Time to start a new project.

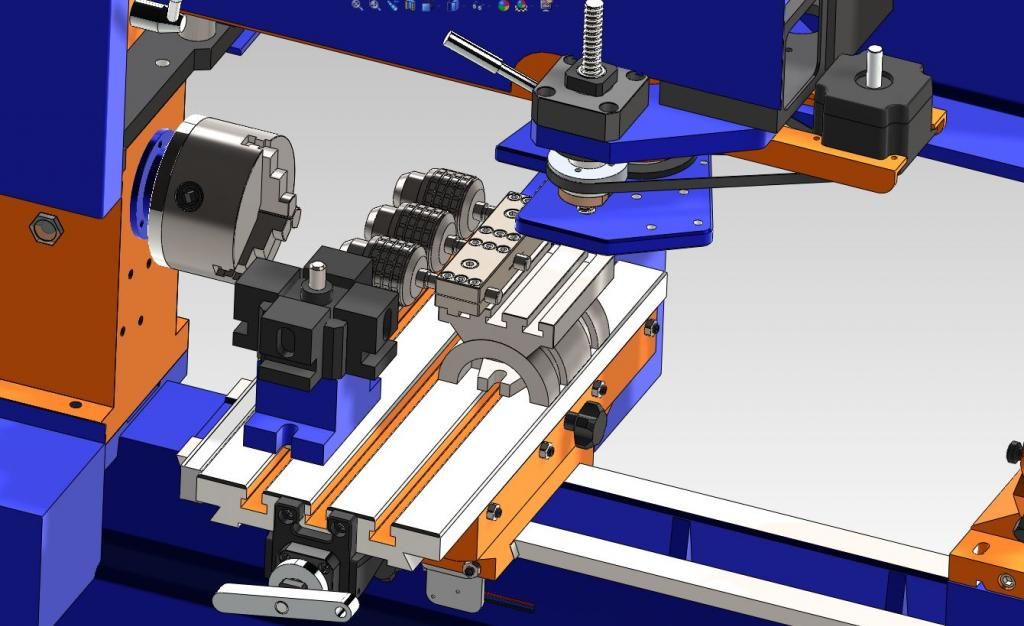

This time it’s for a table mounted chuck gang- to hold drills and centres when I’m turning. I don’t like the tailstock set-up so this is my solution.

Any feedback would be appreciated before I cut metal- any obvious problems?

There is enough room to spin the tool post and enough clearance for the drill bits.

With the gang mounted on the table on the rear most table slot the chuck noses lie at about the right place compared to the tool post.

I based it on a small 4”x 5” angle plate (sits a tad under 3 1/4” (80mm) high).

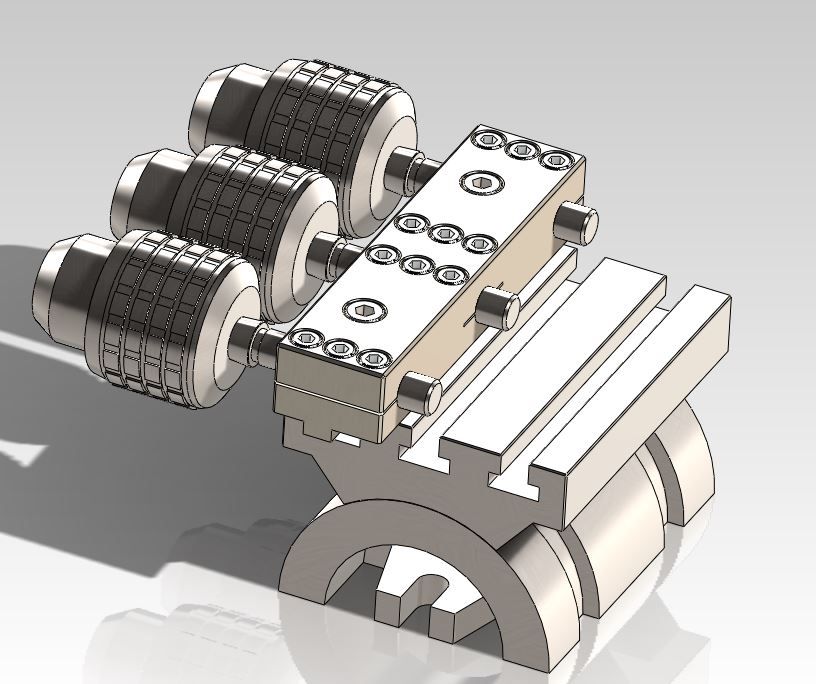

The 3 chucks are 0.8-13mm key driven type with a B16 taper (no arbors).

I picked up three B16 to 12.7mm parallel arbors and a length of 40mm square steel for the mount.

All came in at $150 or so.

First step will be to do some tests to check everything is tight.

I plan to make some T nuts, then mill the steel mount, fix it to the angle plate, finally I’ll bore the three ½” holes using a boring head mounted in the lathe.

Results 1 to 18 of 18

Threaded View

-

09-30-2014, 10:10 PM #1

Registered

Registered

- Join Date

- Aug 2013

- Posts

- 55

Table mounted Chuck Gang for turning.

Similar Threads

-

Table mounted enclosure

By Beezle in forum Tormach Personal CNC MillReplies: 1Last Post: 10-09-2013, 04:13 PM -

Power Draw Bar and Table Mounted Rack Tool Changer?

By David Bord in forum Tormach Personal CNC MillReplies: 5Last Post: 08-12-2010, 03:16 PM -

success! big piece mounted and turning!

By pmurdock in forum Haas LathesReplies: 0Last Post: 08-25-2009, 12:46 AM -

Vertical mounted router table?

By 307startup in forum DIY CNC Router Table MachinesReplies: 15Last Post: 02-09-2007, 04:37 AM -

HF 8x12 MOD (Stud mounted chuck.)

By Dan S in forum Mini LatheReplies: 7Last Post: 04-18-2006, 06:16 PM

Reply With Quote

Reply With Quote