As for the Y axis.

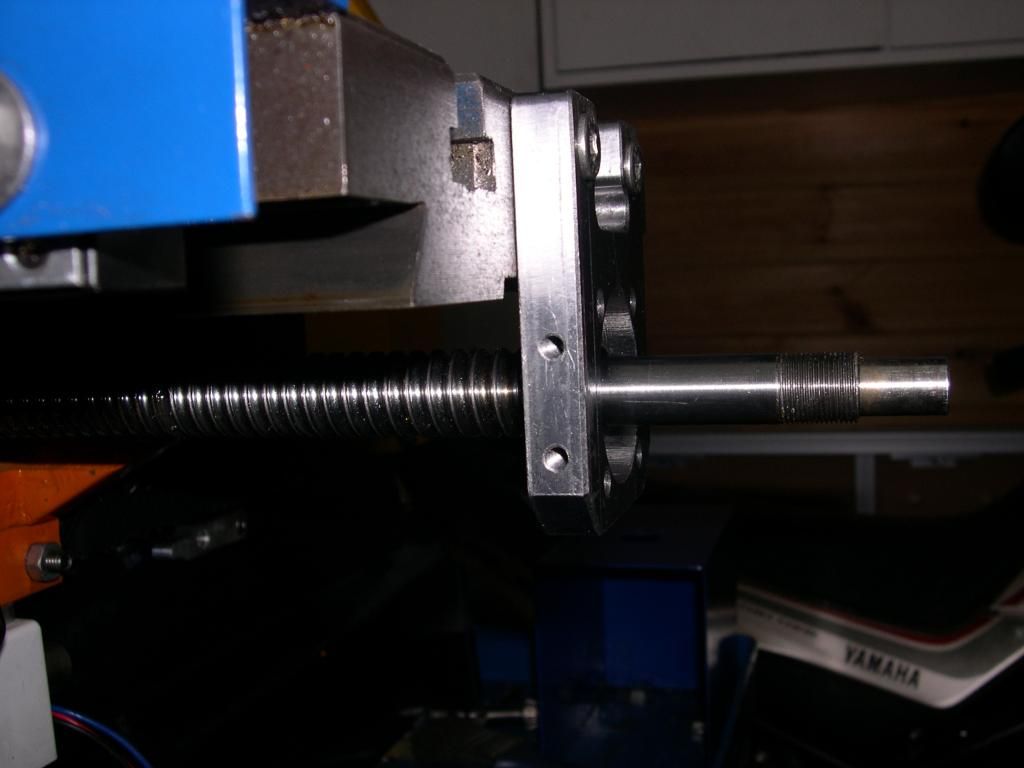

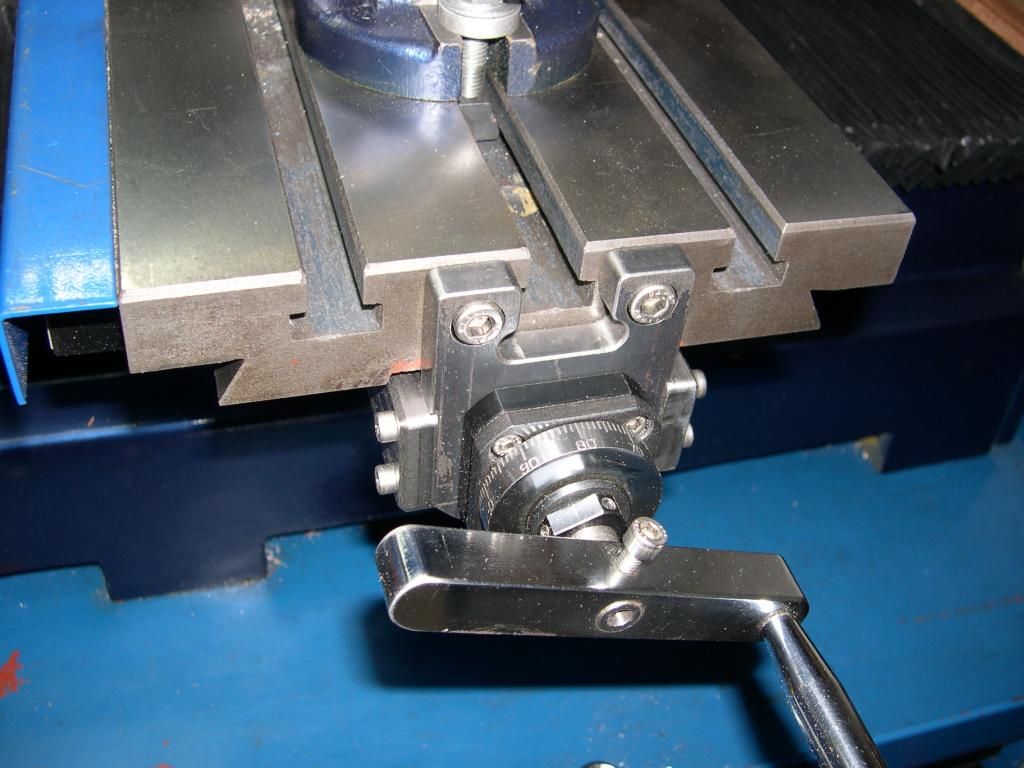

First I machined a new plate to mount to the table, designed to accommodate my new shaft bearing.

It has a bigger opening to the top to provide better clearance so that I can slide T nuts easily into the centre table slot.

It also has holes on both sides for a the braces.

I removed the table and glued some steel inserts into the slots under the table. I will use these to ground the braces. I glued these in only after I had pre-assembled the whole thing with the braces in place so everything lined up- initially I used a little epoxy putty to hold then in place.

Finally, I could assemble the whole lot. It makes the Y axis more rigid under load (I think). The eagle eyed amongst you will notice that I notched the side braces onto the front plate to help make the joint more rigid. I didn't feel the bolted joints under the table needed notches because of the loads on them.

Results 1 to 20 of 38

Threaded View

-

02-14-2015, 10:54 PM #32

Registered

Registered

- Join Date

- Aug 2013

- Posts

- 55

Re: Adding stepper power to the chuck.

Similar Threads

-

Adding a power drawbar

By ErnieD in forum Bridgeport / Hardinge MillsReplies: 0Last Post: 07-29-2010, 07:30 PM -

Adding lathe chuck to soba RT

By boxmaker in forum Benchtop MachinesReplies: 14Last Post: 04-03-2010, 09:33 AM -

Online ordering power chuck, collet chuck, MC vises form Taiwan

By mtadirect in forum News AnnouncementsReplies: 0Last Post: 08-30-2009, 03:37 AM -

adding power feed for x axis on a smithy 1220 XL

By matridium in forum CNC Machine Related ElectronicsReplies: 1Last Post: 05-30-2008, 06:43 PM -

Adding an X axis power feed to my smithy 1220XL milling table.Adding an X axis power

By matridium in forum SmithyReplies: 0Last Post: 05-28-2008, 04:37 PM

Reply With Quote

Reply With Quote