Hello everyone, I have been working as a machinist (operator) for about 20

years. I have now started work in a small shop where we do a lot of our

programming at the machine. (Fadal) What I need is some good examples

of how to figure out I and J on a outside and inside radius using trig. Why

and when it changes to I- and J- Any good books or online resources

would be great.

Thread: How to trig out I and J ?

Results 1 to 11 of 11

-

09-08-2006, 03:26 AM #1

Registered

Registered

- Join Date

- Aug 2006

- Posts

- 5

How to trig out I and J ?

How to trig out I and J ?

-

09-08-2006, 04:15 AM #2

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1543

Are you asking how to solve for the circle center when you don't know it? The math on this is a bit involved. If you have autocad, or another CAD you can input three points on the circle and it will draw the circle and determine the center.

If you're asking how to get I and J when you have the start point, end point and radius, 9 times out of 10 one of the circle points is exactly on the X or Y axis from the radius. Then you can just subtract. I don't know the trig formula for cases when neither end point lines up, but its not too bad. Again. autocad or another CAD makes this a piece of cake to find the center.

I and J have negative values any time the X or Y distance to center is in the negative direction.

Karl

-

09-08-2006, 11:19 AM #3

Registered

Registered

- Join Date

- Oct 2003

- Posts

- 263

Try this link for an explanation with illustrated examples. Shows up best in Internet Explorer.

http://technology.calumet.purdue.edu...iles/frame.htmSoftware For Metalworking

http://closetolerancesoftware.com

-

09-08-2006, 05:09 PM #4

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 7

Why would you want to use I, J, just use R0+

G1 F5.

X0Y0

G2X.5Y.5R0+.5

THIS WILL CUT A .5 R ,ALL YOU NEED IS A START POINT X0Y0 AND END POINT X.5Y.5 WITH A RAD CALLOUT R0+.5

FADAL WILL LET YOU CALL END POINT AND RAD IF YOU USE R0+" " FOR THE RAD

-

09-09-2006, 09:34 PM #5

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 95

vmc4020,

Here are a few links. I use these textbooks with my students. Both will contain what you are looking for and are a handy shop reference.

http://www.cncci.com/ - Machining Center Programming, Setup, and Operation Self Study Manual

THIRD EDITION

A Guide To Mastering The Use Of CNC Machining Centers

http://www.industrialpress.com/en/Bo...5/Default.aspx

-

09-18-2006, 07:50 AM #6

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 78

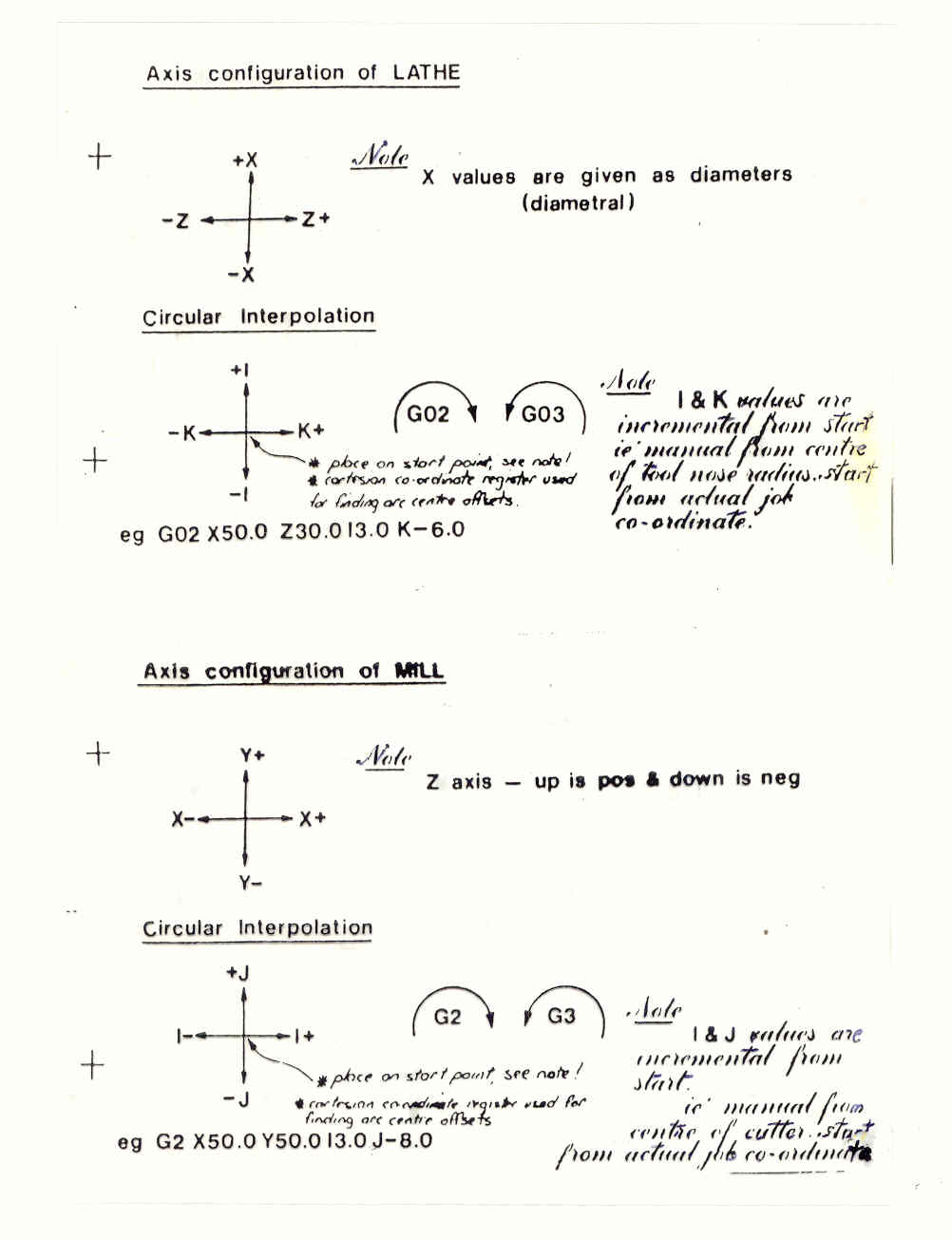

Have a go at this mate

John

-

09-18-2006, 10:44 AM #7

Registered

Registered

- Join Date

- Jun 2003

- Posts

- 205

Trig Software Tool

If you want something that will do it automatically ... without an overpriced CAD package ... try our Trig Kalculator software.

Info at www.KentechInc.com

Kalculator will calculate line-to-line intersecting points as well as line-arc-line points and arc centers from fill-in-the-blank forms ... then plots the results on the screen. It also does the standard right and obtuse triangle calculations ... price is $95.

-

09-19-2006, 02:56 AM #8

Registered

Registered

- Join Date

- Aug 2006

- Posts

- 5

Thanks to everyone for the help and advise. It is not hard when programming a 90 degree radius. Its calculating partial acs that was giving me problems.

All I have is my calculator and my trig book. I need to study up on my geometry also. The example John sent is what I am looking for. It looks more like a lathe job (I and K) but the the same math should apply using I and J

on a mill. (Center of the arc to the center of the cutter.)

-

09-24-2006, 03:54 PM #9

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 251

Try drawing arc on graph paper. Simple sketch will do. Mark center point and then draw right triangles from center of arc to the beggining and end points. Once you have the triangles on the paper you can select the lines which represent the I,J,K values you wnat to find. Use trig to solve for the sides of the triangles.

-

09-29-2006, 03:00 AM #10

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 23

how do i view oldjohn's file? i see the words but is there a diagram too? i would like to learn how to program a radius that blends into an angle on a haas sl40. i run a haas sl40 lathe and a mazak quick turn 30 with a t plus control. we would like to be able to run the same type of parts on these machines, but i am unable to program things like this on the haas. we dont use any programming software.

-

10-11-2006, 02:47 PM #11

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 78

Reply With Quote

Reply With Quote