Been a member for a while but never posted here cause I'm not "converted". Hope that doesn't prevent me from being welcome here.

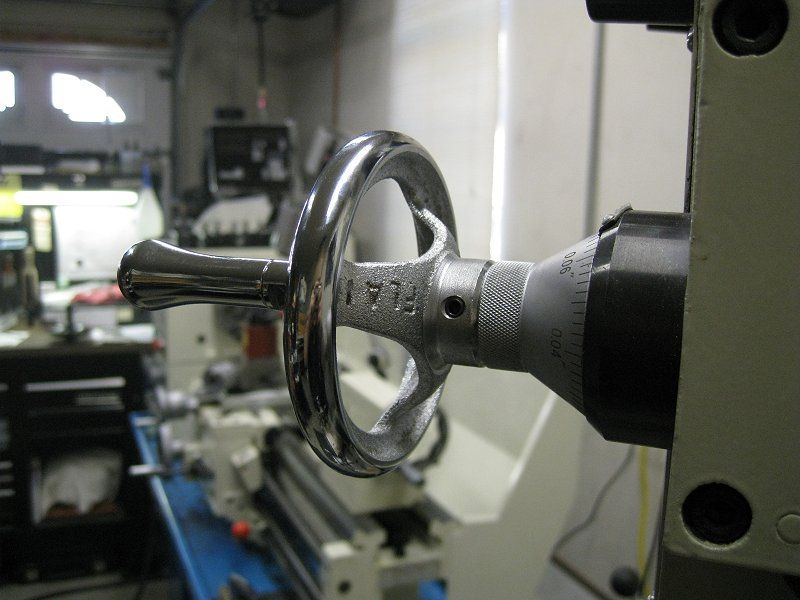

Well since I still turn handwheels, I'll start off with my cast iron handwheels. I hated those stock phenolic hand wheels. They're made by Flair/ Chang Iron Taiwan. I used 6" & 4" wheels.

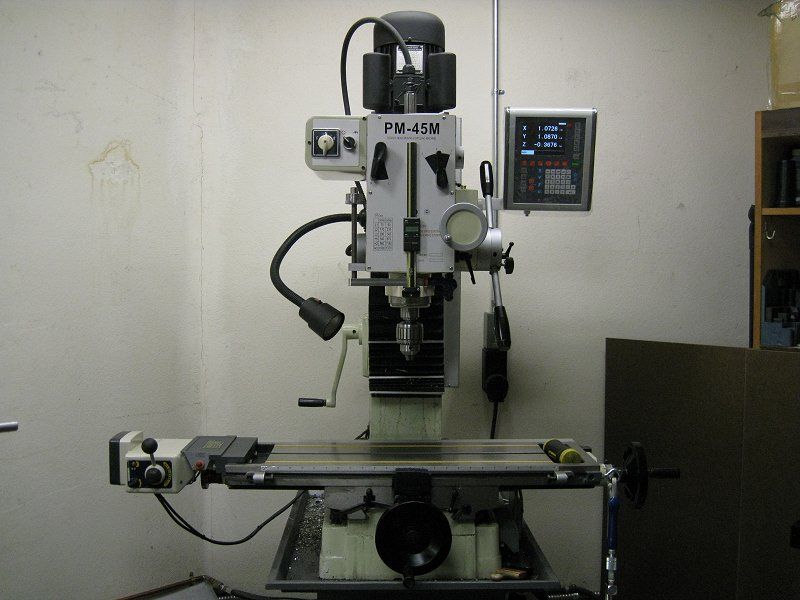

Stock:

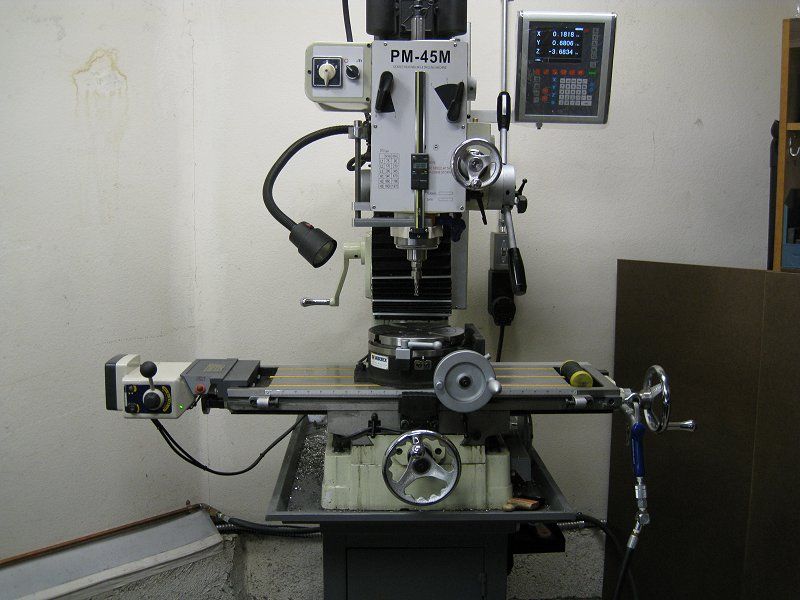

New handwheels (I replaced the X, Y, quill, & handle for the Z).

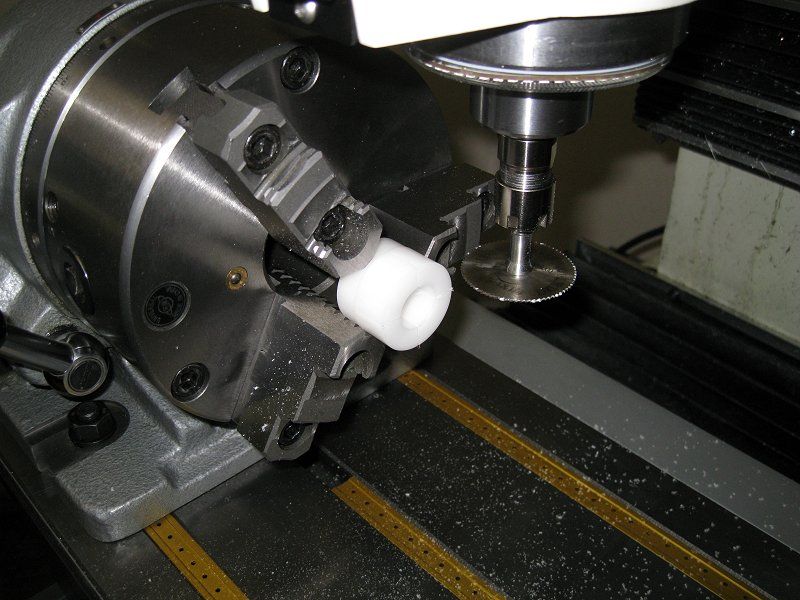

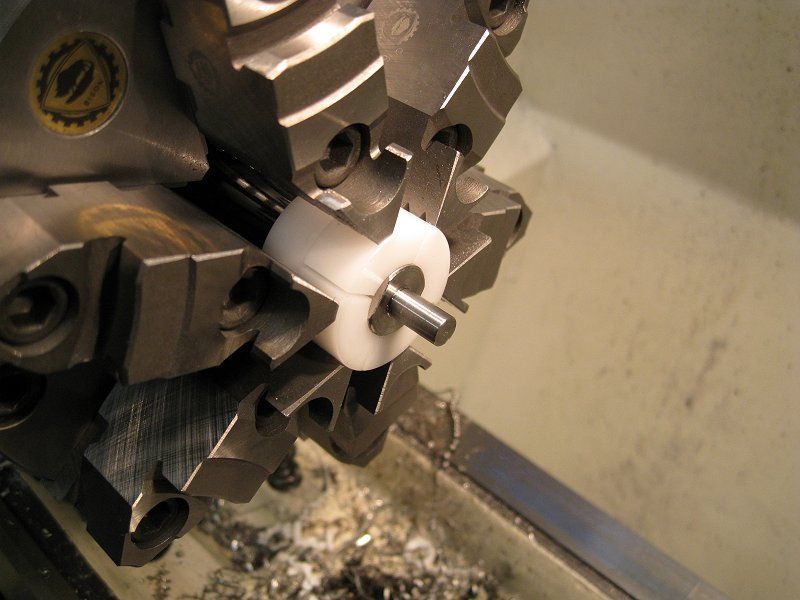

WIP pics:

The revolving handles I used are 3/8-16" thread. My Z handle (head) is metric M10 so I turned down the threads, pressed on a sleeve, & single pointed the metric threads. Had to make a collet to hold the handle.

I made the M10 thread longer than the 3/8" thread.

Installed.

Next was the quill fine feed handwheel. It did not come prethreaded for the handle so I had to drill & tap the 1/4-20 threads. Bored the center to fit my quill feed shaft & drilled & tapped for the set screw.

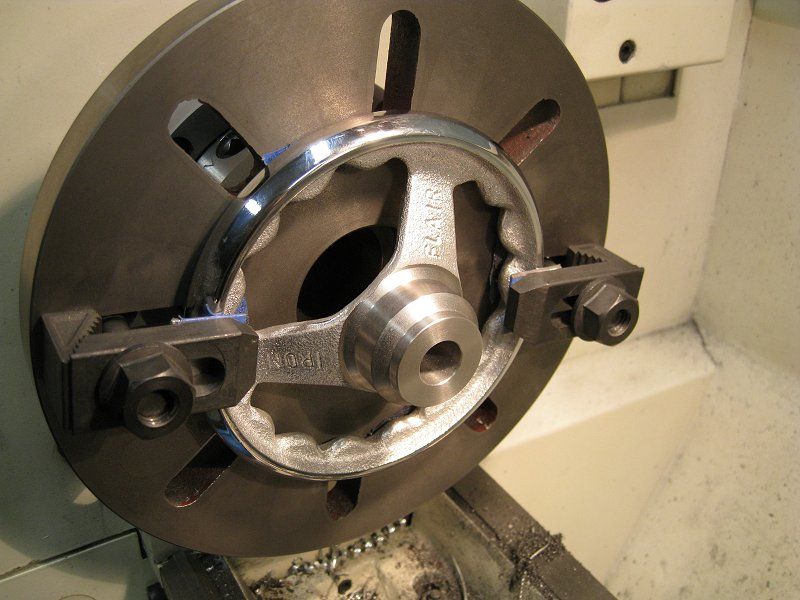

Next was to machine the X & Y handwheels. The new cast iron handwheels had a much larger hub dia than my stock ones so I machined them down. Also had to bore the center. Unmachined as received on the left.

Machined the drive to match.

Finally, mounted.

Thread: Some of My PM45M-PDF Mods

Results 1 to 20 of 24

Threaded View

-

02-28-2015, 07:50 AM #1

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 10

Some of My PM45M-PDF Mods

Similar Threads

-

PM45 air and amp knob loose

By LeeWay in forum Hypertherm PlasmaReplies: 3Last Post: 04-15-2013, 10:37 AM -

New PM45 noise?

By tjbaudio in forum Hypertherm PlasmaReplies: 0Last Post: 07-13-2012, 08:38 PM -

New PM45, arc problem ?

By mcv300 in forum Hypertherm PlasmaReplies: 0Last Post: 06-20-2012, 10:45 AM -

Is my new Hypertherm PM45 faulty?

By jeepsterjc in forum Hypertherm PlasmaReplies: 2Last Post: 05-01-2012, 06:08 PM -

PM45 Differences ?

By flyinwilly in forum Hypertherm PlasmaReplies: 1Last Post: 09-24-2010, 12:14 PM

Reply With Quote

Reply With Quote