I got done with the mechanical conversion on my PM30 awhile back, and when I started using it, I noticed that the spindle and head were getting REALLY hot. It seemed like it was the spindle bearings as well as the intermediate gears. There was also some noise. I decided to go straight to a belt drive system for the spindle.

First, I replaced the tapered roller bearings with angular contact bearings, and re-greased everything. It ran a lot cooler, although the intermediate gears still had quite a bit of noise.

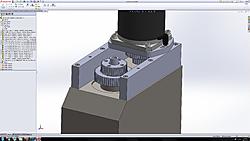

Next, I made some rails, got some pulleys, etc. I'm using a GT2 belt and pulleys from SDP-SI. I just machined off the hubs, bored out the centers, etc to create 2 stacked pulleys. I'm doing a 44:38 ration and a 24:56 ratio for high/low. This should give me around 6500 and 2500 RPM.

Everything went well, but when I went to run it for the first time, it didn't sound very smooth. I messed up the bore on the back pulley, so that's not helping. I will either need to shim it or just redo it from scratch. The other issue is that the belt keeps slipping down. No matter what I do, the belt wants to fall down and ride on top of the casting. If I use the top pulleys, it rides down until it hits the other pulley. Tight or loose, the belt just wants to ride at the very bottom of the pulley until it hits something. Thoughts? Here's the setup in solidworks:

Results 1 to 20 of 36

Threaded View

-

09-12-2014, 07:58 PM #1

Registered

Registered

- Join Date

- Oct 2004

- Posts

- 298

Problems with Belt Drive Conversion

YouTube Channel: https://www.youtube.com/c/RobertCowanDIY

Similar Threads

-

belt drive conversion

By bit pusher in forum Charter Oak Automation Support ForumReplies: 46Last Post: 08-26-2014, 05:36 PM -

Belt Drive Conversion

By RustedOut in forum Charter Oak Automation Support ForumReplies: 78Last Post: 01-15-2013, 07:04 PM -

Can I still get an X1 belt drive conversion?

By Fast01 in forum Benchtop MachinesReplies: 11Last Post: 10-09-2010, 02:21 AM -

X2 belt drive conversion

By port_huon in forum Benchtop MachinesReplies: 7Last Post: 03-11-2009, 09:29 AM -

Belt drive conversion for X3?

By phantomcow2 in forum Benchtop MachinesReplies: 2Last Post: 07-17-2007, 12:31 AM

Reply With Quote

Reply With Quote