I thought I would make a thread on the conversion of my SX3 to a CNC-Manual machine. Im calling it a cnc-manual as it is the only mill I will have in the workshop and therefore it needs to be quick and easy to use like a manual with all the tricks of a full functioning machining center. I have taken inspiration from many conversions documented on this site so I must thank all of you. Any comments or questions are welcome. I originally bought the machine to keep as a manual until I finished university and had some more money but that changed when the issues stated appearing, more to follow....

I bought my standard SX3 from the sieg importers - arceuro trade in the UK and had it delivered just after Christmas right onto my doorstep. Literally onto my doorstep as the driver wouldn't put it in the garden due to the narrow access.

This actually blocked the enterence to my house and I had to climb over it to get out.

Just to set the scene, here in the UK space is stupidly expensive and my workshop is a 10ft x 8ft shed that is shared with the lawn mower and the only access apart from through the house is a long narrow walk way which was too narrow for the massive box.

I couldn't move the box as it was too heavy and it was blocking the door and it started to rain. So all I could do was to remove the front panel and start to dismantle in the street. The girlfriend wasn't too pleased at this point and its a good job we have wooden floors!

I was able to remove the chunky parts and drag it into the hallway to close the front door.

After getting it own to a state where me and friend could lift it, it was moved through the house into the shed. That, sadly was the last time that the milling machine was in one piece, I would love to be as oblivious to the problems hidden as I was then. I had fallen into the trap of the cheap chinese mill.

At this point I have to say that these machines are cheap, BUT some of the things I found were just plain baffling and probably took more time to cock up to the level that they did than it would've taken to fix properly. So, I started to re-assemble thinking that this was going to be a good manual machine. I then had a closer look at the Z axis gib strip, being the first thing out of the box after the degrease, and found that the sliding surface looked like it had been scraped with an angle grinder. I have circled the 5-6 spots providing the mating surface.

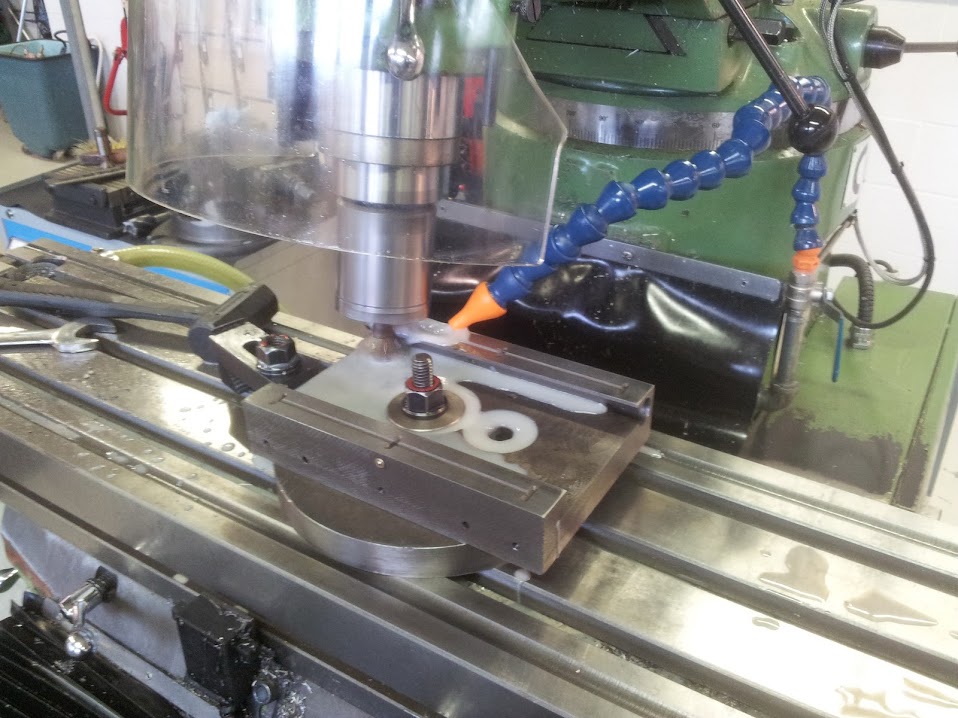

This was not helped by the fact that the tapers between the sliding head and the gib didn't match so an even pressure couldn't be applied anyway. There are people on here that get away with much scraping and cleaning up but I decided to scrap it and make a new parallel gib from gauge plate with proper adjusting screws. This is were having access to a university workshop and bridgeport type machines came in handy.

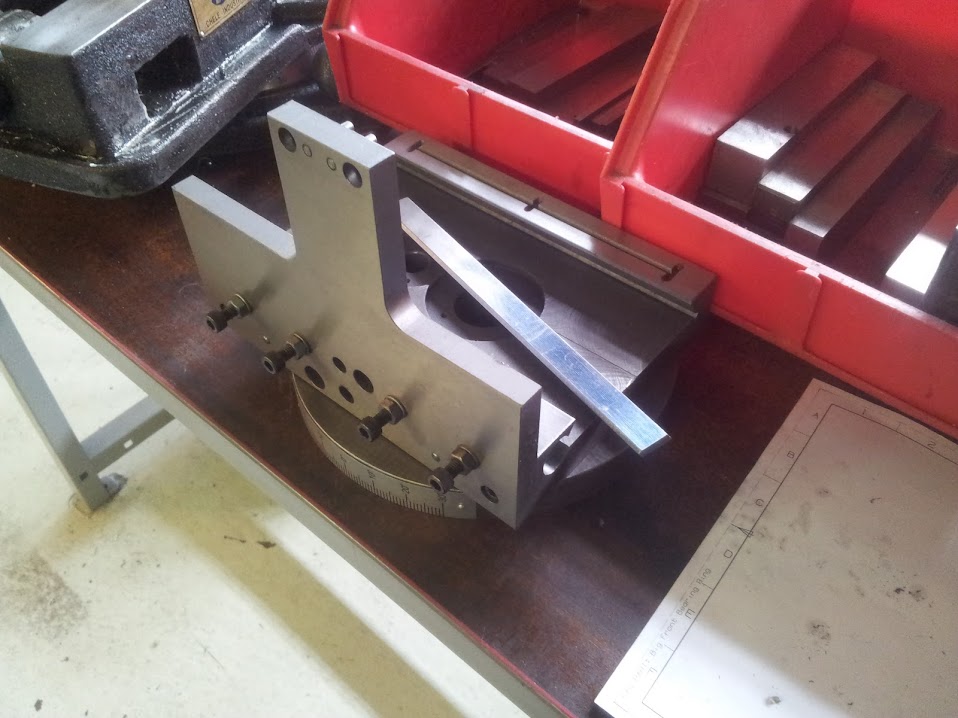

The taper was totally removed and made parallel. I had to tip the head of the mill over to recreate the 55 degree dovetail on the column. Any idea why they use 55 degrees?

A new gib was machined from gauge plate and surface ground to ensure parallelism.

The sliding head had new M8 threaded holes drilled and the side plate was drilled a generous clearance for the adjusting screws, a very satisfactory result but it took a lot of work.

At this stage I took a little tangent and decided to change to colour from the standard red to a Tom Senior Green, everything was given a good degrease and the enamel given two coats.

I also started to install the lubrication system by grinding small channels in the Y mating surface, they are not very pretty but they do the job. A small hole is drilled through the base and they are tapped M8 fine on the underside to accept the dose limiters.

This will be a manual one shot system eventually going to all three axis.

More to follow...

Thread: Robs SX3 CNC-Manual Conversion

Results 1 to 10 of 10

-

06-18-2013, 09:35 PM #1

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 17

Robs SX3 CNC-Manual Conversion

Robs SX3 CNC-Manual Conversion

-

06-19-2013, 01:31 AM #2

Gold Member

Gold Member

- Join Date

- Sep 2012

- Posts

- 1543

Looks interesting, I'm following!

-

06-28-2013, 12:49 PM #3

Junior Member

Junior Member

- Join Date

- Jun 2011

- Posts

- 17

Hey Rob, I am thinking about buying an SX3 too and have a similar issue to you - access!

My workshop is a spare room in my (first floor!) apartment - I have an SC4 lathe and managed

to get this upstairs with the help of the delivery driver (who earned himself a hefty tip)

The SX3 is a good deal heavier though, and when I called Arc Euro Trade they told me the delivery

driver will drop it on the street/driveway and that's it...

So I will be in a similar position to you, Arc pointed me to their disassembly guide, which is excellent

but are not interested in offering any further advice - I was hoping not to have to strip it down completely

to get it indoors, just perhaps the column, head, base and possibly table, so the component parts

are capable of being carried up a short flight of stairs and along a corridor

In your experience, are these components light enough to be carried by one? two? people...I see you left the

base attached to the column? I can get a stair climbing sack truck from the office but am trying to gauge

if this is a one man job or not (they deliver Mon - Fri)

If I can get it inside, over the weekend I can get one or two friends to help with the re-assembly but have this nightmare

of having it bits on my driveway, and finding I still can't shift it, and the rain clouds gathering <g>

I have no problem going through the disassembly guide step by step but would prefer to do this indoors (at my leisure) so

was hoping for an abridged version from Arc (don't need to completely strip the head to move it surely - but perhaps only disconnect

the cables and unbolt from the pivot?) but as I say they were not interested in offering further advice

I'll get the custom stand and can (hopefully) reassemble it in situ, so I don't have to lift the whole thing complete onto the stand

Any advice would be appreciated (as an aside I am in Exeter in the UK) - I am a beginner at all this, lathe was delivered in Dec 2012

and this was the first time I have ever used one!

(I did a course in Axminster Tool Centre on the lathe and will do their mill course as well, they

are just up the road from me)

Best wishes

Chris

-

07-01-2013, 06:28 PM #4

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 1015

most parts of that machine are two person carry. the column, base and head are all heavy enough that i wouldn't risk moving on your own. if you have a moving dolly you could probably do it, but i definitely wouldn't lift them by myself.

-

07-02-2013, 03:45 PM #5

Junior Member

Junior Member

- Join Date

- Jun 2011

- Posts

- 17

Thanks - I am coming to the same conclusion, perhaps I will wait for the weekend and get one of my friends to come around and help - or even better, two friends, and I can watch and supervise <g>

Joking aside, even if I could shift it with a sack truck on my own it's better to have someone else there just in case perhaps

I can see myself doing my back in or dropping something heavy on my foot (again!)

Regards

Chris

-

08-22-2013, 10:34 AM #6

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 17

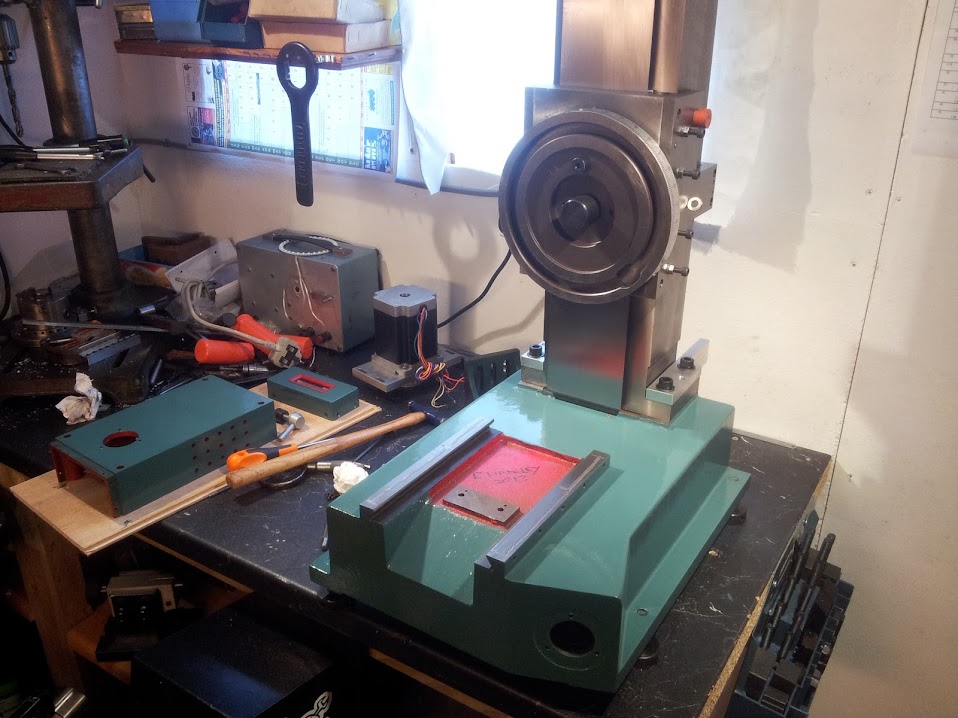

Hi All, sorry I’ve been so quiet recently, it’s been really busy for me finishing Uni and starting work.

I will update showing where I am and how I got there later but at the moment all I want to do is get it working.

Attached is a photograph of what it looks like now! A bit different eh?

I Have a question, in the second photograph attached there is a rogue blue wire which has had its end removed accidentally and I’m not sure where it goes. Can someone post some decent photographs of the circuitry in the back of the sx3 so I can trace it, the photographs I took don’t show the details hidden behind some of the panelling which is annoying.

Thanks all, Rob.

-

08-22-2013, 05:44 PM #7

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 124

-

08-22-2013, 06:21 PM #8

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 17

Nope, thats where the power to the motor goes. The blue wire is much smaller in section than the mains wire

Help! its stopping me from finishing it

-

08-22-2013, 09:08 PM #9

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 124

All the wires were capped, that one has come out of it's cap/hub/thing, so just look around? One spot has to be missing or unplugged. O.o

-

08-23-2013, 12:16 PM #10

Junior Member

Junior Member

- Join Date

- Jun 2011

- Posts

- 17

Missing wire?

You probably already know about this, but there is an SX3 dismantling guide on the ArcEuroTrade website that has a few pictures of the wiring loom?

Also, there is also a copy of the wiring diagram in the manual linked below with the cable colours marked? (and a few more images)

http://cdn0.grizzly.com/manuals/g0619_m.pdf

I have attached the page with the wiring diagram

Regards

Chris

Similar Threads

-

Jet 1600 ZX (2004) Manual to CNC Conversion

By kb18951452 in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 10-17-2010, 12:58 AM -

Info on manual to CNC conversion needed

By eoinie in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 03-30-2010, 06:27 PM -

Manual lathe conversion to CNC -

By jdmech in forum Uncategorised MetalWorking MachinesReplies: 2Last Post: 10-02-2006, 10:32 PM -

Manual lathe CNC conversion

By kong in forum Uncategorised MetalWorking MachinesReplies: 10Last Post: 08-20-2005, 09:56 PM -

Manual EDM to CNC conversion

By Jim Estes in forum Waterjet General TopicsReplies: 13Last Post: 03-15-2005, 02:06 PM

Reply With Quote

Reply With Quote