Little fix for my miss calculation, the machine oil feed groves i fitted became exposed every time i went to home or limit position, so i made up table extensions.

Results 81 to 92 of 92

-

11-14-2014, 12:16 PM #81

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

-

11-17-2014, 12:05 PM #82

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

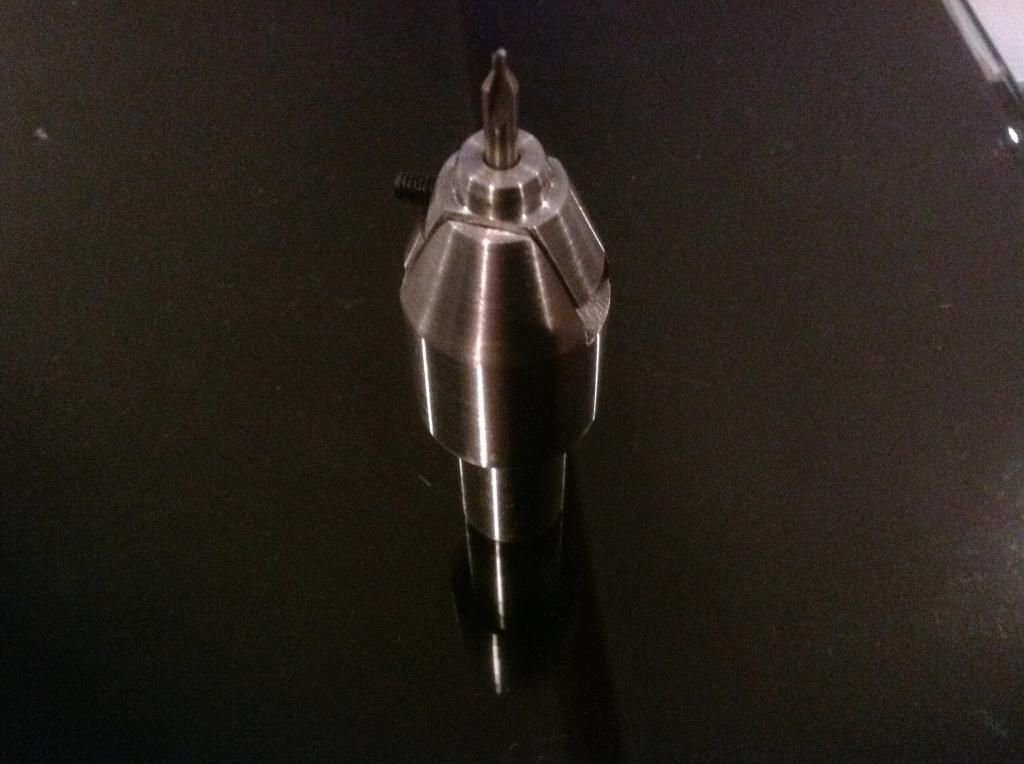

I had some issues engraving plate, i found that the slight difference in material height made the fine engraving very inconsistent, so i designed a drill holder that is lightly spring loaded, works a treat , the depth now varies via speed, only pitfall is if you go over the same area twice it goes deeper every time. very happy with the results and will probably make a new one with a Collet style chuck.

-

11-17-2014, 03:27 PM #83

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: HAFCO HM48 geared head CNC conversion

That tool is usually used prior to drilling a hole. You are using that tip to engrave?

A lazy man does it twice.

-

11-17-2014, 10:08 PM #84

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

-

11-30-2014, 01:15 AM #85

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

Here is a Facebook link to the small business we are doing if you would like to see some off the work we are doing.

https://www.facebook.com/pages/Custo...56789001022313

-

01-22-2015, 07:44 AM #86

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

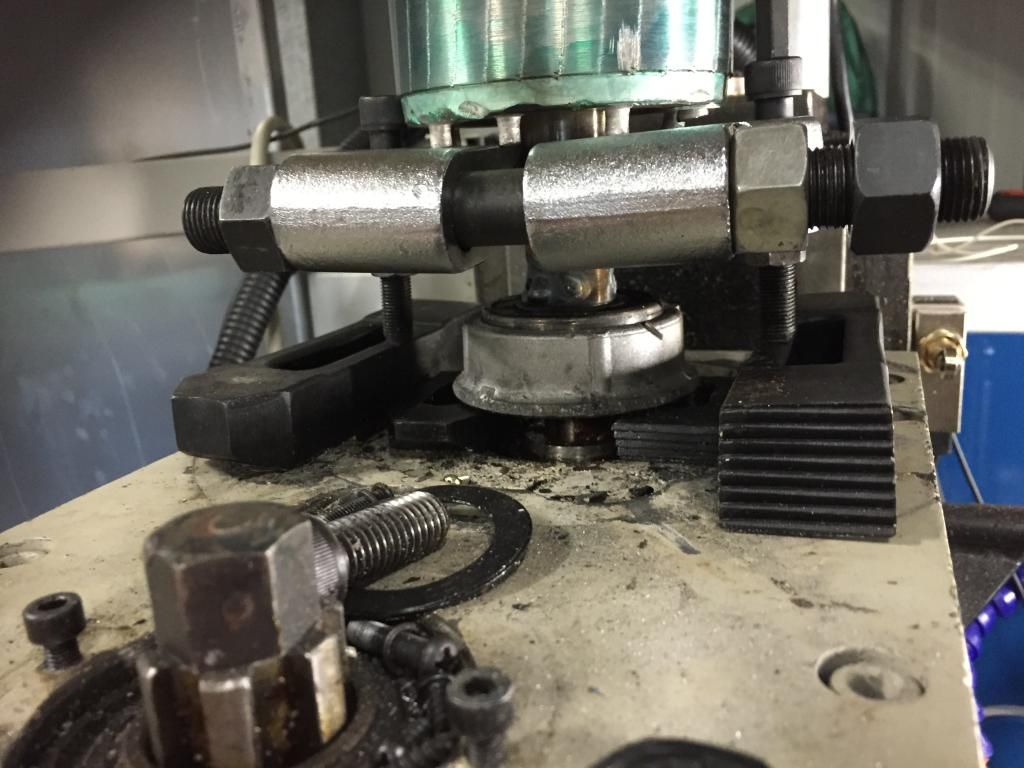

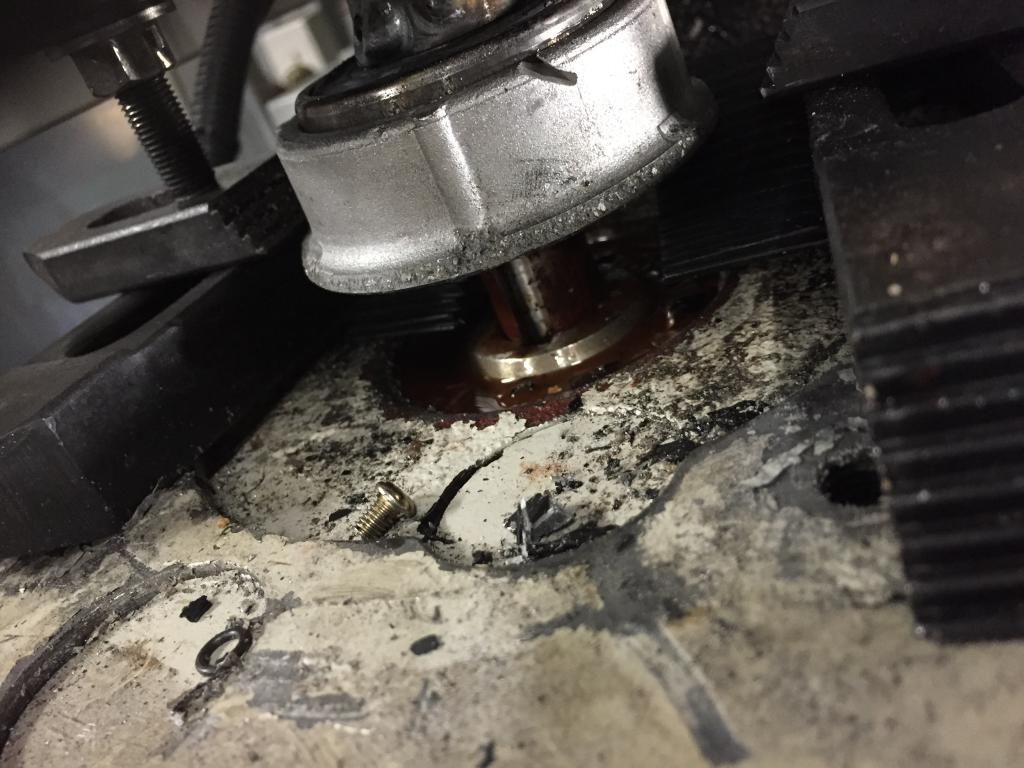

Changing to 3 phase, what a nightmare taking the motor off, was corroded in and had to be destroyed to remove sizes are all correct was just corroded together.

Such a hard just get it apart, and the frusterating bit is it just slips back together. shaft size was machined down from 24mm- 18.87mm

-

02-12-2015, 11:19 AM #87

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 20

Re: HAFCO HM48 geared head CNC conversion

What motor are you replacing it with? Any plans to upgrade the spindle to belt drive?

-

02-12-2015, 02:48 PM #88

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

I replaced it with a Delta connected 2.2 kw motor L90 frame 4 pole 91400 rpm), I had to remove the motor shaft and machine it to suit as the original shaft was 19mm with 5m key way, it appears that this was done from factory as well as the machined surface on the original motor was very poor.

Its up and running great now. I don't go over 3000 spindle rpm in high as the oil starts to froth up. also sounds like I have a slightly noisy bearing now aswell!!

Beltdrive may be to go in future.

-

03-11-2015, 06:16 AM #89

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

Slow on the updates but this is a big one I managed to get myself a new machine, as much as I like my 45- it's just not big enough sometimes, I brought a Cincinnati I plan to retrofit, 21 tool changer is what I'm excited about.

-

03-07-2016, 10:30 AM #90

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

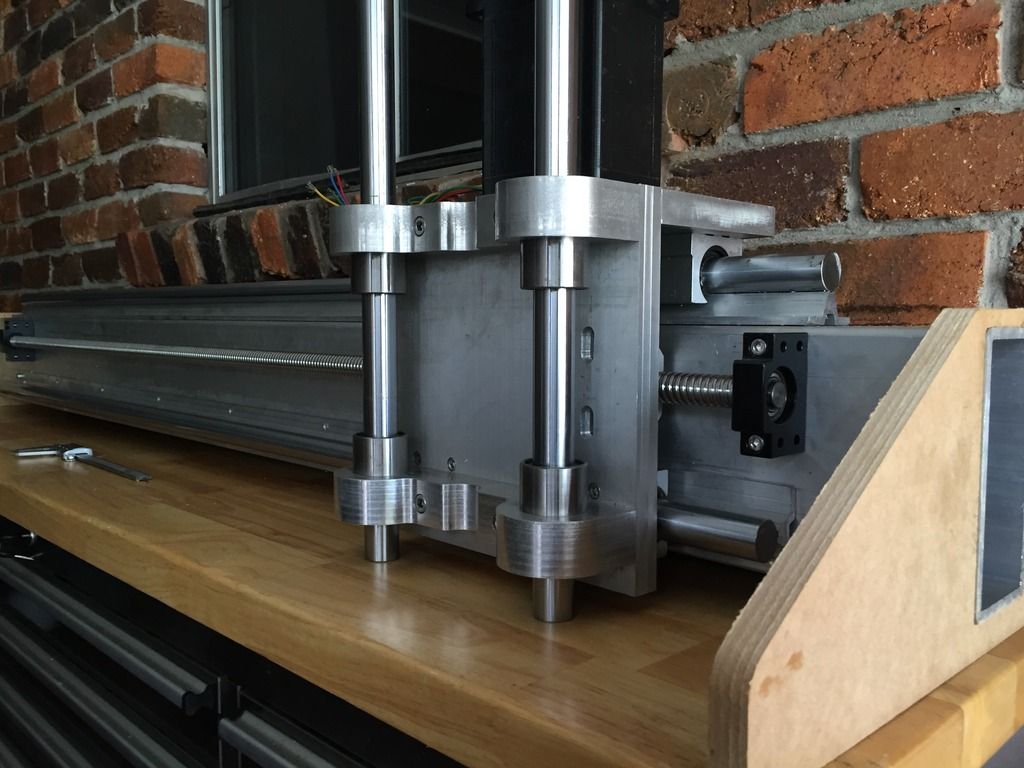

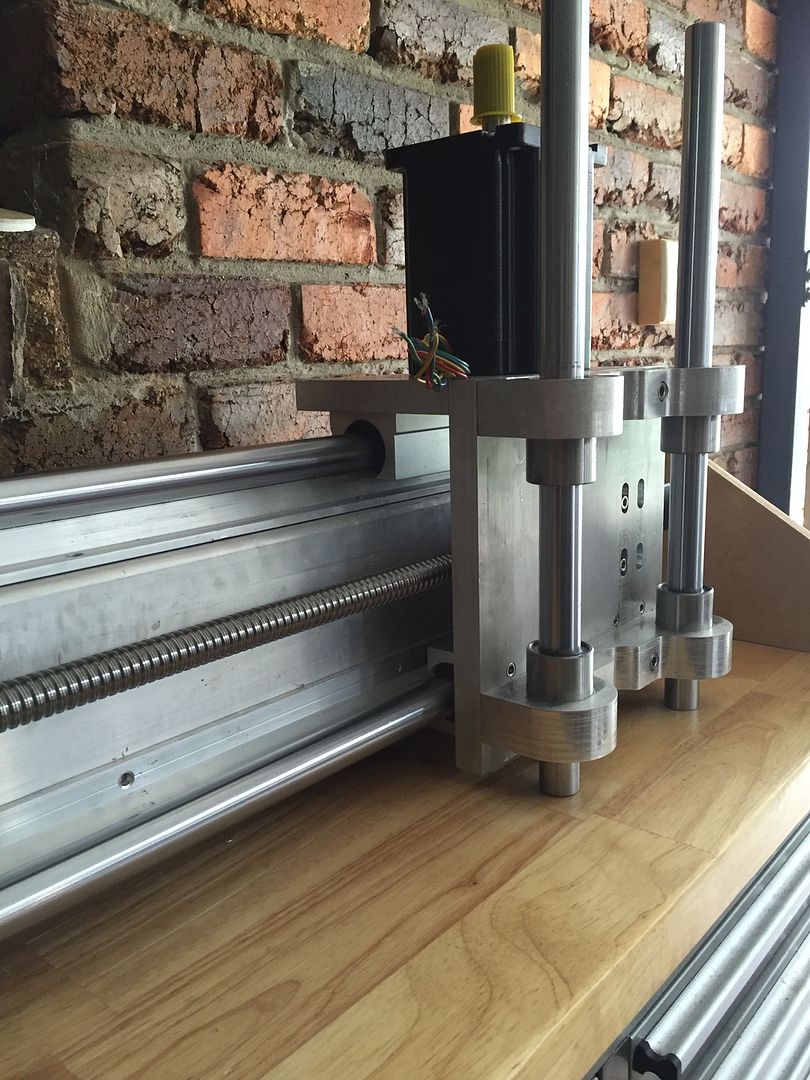

Another Slow update, i since sold the cincinati 500 and decided to make a router table. build is well underway has been designed to cut aluminum with a working enverlope of 1350x1350mm x 200mm z axis. all ballscrew driven, i have the Y axis complete and just about complete on the z axis. i am using some leftover the Y axis has a killer Nema 42 2800nm drive on it that works great so far. im achieving 10500mm/min witha 5mm ballscrew @1600 microsteps, very hapy with the build so far.

http://vid908.photobucket.com/albums...psbgoa8d1a.mp4

-

12-29-2016, 11:13 AM #91

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

got the router moving time to build the table

-

04-10-2017, 09:57 AM #92

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Re: HAFCO HM48 geared head CNC conversion

New table close to being finished, extremely rigid, ans square. table size 1300x1020 with a 300mmx1300 open section and a vertical table, this will allow end milling of longer components, and a great area to put the rotating assembly for the 4th axis. Ive learnt alot sonce conrevrting the last machine, coolant recovery is a big focus on this machine.

Similar Threads

-

CNC Conversion Help Needed - Harbor Freight Geared Head Mill Drill, Model# 42827

By TurdCurd in forum Benchtop MachinesReplies: 2Last Post: 08-07-2014, 03:17 PM -

Hafco CNC Conversion

By Johnnysilk in forum Australia, New Zealand Club HouseReplies: 8Last Post: 04-16-2013, 09:30 AM -

Lubricating Geared Head Mill

By stabbs in forum Benchtop MachinesReplies: 6Last Post: 08-17-2009, 10:43 PM -

Geared head vs. Belt drive Band saw

By ranchak in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 10-16-2008, 04:25 AM -

Want to quiet your Geared Head?

By fineartlig in forum Charter Oak Automation Support ForumReplies: 2Last Post: 10-09-2007, 03:12 AM

Reply With Quote

Reply With Quote