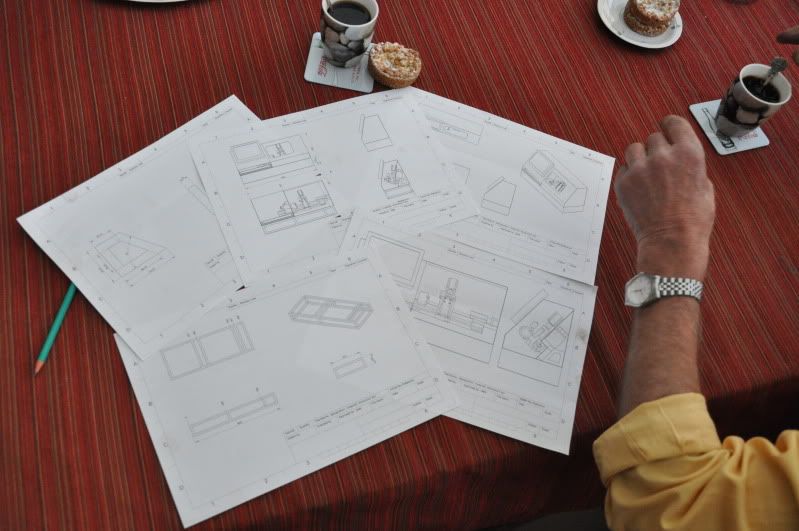

so i took some measurements, with the help of my father, deciding how to mount the lathe inside those steel cabinets..

and then... i was talking to a friend on MSN, dicussing CNC machines, since he also has a CNC mill, and he wants to CNC a Lathe also..

and he mentioned he had a 1.8 Kilowatt motor lying around, with a VFD already dialed in and ready to run.

So after some negotiations i got myself a 1.8 kw motor to put on my lathe instead of the 0.15 Kw DC motor it originally has..

So, i had to change the design slightly, but that was done in a jiffy.

Ok.. On to Work.. To the BatCave!.. erhmm.. the garden shed that is..

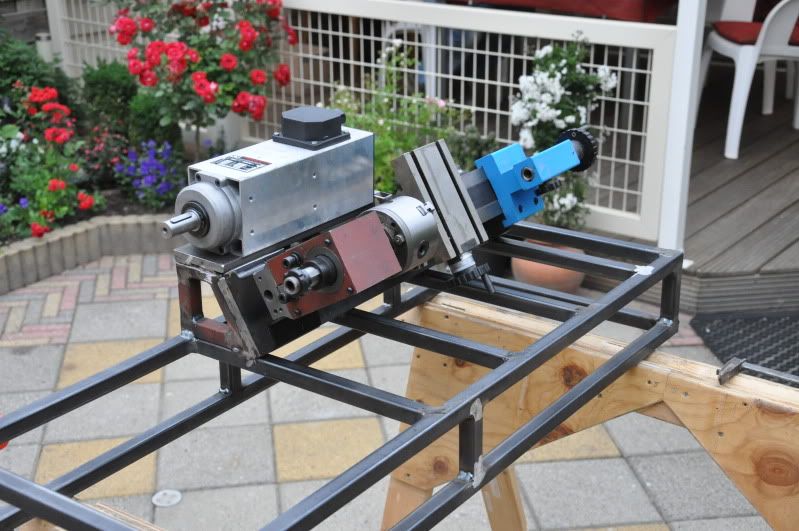

Welding the brackets to "slant-mount" the lathe..

So i got 4 of these.. and i also cut the cabinets to pieces.. in order to fit around the lathe..

while drinking Coffee, my father and i further discussed some details

The next day i went to the local Construction company, only to find out they were not very willing to cut some steel for me, and even receive a fair amount of dosh for it.. well .. have it your way.. dumb-ass-numbnuts..

so, on i went to another company, i never before thougt of, just two blocks away from my home, but they didn't have the required steel in stock, so, i hopped in my car once more, to another company, in another village, just 5 minutes by car.. ( this is the netherlands after all ), and they were able to supply me with the desired steel, some 20x20 Square tube, and 2 pieces of flat bar..

which, off course i welded into a frame the very next day.

and i think something went wrong here..

Results 1 to 20 of 62

Hybrid View

-

06-06-2011, 07:36 PM #1

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Kabaalstra is back, CNC-ing a Small Slantbed lathe

-

06-06-2011, 07:52 PM #2

Registered

Registered

- Join Date

- May 2004

- Posts

- 402

Mobius Loops

A bit of photoshop in that last picture I think!!

Andrew Mawson

East Sussex, UK

-

06-06-2011, 09:50 PM #3

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

What's the story on the Canadian flag welding hat?

Gerry

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-06-2011, 11:01 PM #4

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Yeah.. i admit.. i did "Gimp" the image of the welded frame.. (flame2)i don't use Photoshop.. i use Gimp..

the story of the canadian Welding Cap?.. well to be honest, i was given the choice, the salesrep of our welding equipment had two caps with him, one in blue with all kinds of flashy colours on it, and one with canadian flags..just thougt it looked nicer..

did some more welding..

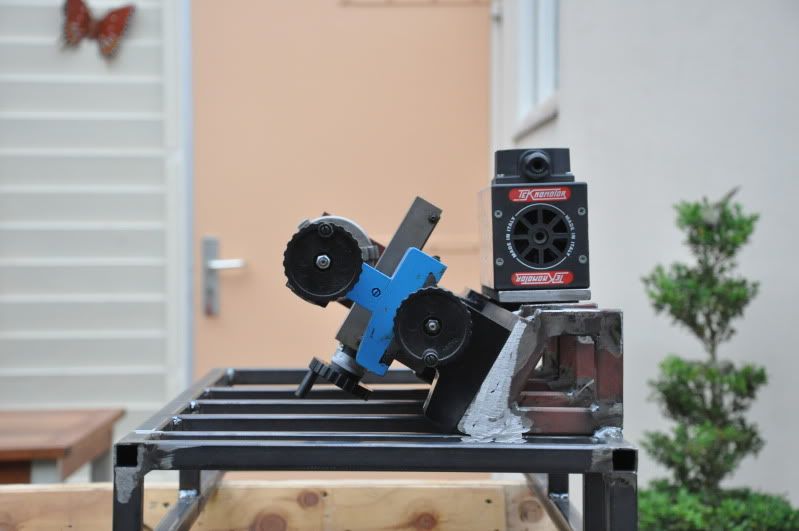

and after welding that lot, i put the slant-brackets on top..

and i drilled the mountingplate for the lathe bed, and the motorsupport plate, and welded them also..

and i did another "dry-fit"

screwing all kinds of parts together..

and this is what it should become in the near future.

-

06-07-2011, 04:02 AM #5

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

-

06-07-2011, 11:02 AM #6

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Yep.. that "escherish picture was just to play a trick on you guys.. :cheers:

a Do-it-yourselfer?.. well i think that's about the understatement of the year if you've seen my other project..

http://www.cnczone.com/forums/vertic...wn_design.html

Enjoy reading...

'bout taste.. well.. i've seen some documentaries about Canada.. think it's a nice place to live.. i do have 3 Uncles living in Canada, one is a cattlefarmer, and two are AppleFarmers, so whenever you eat an apple, or drink applejuice, it might just be... :wave:

Today i will spend time on final design of the ball screws, and couplers for the steppermotors.. and maybe i'll find time to design a toolchanger as well

-

06-08-2011, 09:28 PM #7

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 24

Hello Arie,

nice design of a small Budget cnc Lathe.

Greetings Rene

-

06-06-2011, 11:06 PM #8

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

very cool!

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-06-2011, 11:40 PM #9

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Thanks!..

the empty space under the screen will be used for a control panel with X, and Z, Jog buttons, 2 handwheels, Spindlespeed override and Feed Override knobs, as well as a Start and stop button, and an Emergency stop.

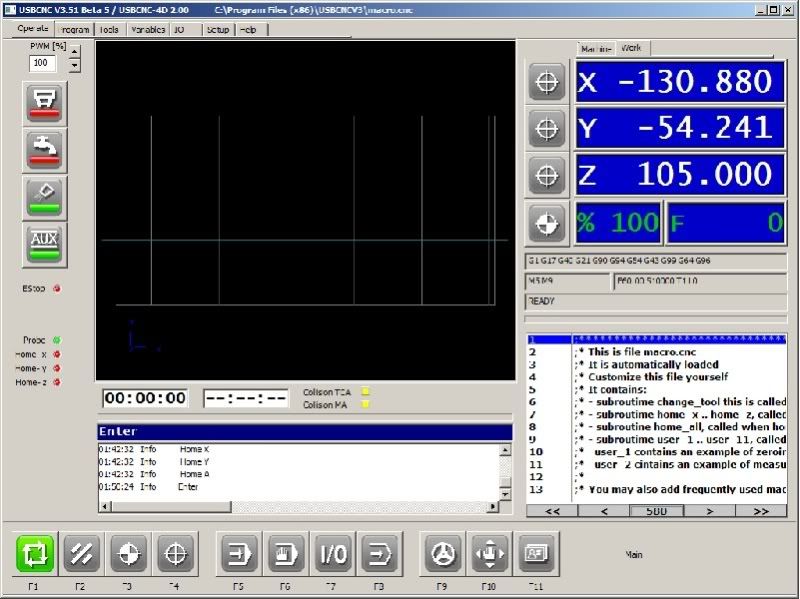

as mentioned before, i'm gonna use USBCNC to Control the machine, with the new CPU 5 Board.

and i will use a Pokeys 55 IO board to connect the different switches..

i recently discovered that one can use a rotary encoder on a Pokeys 55 to control 2 keyboard shortcuts, so Feed+ and Feed- will be programmed on the pokeys on the A and B channel of a Rotary Encoder, and the same will be done for the Spindle override..

Furthermore i will be writing some macro's in USBCNC for inside and outside turning, Facing, and threading, as wel as taper-turing and rounding, to enable "shopfloor programming" of most parts..

I also will be writing an IDE to write Visual G++ Code programs to enable Dialog-programming of parts with multiple cycles.. (part-programs) like on a Fagor 8055 Control..

I already did so for my CNC VMC, wich i can program like its a Heidenhain control..

Since i've learnt a lot of VB.Net programming i'm also planning on building an IDE for making dialog programs, like the wizzards in Mach, but then enabling the programmer to put multiple cycles in a program, i will have to build an "intermediate machine language" for that, but it will enable programmers to "shopfloorprogram" all kinds of machines from one IDE, no matter what control you are running.. just build your program in the intermediate language, and compile it for your machine.. it will then generate the code suitable for your machine..

(since most Hobby CNC controls have the NIST G_Code interpreter, i will be able to generate G-Code ready for Mach, EMC Planet CNC-USB and USBCNC.)

But!.. Since USBCNC has a library file to store frequently used subroutines in, i will be able to run the intermediate language directly on my machine..since the intermediate language will be built upon the Visual G++ language i already have developped for my machine..

-

06-07-2011, 03:55 AM #10

Registered

Registered

- Join Date

- May 2010

- Posts

- 48

-

11-29-2011, 02:08 PM #11

Member

Member

- Join Date

- Sep 2005

- Posts

- 1195

When will u start to teach us on usbcnc, its kinda interesting? Its been so long time now....

-

11-29-2011, 07:54 PM #12

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Well.. then i guess i'd have to open a topic here..

since i started with CNC, USBCNC was still very small, and unknown, at the moment, even machine manufacturers are building they're machines with USBCNC, and those are not just manufactureres in the Netherlands, but throughout Europe..

At the moment i'm also writing special programs for a portugese manufacturer, for a machine that wil make standard parts in different sizes..

What can i say about USBCNC,, it is very different from Mach.. as i posted earlier on this forum, i HATE mach.. don't like the looks of it, don't want to spend weeks on programming something that looks better to my taste, but is still the same old software.. because... that's all what mach is.. software..

USBCNC however is a CONTROLLER.. it uses a CPU board that is connected by means of an USB cable ( hence the name) or an Ethernet Connection ( latest model )

USBCNC doesn't have top cope with the crappy timing of the LPT port, it has its own internal timer on the CPU, and a BUFFER.. so even if the USB or Ethernet Communication is somewhat slow, nevermind.. the buffer will "iron out" al those glitches.., a one-stop solution for Smooth machine movement..

the GUI is designed by a professional Toolmaker ( me ) based on the logical layout of a Heidenhain control, but since most controls operate in basically the same manner, it may just as well look like a modern Fanuc, Siemens or even Fagor..

Fact is, Softkeys for all the functions.. don't need a mouse to operate it..don't want mice in the workshop after all.. ( and.. in all my life.. i've never seen a Bridgeport with a mouse attached.. )

When you don't like the standard button images.. those can be changed.. this is my own buttonset..

the most beautiful feature of USBCNC is the "Macro.cnc"File, an G-code file with all the routines for toolchanging, tool measurement, and some other things already in it..

there's a menu with "user buttons" linked to user subs in the macro.cnc file, in these subs, you can program whatever you want to use frequently, so a "standard program is available at the push of a button..

and.. since the latest releases, USBCNC features a new function to one of the most versatile commands..

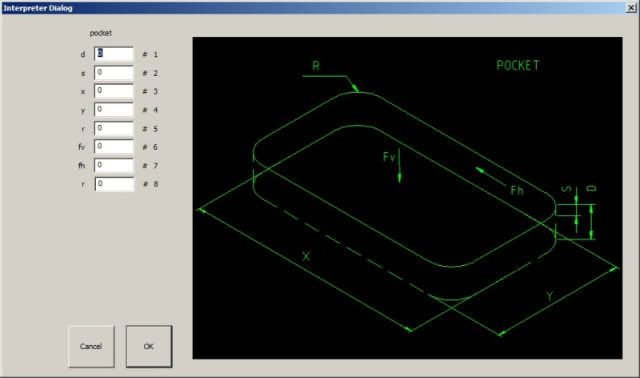

the DLGMSG ( DiaLoGMeSsaGe ) will now look for an image to display, making clear what value is for wich function..

Let me dig up a picture of that.. :stickpoke

I've drawn a picture of a rectangular pocket.. and i've threwn some dimensions into it. this basically shows you what value to put where, to get a pocket of a certain size..

When you put the code for this parametric pocket in one of the user subs, you can push the matching butten ( for wich you can also make a custom icon as i stated before) and get your "Cycle", key in the numbers hit Enter, and off you go..

For companies with some standard products, this enabels them to produce flexible, without the need of a fast programmer or CAM software.. just write a parametric program once.. store it in Macro.CNC, and that's about all there's to it..

-

12-03-2011, 09:09 PM #13

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 9

USBCNC

been planning my first CNC build for the last couple of months and have been very interested in USBCNC compared to the other stuff out there...

BUT! it seems currently more for milling than for turning. when (if ever) will it be capable of controlling a bar fed gang tool lathe with full C axis milling capability? or maybe it already can and i'm just not seeing it?

-

12-03-2011, 10:11 PM #14

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Well.. Bar feed?.. that's just sending a signal to the feeder.. can do.. Bar Feeders should have their own control... can do i'd say..

C-Axis milling?.. dunno.. one should have an indexable spindle for that, right?..i know Bert Eding is working on that..

Gangtool?.. should not be that hard.. just tell the machine what tool is where..

there's this Macro.CNC file which you can stuff with whatever code you can dream of..

-

12-04-2011, 08:04 AM #15

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 9

the bar feed needs the collet opened and then an input to tell the controller that the bar has been fed so it can close the collet. also, when reaching the end of a bar the feeder needs to tell the machine to move the bar stop back so it can eject the unused bar end and feed a new bar. i'm sure the controller is capable of this by setting up aux inputs and outputs but would be nice if they were named.

gang tooling is no problem, G54-59.3 take care of that.

a C axis with full interpolation and not just indexing is the big hurdle. if that's what's being worked on then this controller is going to end up very nice indeed.

-

12-04-2011, 11:24 AM #16

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Give or take a few parameters, a barfeeder isn't any more complicated than a toolchanger on a mill..

such a device is also dependent on the status of some sensors, to see if the toolchange was performed..

G54-G59.3 will do for Gang tooling i think.. but.. you could also use parameters instead, so you can use more than 9 tools..

setting up an array with toolpositions is quite easy..

-

12-04-2011, 04:45 PM #17

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 4

Super werk (Nice job), Arie. Ga zo door, kerel. Ik blijf je het volgen.

-

12-04-2011, 10:15 PM #18

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 9

still going to be a while before i start anything so in the mean time i guess i'll play around with the software a bit to try and understand it all....all this CNC stuff is very new to me.

all i really know at this stage is that i absolutely must have a full C axis to do the parts i need.

thanks for listening...

-

12-05-2011, 12:46 AM #19

Member

Member

- Join Date

- Sep 2005

- Posts

- 1195

Arie,

You mention about the use of Eding CNC - PC based CNC control, what motor and driver (AC or DC servo) will be used on your lathe? Is that Eding CNC boards replaced BOB, just connect driver and Eding CNC board. Can we use mach3 on this eding board cnc? Thanks.

-

12-05-2011, 01:17 AM #20

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Basic layout of my control will be:

a Mini ITX Intel 945 PC board 1.6 GHz

connected to the USBCNC interfaceboard

an 80 Volts powersupply to power the motors

and some other stuff like limitswitches.

the USBCNC board does not replace a BOB, with USBCNC you don't need one..

start,stop and limitswitches can be connected to the board, as wel as the drivers by means of a flatcable.

you can't run Mach through the USBCNC Board, and to be honest, why would you even consider that, since USBCNC is far superior over the outdated Mach software.. USBCNC isn't like mach, it is in fact a controller, the timing is not done by the PC ( with windows interfering all the time) it is done by the board, by its onboard CPU

If you check out Eding CNC - PC based CNC control and take a peek in the manuals in the download section,youll find all the answers..

Similar Threads

-

Thread small in back

By jeffm in forum Daewoo/DoosanReplies: 13Last Post: 02-07-2013, 05:47 PM -

has anyone tried a slantbed lathe??

By marx911 in forum Uncategorised MetalWorking MachinesReplies: 8Last Post: 06-21-2012, 05:28 AM -

Small screw with back and forth motion

By breathe in forum Maintenance DIY DiscussionReplies: 3Last Post: 10-29-2010, 05:49 PM -

possible build: slantbed lathe

By bramvh in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 10-26-2010, 01:44 AM -

Slantbed Taig CNC Lathe

By sprinter in forum Taig Mills / LathesReplies: 4Last Post: 02-22-2009, 05:12 AM

Reply With Quote

Reply With Quote