I guess the only real negative is it's different than what I normally do at work when I get to play with the CNC's. Mainly the HAAS TL2 lathe. I set all my tools in the Z off the face of the chuck with the G54 set at 0. Then I can set my G54 Z offset with any of the tools and they all relative.

Maybe what I want to do Is similar to the master tool process?

Just trying to keep things the same.

I only have the edge finder lights up when it makes contact. A Haimer is on the wish list. Someday!

Andrew

Thread: Andrew's G07040 build

Results 221 to 240 of 241

-

04-21-2016, 07:47 PM #221

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

-

04-21-2016, 07:54 PM #222

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

-

04-21-2016, 08:29 PM #223

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Andrew's G07040 build

That is very similar to how the master tool mode works. You essentially measure the distance from the nose of the spindle to the table or in my case the touch plate. Now MSM knows that distance. Now you measure the tool that you will use as your master tool. In my case that is my touch probe. I use the probe to set my WC offset to what ever I have defined in my code and then each tool after that is measured and the length offset is adjusted relative to the master tool.

This method works great for both repeatable height tool holders and well as non-repeatable.

-

04-23-2016, 06:19 PM #224

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

Just spent the morning working on getting my machine using the wireless tool length off-setter

Started out trying to figure out Vb-script on my own..........:drowning:

Then I went and started the trial for the MSM screen set. There is a rather big manual with a LOT of info to take in.

Holly hell is that a nice screen set! I don't think there's much you can't do with it.

I think it is worth every last penny it costs for the pro version. Once I got all the settings in ( finding some of them is a bit mind bending ) I was able to do my tool length settings off of the tool setter and then use my Tormach light up edge finder to do a Z work offset like I wanted :banana: :banana:

Then I was able to run my proven programs without much issue, there are some G28's at the beginning. need to sort that out in fusion 360.

Most progressive day with the machine in a very long time. I can't thank Kenny Duval enough for recommending it MSM!

Andrew

-

04-23-2016, 07:16 PM #225

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 962

Re: Andrew's G07040 build

+1 on MSM .. I'm a long term, & very satisfied user. Great product & great support.

Dave was very helpful in getting my automatic retractable tool setter up & operating smoothly.

https://www.youtube.com/watch?v=hoVivgo3jhk

-

06-09-2016, 08:55 AM #226

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

I was asked If I would share the CAD for the stepper back covers I made so I figured I would just put them in the Build log for all to grab.

Credit is due to hoss2006 for the original files. I used his .STP files as a starting point and dumbed them way down to 2D. I don't have any hole location for attaching the two pieces as I did it on the fly after they were machined.

Enjoy!

Andrew

-

06-09-2016, 05:25 PM #227

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: Andrew's G07040 build

Very nice work.

What kind of screw on 4 pin connector is that?A lazy man does it twice.

-

06-10-2016, 04:52 AM #228

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

I believe these are the ones I ordered.

7231-13501-9710050 | Bullkhead Connector: 4-pin, male, 0.5m length

Andrew

-

06-12-2016, 10:07 PM #229

Registered

Registered

- Join Date

- Oct 2004

- Posts

- 56

Re: Andrew's G07040 build

Andrew,

Did you think of threading the hole in the end cover to screw the bulkhead connector into? The spec sheet say M16x1.5, so I may leave a bit more wall thickness where I thread it.

Rod

-

06-13-2016, 04:13 AM #230

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

Not really. There are flats on the side of that end, so I just milled a hole to match the shape and used the locking nut that was supplied.

That also let me keep it in the orientation I wanted for my cables to connect.

Andrew

-

12-05-2016, 05:43 AM #231

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

-

12-05-2016, 06:10 AM #232

Registered

Registered

- Join Date

- Apr 2015

- Posts

- 72

Re: Andrew's G07040 build

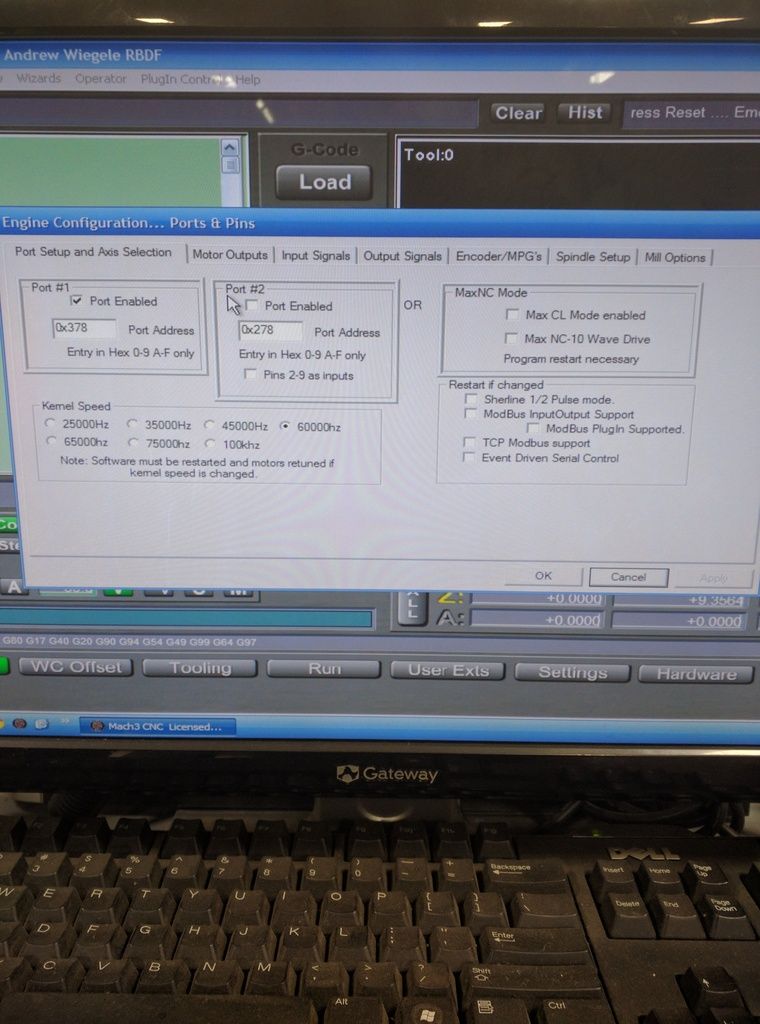

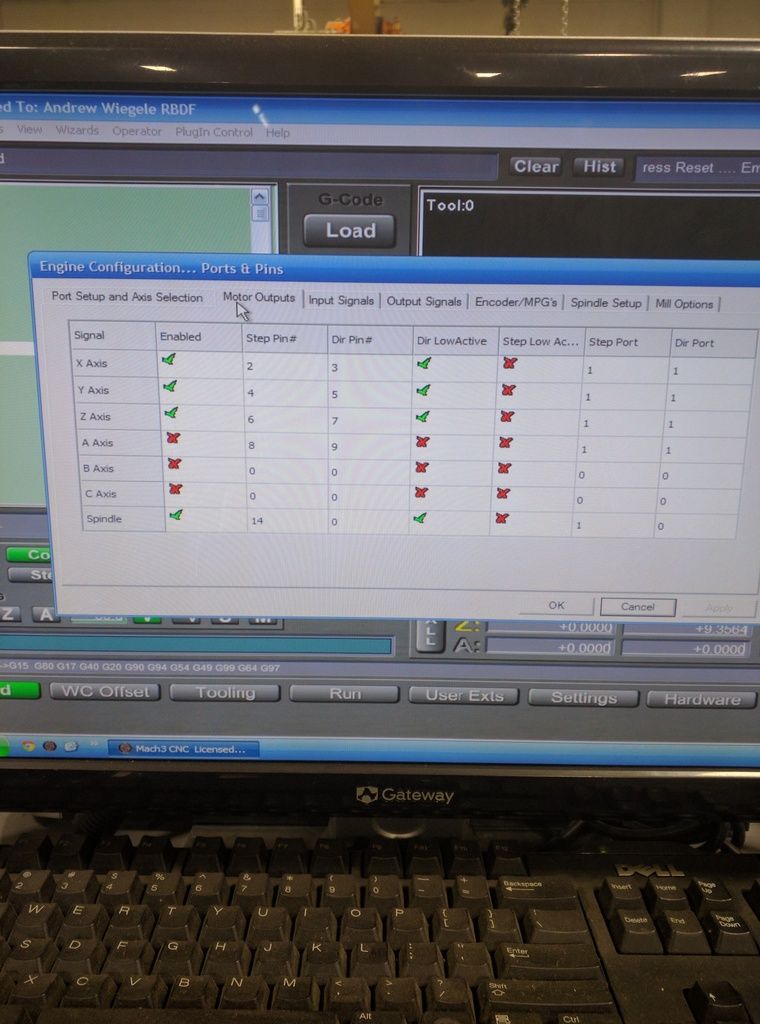

Great thanks, looks like you are using 1/8 microstepping? Any reason not to go more, right now i have mine setup for 1/16. Everything else I have setup the same, the only difference I see is that you have your "StepLowActive" set to off. Where as the documentation for the MX4660 says "step and direction signal voltage should be 3.3-5VDC and Active High"

How has the kernal speed of 60000hz been working so far? I have mine set at 25000 but im not exactly sure what it even does.

-

12-05-2016, 02:53 PM #233

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: Andrew's G07040 build

Maybe a little explanation on microstepping. A standard stepper has 200 steps per revolution not including ballscrews or gearing. If you select 1/8, you now have 1600 steps per revolution (theoretically). If 1/16 you have 3200 steps per revolution. My screws require 5 turns to travel an inch. So for the machine to travel 1" the stepper would have to receive 1000 steps if there was NO microstepping (those steps would be .001), now factor in 1/8 microstepping. This would require 8000 steps, 1"/8000=.000125" traveled per step (again this is theoretical). Do you think your machine is accurate enough to use this?, the answer is no.

Now in regards to the kernel speed selected (Mach recommends 25000). This is how many commands can be given at a time. The higher the microstepping the more signals need to be sent.

Hope that muddied the waters.A lazy man does it twice.

-

12-05-2016, 06:23 PM #234

Member

Member

- Join Date

- Dec 2015

- Posts

- 923

Re: Andrew's G07040 build

Now that you have had some time to use it, how's the wireless tool height setter working? I'm looking to add one to my setup.

-

12-06-2016, 03:52 AM #235

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 205

Re: Andrew's G07040 build

I think the muddy water has leaked into my brain, but ...

Accuracy, repeat ability, and increment ability (put that in your dictionary) are three different things, especially with backlash and backlash compensation.

You can make parts with a lathe cross feed far more accurate than the accuracy of the machine.

I can't properly explain these things, but I know they exist.

Don

And remember when going through Hell keep going!!

-

12-06-2016, 05:32 PM #236

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1943

Re: Andrew's G07040 build

Kernel speed is the maximum stepping rate. So at 25000Hz, you can send 25000 steps/sec or 1,500,000 steps/min.

Extreme microstepping does nothing for you really. Due to the way steppers work, microstepping can smooth rotation when rotating slowly, but at higher speeds really doesn't get you anything. In terms of accuracy, you only get guaranteed accuracy to 1/2 microstepping.

For example, lets say you have 1/4 microstepping selected and assume a perfect machine with no backlash, or friction that moves exactly 0.001" with every full step of the stepper. If you select 1/4 microstepping and command a 1/2 step, the machine will move exactly 0.0005", but if you command a 1/4 step, the perfect machine won't necessarily move 0.00025", it will be somewhere between 0 and 0.0005", but could be 0.0003". Better than full stepping or even 1/2 stepping, but only up to a point. In my opinion anything more than about 1/10 microstepping is useless. Just so happens that Gecko drive use 1/10 microstepping. Setting it higher really gains nothing.

Now back to kernel speed. Remember that 25kHz gets you 1,500,000 step commands per minute, and if you have 1/10 microstepping there are 200*10=2000 microsteps per rev, so 1,500,000/2000=750 RPM maximum. 60kHz will get you 60,000 * 60 /2000 = 1800 RPM, but steppers generally don't work well at this speed and about 1000-1200 RPM is about the max reliable you can expect without losing steps.

Lets say you have drivers that can do 1/256 microstepping. At 25kHz that would be 200*256=51,200 microsteps per rev. Then 1,500,000/51,200=29 rpm max. A blistering pace.

So, in general, my opinion is use microstepping to about 1/10, maybe 1/16, but no higher, and set your kernel sped to get you about 1200 rpm. If you do the math, that means about 40kHz. I believe Mach 3 has a 45kHz setting that is the closest and from what i have read is the most popular kernel speed for stepper machines.

I personally us LinuxCNC, and GRBL. GRBL has a max step rate of 30kHz, and I have my linuxCNC setup to achieve that 30kHz as well. I run 1/8 microstepping on my drives and for my machine that works out to 1125 rpm on the steppers and 225 inches per minute, which is just about perfect for my machine.

-

12-07-2016, 08:58 AM #237

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

@janz99

To be honest, I don't really remember when I set it to 60kHz......... If I had to guess, it would have been before while I was trying to get rid of the "clicking" my steppers were doing. the ESS fixed that.

@CL_MotoTech

To be even more honest, the machine has sat in the corner at work for the last 7~8 months untouched. So I haven't put the tool setter to much use yet.

Had a ton of fun getting the control computer working to try and make parts this past weekend. Last time I used it I installed MachStdMill Pro screen set (which I really enjoy using). So the trial was up and I had to buy the full license. Not a big deal, but you need to activate it via the internet OR a proxy setup. Well the proxy was giving me an error on the control computer so I couldn't create the files needed to go to an online computer to activate. the control computer is not setup to connect to my works network. And my phone and windows XP would not play nice and tether.

Eventually I found the right drivers online to get the tether to work. But ended up only machining 1 part in the 6'ish hours I was at work. Only needed 15~20 min worth of machining time!

Andrew

-

12-07-2016, 08:27 PM #238

Member

Member

- Join Date

- Dec 2015

- Posts

- 923

Re: Andrew's G07040 build

Bummer man. Yeah i've been doing the combo touch probe / tool height setter thing and switching it back and forth is getting pretty old. So I am thinking about leaving the probe as the probe and getting another tool height setter. I may just go for a touch plate at this point, I can't decide. Yeah, MSM is great. Not sure how I survived before it.

-

12-13-2016, 09:39 AM #239

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

janz99,

Your inbox was full so I put a reply here

Here's a link to the post where I show what I got and link to the store site

http://www.cnczone.com/forums/bencht...ml#post1496912

Andrew

Originally Posted by janz99

Originally Posted by janz99

-

12-13-2016, 10:05 PM #240

Registered

Registered

- Join Date

- Apr 2015

- Posts

- 72

Re: Andrew's G07040 build

Great thanks!! The hose guards are a nice touch, I really like it. Do you happen to know what the thread size is for the ball nuts?

From your pictures, it looks like the the hose connects to the metering valves by some sort of swivel?

Similar Threads

-

Andrew's G0704 CNC Conversion

By andrew2085 in forum Benchtop MachinesReplies: 12Last Post: 01-21-2013, 06:04 PM -

Mint's Build Aluminum/Steel Build thread.

By FreshMint in forum Maintenance DIY DiscussionReplies: 0Last Post: 10-31-2011, 04:18 AM -

Newbie - To build or not to build Router/Plasma Table

By dfranks in forum Waterjet General TopicsReplies: 10Last Post: 04-08-2011, 05:16 AM

Reply With Quote

Reply With Quote