Results 21 to 40 of 56

-

11-16-2014, 04:20 AM #21

Junior Member

Junior Member

- Join Date

- Feb 2014

- Posts

- 197

Re: Mach3 tool table and setting TTS tooling

-

11-17-2014, 03:47 PM #22

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: Mach3 tool table and setting TTS tooling

One thing you can count on. it will be confusing and an error will occur before it is all over.

Personally I would build a touch plate from a piece of proto board or blank circuit board from Radio Shack or similar as Ray mentions. Hook it up to an input pin and use the functions Mach has built in to populate the tool table. Use the tool itself as the probe.A lazy man does it twice.

-

11-17-2014, 03:57 PM #23

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Mach3 tool table and setting TTS tooling

I do it a bit different.

I use a zero tool. Tool1. I have a few tools that are this same length, but everything else is longer. I don't probe anything. I use a digital height gauge and plate. My height gauge does remember it's zero point after you turn it off. When you replace the battery is the only time I have to rezero it. I use tool 1 then. When I break or add a tool, I simply input it into the Mach 3 offsets page.

If I had a gauge block or probe, I might do it differently, but it is pretty flawless for me.Lee

-

11-17-2014, 10:36 PM #24

Registered

Registered

- Join Date

- Jun 2013

- Posts

- 75

Re: Mach3 tool table and setting TTS tooling

If you use that 2" indicator block, doesn't mach3 have an offset for the tool setter in the tool table section. In his case, he would use 2", so he would reference his initial tool like the touch probe, then use the indicator block with the others tool. Putting 2" offset on the tool setter area would calculate his new tools offset based on his reference tool ?

I did something like this a few months back when I tried to build my tool table with the tts . I would get the z with a touch probe off a 1-2-3 block on the 2" side, then change tools and the new tools would go to my 2" mark with the newly added offsets, so I think I had a pretty good handle on that part.

The issue I had was when I generated my g code from 'cambam and ran it with the tool number selected, the tool would use the offset as the zero and start from their instead of starting at "0" as its starting point. So if my probe was 3" long and my tool # 3 was 0.5" long, the offset was -2.5" for tool # 3 compared to my tool probe as my reference tool. When I would run the code using mach3, I would zero using the touch probe and the tool # 3 would start at -2.5" from my already zeroed coordinate instead of going to "0" using the offset to get there.

It can get tricky so when you figure it out, post an update cause my table got screwed up trying to fix my zeroing error, I never went back to figure it out but I would also like to use the tool table to make things a tad quicker and soon add a tool plate for atc set up.

Sent from my XT907 using Tapatalk

-

11-17-2014, 11:44 PM #25

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Mach3 tool table and setting TTS tooling

I don't know if this has caused anyone else issues, but never put tool offsets in the CAM software.

I fully define the tools in the tool tables, but leave out any offsets. When it asks for lead like on drills, I fill that part in as well, but no offsets.

What has happened when I tried that was I would get double offsets in Mach 3 or no offsets at all. Drove me a bit batty for awhile, though that isn't a long trip. Lee

Lee

-

11-18-2014, 12:29 AM #26

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1538

Re: Mach3 tool table and setting TTS tooling

Yes, you have to be careful of CAM applying offsets in gcode generation, and be careful that offsets are actually called when desired (G43). Alax, it's possible G43 was not in the code, so your -2.5" offset wasn't being applied.

7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

11-18-2014, 12:34 AM #27

Registered

Registered

- Join Date

- Jun 2013

- Posts

- 75

Re: Mach3 tool table and setting TTS tooling

I'll have to look into that G43. Thanks guys.

Sent from my XT907 using Tapatalk

-

11-23-2014, 10:27 PM #28

Junior Member

Junior Member

- Join Date

- Feb 2014

- Posts

- 197

Re: Mach3 tool table and setting TTS tooling

So I just started messing with my tool table. This is for a G0704 mill and Mach3 has the normal 3 axis screen, however when I go to build my tool table it is showing me lathe tools on the left column of the table. What the heck! Do I have a setting turned on that I shouldn't?

-

11-23-2014, 10:35 PM #29

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Mach3 tool table and setting TTS tooling

If you are talking about the insert diagram, I never looked at those before. I'm not sure if it changes when you define a tool. I just looked in Mach 3 Turn and it does have some straight tools in the default tool table.

Mach 3 mill seems to only have inserts.Lee

-

11-23-2014, 10:43 PM #30

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Mach3 tool table and setting TTS tooling

I measure everything against my probe tool via a touch plate. That was the easiest thing in my opinion since I don't have any repeatable height tool holders. Dead simple. No need to bother with offsets in the initial setup of the tools. If I had TTS tooling measuring offline would seem to be the easier solution.

-

11-23-2014, 11:11 PM #31

Junior Member

Junior Member

- Join Date

- Feb 2014

- Posts

- 197

Re: Mach3 tool table and setting TTS tooling

I have some TTS tooling and that is why I want to build the table. Thank you both for the reply. I've watched some video's and it seems they all have the same screen I do so...I think I'm good to go.

-

11-23-2014, 11:25 PM #32

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Mach3 tool table and setting TTS tooling

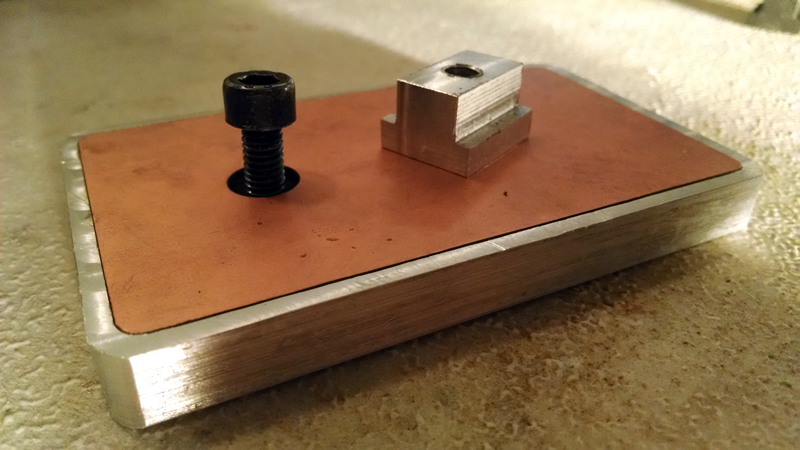

A touchplate setup properly makes things really easy. It took me a while to grasp the tool offset concept but once it clicks you'll wonder why it didn't before. Touch plate doesn't have to be anything fancy. I made mine out of some single sided copper circuit board material an some left over aluminum.

http://diablo.homedns.org/cnc/TCTP.mp4

-

11-24-2014, 12:04 AM #33

Junior Member

Junior Member

- Join Date

- Feb 2014

- Posts

- 197

Re: Mach3 tool table and setting TTS tooling

Well I built the tool table the way I had discussed and it worked as I had thought. When I was done I picked tool 1, put 2" gauge block on a part and referenced my part in Z. Moved Z all the way to home, changed tool number, hit enter and the new tool number offsets were entered. Clicked "Go to Zero" and was on the money!

Now for running a CAM part with tool change call out's. I will not enter any tool offset information in the CAM. What do I do if I have two different drill diameters and one drill chuck? I can pre-enter that data for one but not the other.

-

11-24-2014, 12:09 AM #34

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Mach3 tool table and setting TTS tooling

If you are using multiple bits and the same chuck you'll have to measure them at the time of use I believe. Other wise you'd have a chuck for each drill bit and those would be measured offline. That's where the touch plate is gold. Measuring each tool at the time of use. Great for non-repeatable height tools.

-

11-24-2014, 12:14 AM #35

Junior Member

Junior Member

- Join Date

- Feb 2014

- Posts

- 197

Re: Mach3 tool table and setting TTS tooling

Ok so can I use the tool table and just switch those tools when I need and when the time comes do a touch off to measure just the tools I don't have entered in the Tool Table?

-

11-24-2014, 12:18 AM #36

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Mach3 tool table and setting TTS tooling

Yes. I would put them in the tool table anyway but just measure the offset at time of use.

-

11-24-2014, 12:18 AM #37

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Mach3 tool table and setting TTS tooling

I run all my drills except one in ER collets. I did buy a small keyless chuck and arbor from Tormach, but would not do it again. I use it since I do have it.

If you want to run different drills in a chuck, you can as long as you remember what tool numbers are what sizes. You can buy three sided drill bits. They will chuck up well each time to the same spot on the bit. Give or take .002" or so. I always fudge my bit deeper by more than that though in case I have the lead figured wrong. I use the 135 degree bits from McMaster Carr. That shank type is called slip resistant.

I use the 135 degree bits from McMaster Carr. That shank type is called slip resistant.

McMaster-CarrLee

-

11-24-2014, 12:49 AM #38

Junior Member

Junior Member

- Join Date

- Feb 2014

- Posts

- 197

Re: Mach3 tool table and setting TTS tooling

I have a cheaper 115 piece set right now. Will buy nicer ones as I go and for what I find I use most often. The ER collet is down the road but I do see myself with those soon enough. I could maybe use a sharpie and make a reference mark for the drill's I will use on a part.

-

11-24-2014, 12:54 AM #39

Junior Member

Junior Member

- Join Date

- Feb 2014

- Posts

- 197

Re: Mach3 tool table and setting TTS tooling

That makes a lot of sense and will make it smother I think. I will probably run a part day after tomorrow to see how it goes. I mentioned using a sharpie as a reference and pre-measuring them but I don't know how accurate that will be. I have bad luck breaking drill bits in my work as is! I think I just push them a little too fast and don't use the canned G code cycles. I'm pretty new at all this!

-

11-24-2014, 12:56 AM #40

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Similar Threads

-

Mach3 Mill Profile for Lathe: Tool table referencing

By JOP in forum Mach MillReplies: 6Last Post: 10-08-2012, 05:26 AM -

Mach3 tool table save / print ?

By Scott_M in forum Tormach Personal CNC MillReplies: 7Last Post: 08-03-2010, 12:27 AM -

Tool setting mach3

By kayo in forum Mach Software (ArtSoft software)Replies: 0Last Post: 12-23-2008, 12:20 AM -

Setting up Z axis tool holder height above table

By EL34 in forum DIY CNC Router Table MachinesReplies: 3Last Post: 07-27-2007, 09:28 PM -

Does Mach3 tool diameter override gcode setting?

By WarrenW in forum Mach Software (ArtSoft software)Replies: 1Last Post: 04-27-2006, 02:09 PM

Reply With Quote

Reply With Quote