Hello everyone. I'm Khoa from Vietnam. After being interested in CNC for a while and having build two CNC Cframes from weld steel and used cast iron parts. I'm having me time to build a small milling machine for miniature works.

The machine travel X,Y,Z is 6x12x10".

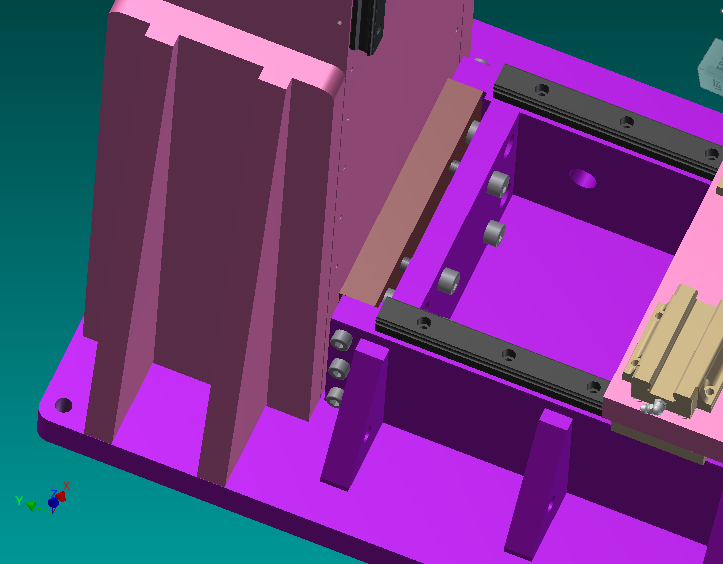

Here is its linear rails-THK SHS20:

and 2005 double nut screws:

BT30 used spindle have been taken out from a taping machine.

1.1KW Grundfus motor.

The couple:

I will use ASM66AC-N5 and N10 for XYZ axis and ASM98AC-H100 for A axiss.

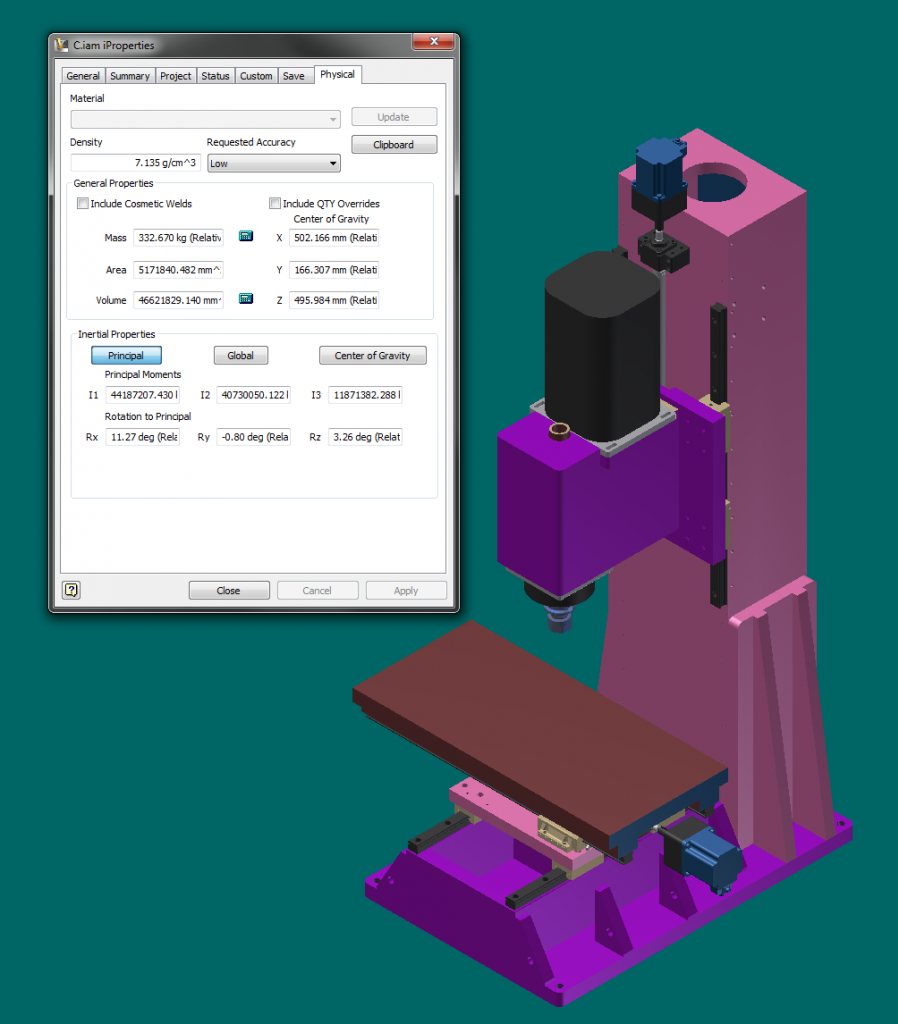

Here is the design:

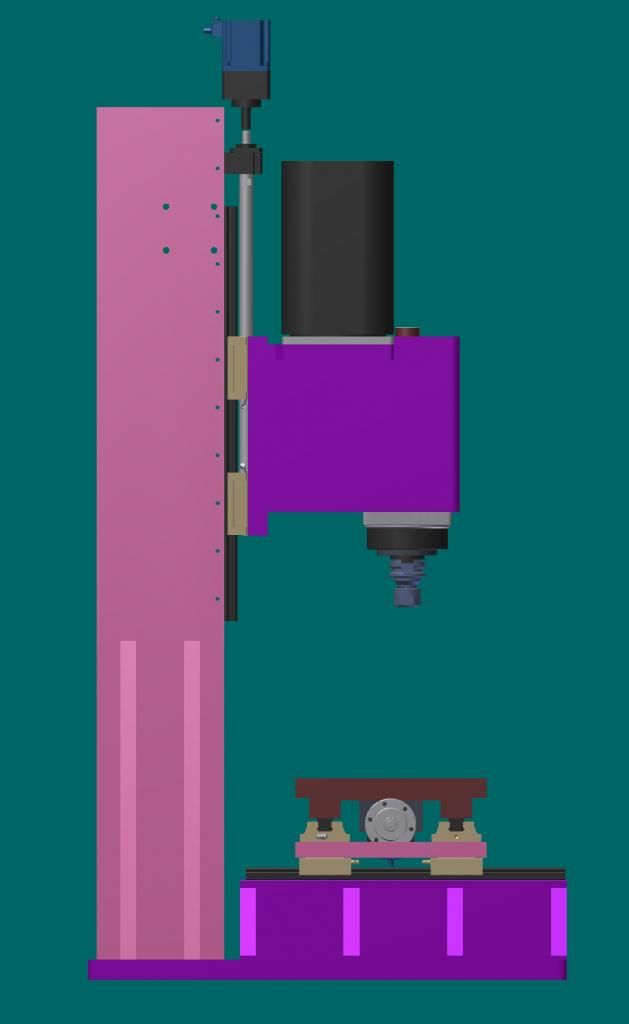

Side view:

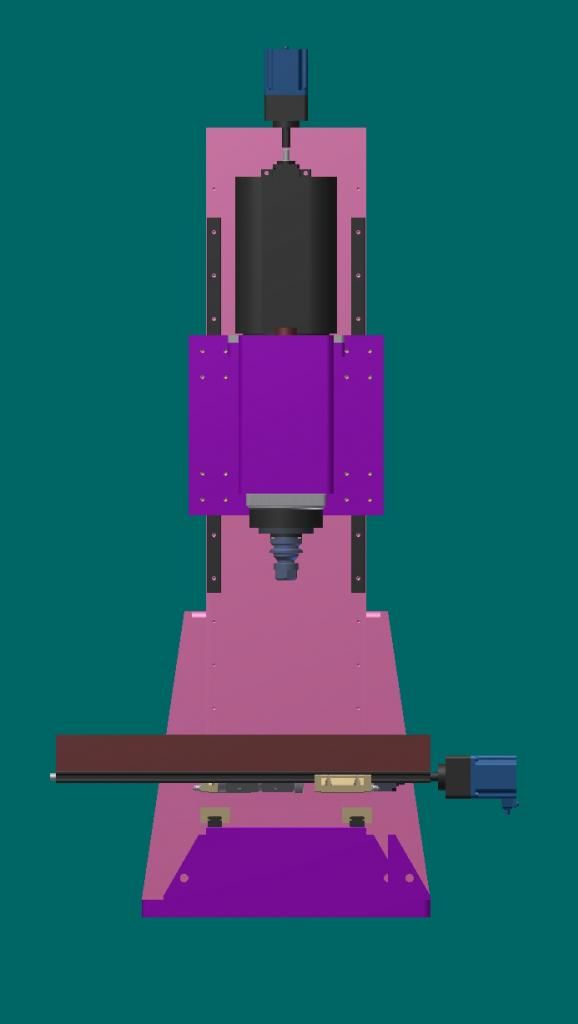

Front view:

3/4 view:

The color of this machine will be pinky like a lovely Dinah.

This structure is used for modifing the right angle between Z and XY axis.

After it's finished, all the empty parts will be filled by epoxy to make it more rigid. This machine weight is about 800 lbs.

X, Y are made from 1" weld steel. Z is used iron casting bed.

Here is some pictures of the making process:

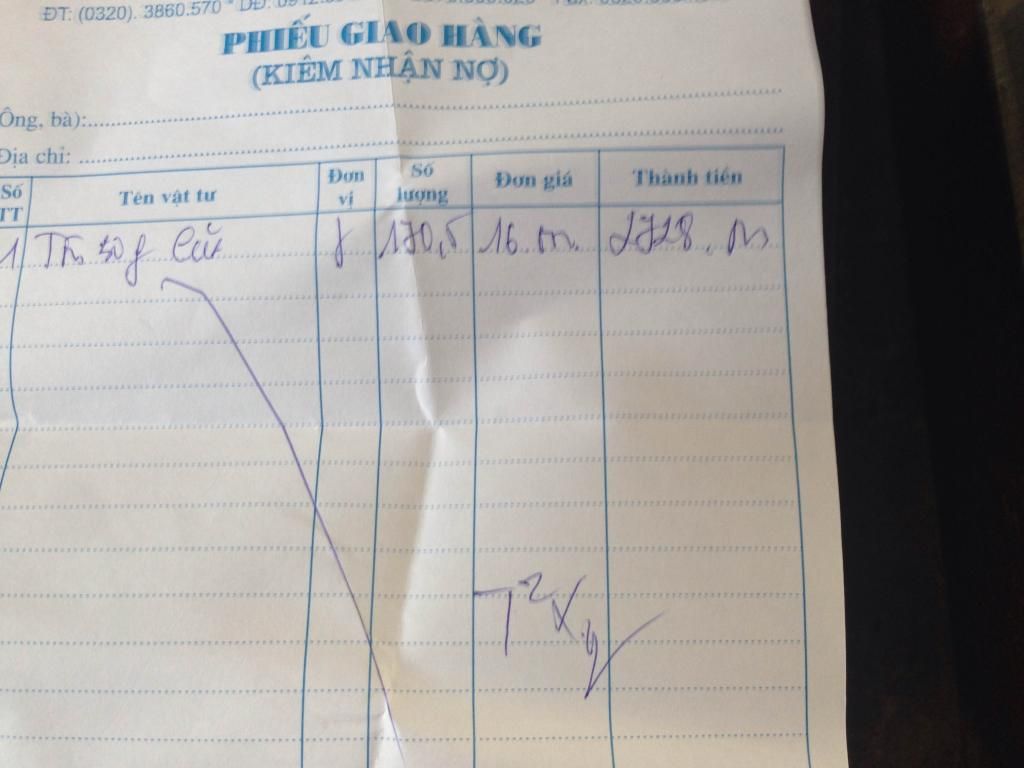

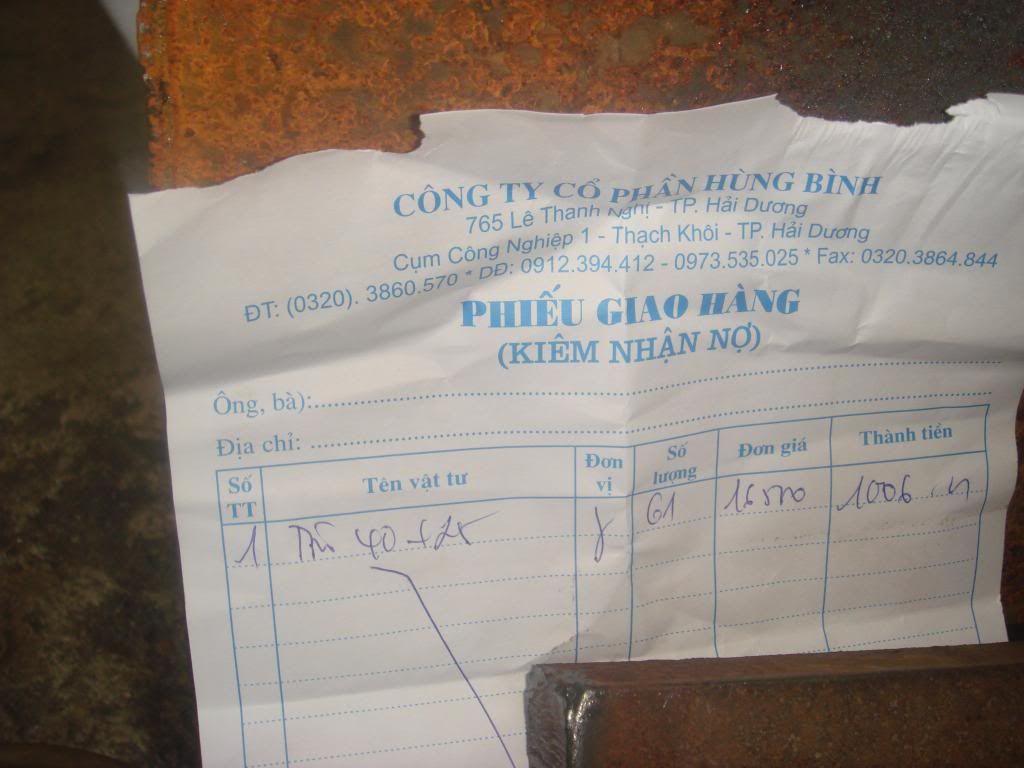

Here is steel for X table :

And the accident:

Thanks for reading. I will post more pictures about this build log while I make it.

Thread: 6x12 weld steel hobbies build.

Results 1 to 20 of 43

Threaded View

-

06-20-2014, 01:36 PM #1

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

6x12 weld steel hobbies build.

Similar Threads

-

14x14 Linear Rail Industrial Hobbies Build (Charter Oak Automation)

By nateman_doo in forum Vertical Mill, Lathe Project LogReplies: 146Last Post: 03-06-2023, 08:14 PM -

My first cnc plasma table build 6x12

By jfoster in forum Plasma, EDM / Other similar machine Project LogReplies: 8Last Post: 01-28-2018, 08:16 AM -

No-Weld Steel 1 x 0.5 x 0.2m

By Benonymous in forum DIY CNC Router Table MachinesReplies: 49Last Post: 05-16-2012, 08:44 AM -

Weld Steel Green Machine

By R L Harris in forum CNC Wood Router Project LogReplies: 210Last Post: 10-10-2011, 09:22 PM -

Industrial Hobbies Build

By Mike Ray in forum Charter Oak Automation Support ForumReplies: 11Last Post: 01-16-2009, 03:24 PM

Reply With Quote

Reply With Quote