All, Pretty new here. I'd rather not step into a Syil V's Tormach debate. Being from the UK, I did review options / price & X4+ fell within my budget.

Situation

7075 T6 150 BHN

5000 RPM, 0.82 KWh, Feed rate 150-350 mm/min

YG1 10mm High helix 2 flute Carbide

HSM toolpath created with Fusion 360 - Adaptive clearing.

Flood with Alusol A

OMG! I couldn't get the chips to clear at a sufficient rate. They started to fill the fluid exit hole, creating huge metal hills on the bed. No matter what I tried (Air = bloody mess), had to stop the job. This was only a 65mm diameter pocket, 30mm deep. Ended up with a bucket of chips albeit nice looking ones.

1st time with HSM, was using Meshcam previously (It's really keen on using the bottom 2mm of the tool, almost always). So this amount of chip clearing is a new challenge really. Incidentally, spent more time cleaning up after a HSM job than the time that the job would have saved.

Question

I can't believe that this is a super new question, but are there alternative measures I can take to get the chips out quickly whilst using flood? Increase pressure, use air simultaneously? Go back to Meshcam? Other?

Pete

Results 1 to 20 of 91

-

01-03-2016, 02:32 PM #1

Registered

Registered

- Join Date

- Dec 2015

- Posts

- 20

HSM on Syil X4+ = Aarrrgghh! Death by Chips

HSM on Syil X4+ = Aarrrgghh! Death by Chips

-

01-03-2016, 08:53 PM #2

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 861

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

I would love to see some pics of the issue (and the part, out of interest). 350mm/min isn't at all fast. What is your depth of cut? At that removal rate, with a 10mm 2-flute you don't need any fluid cooling if this is HSM-style conditions with a shallow DOC. Air alone will clear chips way better in my experience. Yes, it throws them about, but I'm guessing your machine is fully enclosed anyway.

LongRat

www.fulloption.co.uk

-

01-03-2016, 09:17 PM #3

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

I agree, I have the same issue with flood and HSM and pockets. I would suggest getting a misting system to supplement the flood and select misting coolant strategy on internal pocketing operations, that will allow the chips to be ejected nicely with the high helix endmills. Beyond that you could use high pressure and multiple nozzles which will also work but will require a pretty hefty coolant pump and large coolant reservoir or it may suck it dry before drainback (depending on your system design)..

@LongRat.... Below is a similar video showing the chip pile up in pockets whike using flood and HSM..

Go to about the 11:30 point in the video where it starts the pocket walls.. That's when chips get real..lol

https://youtu.be/vdV-rRbPDHA

Sent from my XT1080 using Tapatalk

-

01-03-2016, 09:32 PM #4

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 861

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

Lcvette - nice video. Your air line cleared the chips without any issue. I basically run a loc-line with compressed air instead of flood coolant. I can mix coolant into the line with a separate feed if it's needed but air alone is fine for 99% of jobs.

LongRat

www.fulloption.co.uk

-

01-03-2016, 09:35 PM #5

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

Never tried just an air stream.. What kind of volume are you shooting? I have a small compressor so I would prefer to not have it running all the time.. Gives me a headache..lol

With the additional misting system. It uses very little sir so the compressor turns on about every 2-3 minutes which is OK since I only use the mist for pockets and flood for everything else.

Sent from my XT1080 using Tapatalk

-

01-04-2016, 12:11 AM #6

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 861

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

Not sure what sort of CFM I run. Not really high. I have a 2HP compressor with a 50L tank and it switches on every couple of minutes.

LongRat

www.fulloption.co.uk

-

01-04-2016, 02:26 AM #7

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

At 350 mm/min, you're doing anything but HSM. At 5000 RPM, you're torturing your tool. Were you doing real HSM at 5000 RPM, you'd be feeding at over 100 IPM/2500 mm/min. With such high RPM, and low feed, you're generating a LOT of heat in the tool, an cutting VERY thin chips, which dulls the tool really quickly. You would do well to buy a copy of HSMAdvisor, and use it to calculate proper feeds and speeds.

And, with a small machine like an X4, carbide is a waste of money for any tool over 1/4". You don't have the power, RPM, or rigidity to get any benefit from carbide. HSM will do the same job for a lot less money. I do all my roughing using 1/2" HSS 2-flutes, at 6000 RPM, 115 IPM, up to 1" DOC, 0.050" WOC.

Regards,

Ray L.

-

01-04-2016, 03:18 AM #8

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

It sure where your getting your info from, but my calculator comes up with:

7075 Aluminum

.375" 2 flute carbide 42 helix

5000rpm

.0026" IPT

.500" DOC

.1125" WOC (30% step over)

26.4" IPM feed rate

That is a pretty aggressive cut for a smaller machine in 7075 which is a good bit harder then 6061..

Same parameters in 6061 bump feedrate up to 42 ipm with a .004" IPT cut.. There isn't much more I would think in a smaller machine like he has. Those chips would be pretty thick too!

Sent from my XT1080 using Tapatalk

-

01-04-2016, 03:45 AM #9

Registered

Registered

- Join Date

- Dec 2015

- Posts

- 20

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

All suggestions and comments have been really helpful. Thank you. I suspect that I'm not pushing hard enough, though clearly will quickly hit the limits of what an X4 is capable of.At 350 mm/min, you're doing anything but HSM. At 5000 RPM, you're torturing your tool. Were you doing real HSM at 5000 RPM, you'd be feeding at over 100 IPM/2500 mm/min. With such high RPM, and low feed, you're generating a LOT of heat in the tool, an cutting VERY thin chips, which dulls the tool really quickly. You would do well to buy a copy of HSMAdvisor, and use it to calculate proper feeds and speeds.

I took a good look at the chips resulting from todays experience, they're like tin foil, apostrophe shaped with a slight curl. This would explain why I'm getting a bucket out of such a small pocket.

I do like the clearing strategies adopted by Fusion 360, but as stated IPM (or mm/min) is too slow. I'll have a look at HSM advisor & research what is optimum. Paranoia over broken tools, bearings & the like does seem to get in the way of what is optimal here.

Should I bite the bullet and ramp up the feed further (Reducing the volume of chips evacuated) or stop flogging a dead horse?

For info, the X4 is only nominally 1.5KWh. Max 5000 rpm. perhaps 'HSM' in my original post was an aspiration rather than a likelihood.

Apologies - I've only been at this for the last 6 months. My profession is so far away from this space, that the learning curve has been pretty steep.

Pete

-

01-04-2016, 03:53 AM #10

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

If you use the info I posted above it should do quite well.. O use those settings on a smaller machine and it does just fine!

Sent from my XT1080 using Tapatalk

-

01-04-2016, 04:14 AM #11

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

Here is a snap shot straight from FSWizard for your tooling setup and its recommendations for 7075.. Give it a try, if it isn't happy, lower the feed per tooth or change the step over percentage, currently its at 30% or 3mm of your tool. If it doesn't seem like its taxing the machine, try increasing the feed per tooth until it looks like its struggling and back it down. You will just be adjusting the feed since you are capped at 5000rpm but it should do quite well with a 1.5kw motor I would suspect!

Sent from my XT1080 using Tapatalk

-

01-04-2016, 04:17 AM #12

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

-

01-04-2016, 04:22 AM #13

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

Yeah I've got HSM selected

Sent from my XT1080 using Tapatalk

-

01-04-2016, 04:36 AM #14

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

-

01-04-2016, 04:37 AM #15

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

-

01-04-2016, 07:45 PM #16

Registered

Registered

- Join Date

- Dec 2015

- Posts

- 20

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

This translates to 6%'ish WOC?Your stepover is way too high for HSM. Try 0.025" or 0.050".

Resulting in an imperial result of;

Material: 7075-T6 Aluminum 150 HB

Tool: 0.394in 2FL Carbide None Solid End Mill

Speed: 515.1 SFM/ 5000.0

Feed: 0.0099 in/tooth 0.0198 in/rev 99.15 in/min

Chip Thickness: 0.0048 in

Reference Chip load: 0.0032 in

Engagement: DOC0.39 in WOC0.02 in

Effective Dia: 0.394 in

Cross Section: 0.06 x Dia.

Power: 0.48HP

MRR: 0.96 in^3

Torque: 0.50 ft-lb

Max Torque: 3.86 ft-lb

Cutting Force: 30.8 lb

Deflection: 0.0001 in

Max Deflection: 0.0012 in

Do I assume that in Fusion 360 this is the parameter I should set? Terminology is mind boggling.

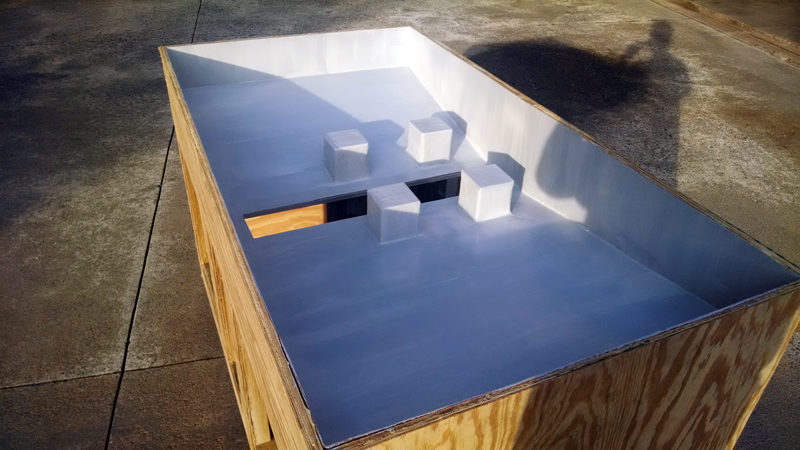

Attachment 302788

Pete

-

01-04-2016, 07:58 PM #17

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

What I'm posting above is what FSWizard kicks out for specific HSM Machining with Chip Thinning. If rpm is the limiting factor, step over is really the only way to increase MMR. I use HSM with 30% stepover and it works wonderfully with a nice meaty chip and I don't have to run super high spindle rpm, 5-6k is plenty, What your doing is making the mill go faster and cut less. But The step overs you are suggesting are bording on finishing passes.. The same MMR is accomplished with slower feed rates and bigger stepover. Even my cam software wants to run a 30-40% stepover in 6061 aluminum and it is uses Volumill which is one of the leading HSM tool path generators.

Where did you get a .025-.050" stepover from? HSM is all about constant loading not necessarily making the machine move as fast as it can.. Overall efficiency comes from a balance of the two. Not all small machines will be happy whipping around at 100+ipm feedrates. Have you tried more stepover and slower feed rates? A deeper cut avoids rubbing as well, my chips come out nice and thick and the surface finish was excellent, nice steady stream being ejected no issue with rubbing and long tool life, it still takes a nice deep depth of cut this way rarely requiring more then a single plane of machining unless I'm above 3/4" thick material.

I'm just curious why your cuts are so thin? I am guessing you just like to see the machine moving fast maybe? Or touting 100ipm feedrates?

Sent from my XT1080 using Tapatalk

-

01-04-2016, 08:26 PM #18

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

6% stepover is garbage for roughing in aluminum even 7075, .. Try it if you want, but you will have to run the mill at some serious feedrate to accomplish a chip that isn't done being cut before the cutter moves to the next tooth profile resulting in rubbing.

If you want to shake your machine to death and wear out your axis ways, go for it, otherwise I would suggest trying a more practical approach.

Below is my tried and true formula for a similarly sized endmill, it gives you the similar MMR and if using HSM constant load tool paths will cut very smooth with nice chips.

I set it up for:

10mm 2 flute carbide EM,

DOC 10mm

WOC 2.5mm (25% stepover)

5000rpm

762mm/m feedrate

.0762mm chip per tooth

I recommend starting here and working your way up, it is alot safer then trying to make your machine look like a DMG-Mori. And will get through the part very quickly with less positioning moves which will actually make part time faster then the alternative offered above.

Please let us know your impressions and results for whichever you try!

Attachment 302794

Sent from my XT1080 using Tapatalk

-

01-04-2016, 08:33 PM #19

Registered

Registered

- Join Date

- Dec 2015

- Posts

- 20

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

Right you are! Let me give it a shot and post my notes back here.

10mm 2 flute carbide EM,

DOC 10mm

WOC 2.5mm (25% stepover)

5000rpm

762mm/m feedrate

.0762mm chip per tooth

Cheers, Pete.

-

01-04-2016, 09:45 PM #20

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: HSM on Syil X4+ = Aarrrgghh! Death by Chips

We seem to have strayed far away from answering the original question. If you're drain is plugging with chips then a bigger drain is in order or another method of chip control. I went big full slot under the mill with a chip drawer the same size down to the fluid pan.

Similar Threads

-

Need some rectangular chips cut to replace CF chips that are cracking

By Lens4Hire in forum Employment OpportunityReplies: 1Last Post: 03-14-2014, 04:47 PM -

Scrap value quesiton, chips vs chunks. Coolant mixed with chips?

By trialanderror in forum Uncategorised MetalWorking MachinesReplies: 5Last Post: 10-04-2013, 12:08 AM -

Power Drawbar/prototype ATC Syil China/ Syil Canada/ Syil North America

By syil canada in forum News AnnouncementsReplies: 39Last Post: 08-07-2010, 04:59 AM -

new retractable 56,000 Air spindle, Syil China / Syil Canada / Syil North America

By syil canada in forum News AnnouncementsReplies: 6Last Post: 05-13-2010, 12:52 PM -

Cook your chips to make more chips :)

By ToMMY2ooo in forum Bending, Forging, Extrusion...Replies: 3Last Post: 09-07-2004, 07:38 PM

Reply With Quote

Reply With Quote