You lose all your swing if you have it mounted across the ways!

The other thing you must have is repeatability.

CNC lathes require tool tables and known locations of tools. (it's easy on a mill, the cutting edge is the outside of the diameter so that's all you need to know. On a lathe you need to know where the cutting edge is in X&Z)

Results 41 to 60 of 235

-

03-13-2013, 12:38 PM #41

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1531

7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

03-13-2013, 07:53 PM #42

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

pippin,

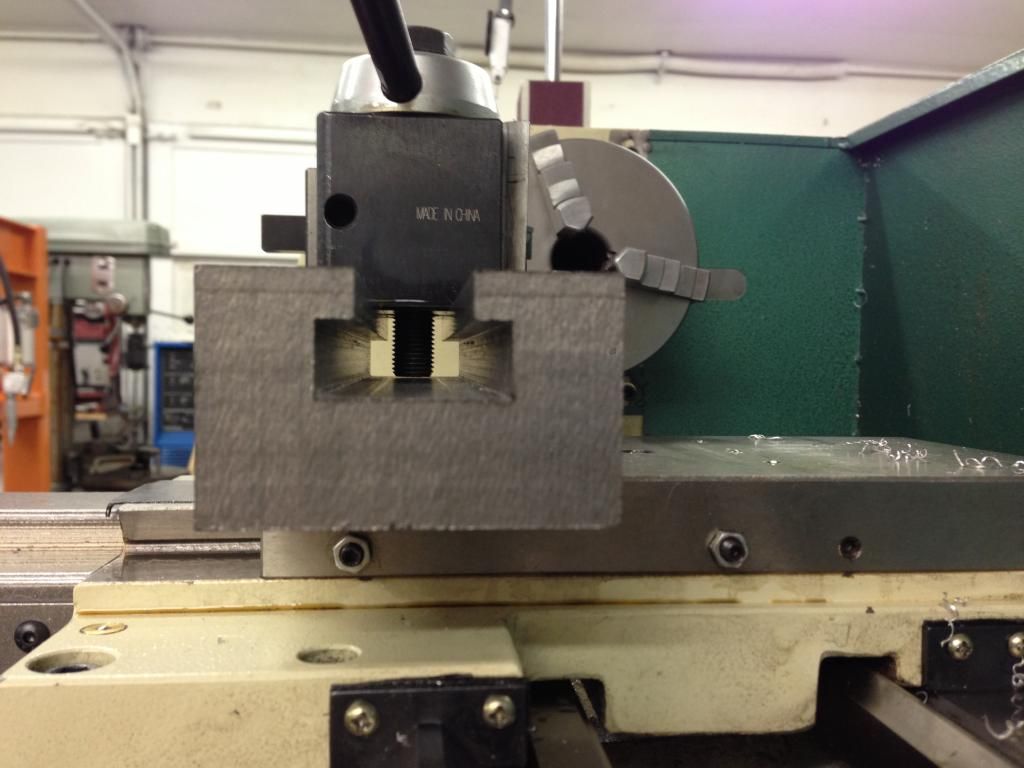

I agree I don't want to loose any swing, just trying out different setup options at the moment. My mentor is going to stop by Thursday night and brainstorm some tool post ideas with me. He has 30+ years of CNC mill lathe experience, it will be interesting to hear what he has to say. Trying to come up with something simple but rigid and functional. This is how I have the tool post mounted at the moment for testing purposes.

-

03-15-2013, 04:15 AM #43

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

My C41 board arrived today. Set up Mach3 turn to output PWM step signal and now my output voltage is perfectly stable. There was something wrong with my C6 board for sure. We tried EVERYTHING. One other nice thing with the C41 is that it has CAT 5 out to the VFD. The C6 that I had only had a CAT5 in for the input signal. I just snipped a CAT5 I had laying around and wired it into the VFD and plugged the other end into the C41. Nice and clean and shielded to boot.

-

03-15-2013, 06:25 AM #44

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Got things moving around this evening. Hooked up the motors and did a quick and dirty calibration. She is working GREAT so far!

http://www.youtube.com/watch?v=6sTjhAfAFr8

A little constant speed action.

http://www.youtube.com/watch?v=bX7LJ...ature=youtu.be

Making a 30 deg point.

http://www.youtube.com/watch?v=6_8V_...ature=youtu.be

-

03-15-2013, 10:13 AM #45

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 41

Looking absolutely fantastic, Matt, may I ask what CAM you're using?

Thanks for sharing-

-

03-15-2013, 02:26 PM #46

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

-

03-15-2013, 02:32 PM #47

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 41

Ok, thanks for that. I'm looking at what's available for Lathe (CAM) out there and so far the most reasonable thing (for me anyway) is Dolphin.

Thanks again, and I look forward to see the progress-

-

03-15-2013, 06:07 PM #48

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 101

-

03-17-2013, 01:29 AM #49

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

I need to stop fooling around with the lathe and finishing this thing up. My mentor came over last night. We messed around with various tool post ideas. We have decided to machine a new tool post mount at his place in the next week or so. Probably cast iron or steel. It will have a dove tail and allow for a couple of different setups. He seemed fairly impressed with the lathe, at least a lot more so than when it was in the manual configuration. I have not plowed the tool post into the chuck yet at 3000 RPM. I need to place a big Estop on the front of this thing. I also need to put an external braking resistor on the VFD. The VFD internal braking resistor is not up to par with the rapid speed changes (the TECO manual confirms this and recommends an external resistor). I will get a OVER CURRENT error if i set my deceleration too aggressive when using higher RPM. At the moment I am running around 3000 rpm peak spindle speed. The spindle bearings are staying cool with the Kluber grease. Other then that the C41 board is working well. My set spindle RPM will stabilize with in 1 RPM of actual if I get it 10 or 15 seconds. Started messing around with threading last night. Lots of stuff to play with there, but seems to work as advertised so far.

Here is a photo I found of my first CNC lathe setup G0704 style from a while ago.

-

03-17-2013, 05:57 AM #50Albert586 Guest

I started working on my tool post mount last night.

-

03-17-2013, 07:36 PM #51

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Constant Surface Speed test turning a half sphere 1.618" dia

http://www.youtube.com/watch?v=BwLBW...ature=youtu.be

-

03-18-2013, 03:08 AM #52

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Here is a quick video showing Mach turn and my iMachIII P1A-S pendant as it applies to the lathe.

http://www.youtube.com/watch?v=KSaUB...ature=youtu.be

-

03-18-2013, 03:27 AM #53

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Here is a quick test of backlash in Z on the G0602 CNC conversion using Billys kit. I measured .0009" backlash as you can see in the video. I am happy with that. As the ball screw wears in this will probably loosen up a bit more.

http://www.youtube.com/watch?v=CbpA1...ature=youtu.be

-

03-18-2013, 03:01 PM #54

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Here is a little discussion regarding the CNC4PC C6 board output voltage issues. Sounds similar to what I saw.

http://www.machsupport.com/forum/ind...c,10185.0.html

I replaced my C6 with a C41 board and it is working fine.

-

03-18-2013, 03:27 PM #55

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 101

You are going to cause me to spend money I don't really have.

-

03-18-2013, 04:11 PM #56

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

-

03-19-2013, 03:30 AM #57

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Messing around. Ball screw covers.

-

03-19-2013, 02:30 PM #58

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

The finish you're getting with that machine is beautiful! Where did you get that indexable toolholder? I've been looking for something like that.

Regards,

Ray L.

-

03-20-2013, 05:29 AM #59

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Ray,

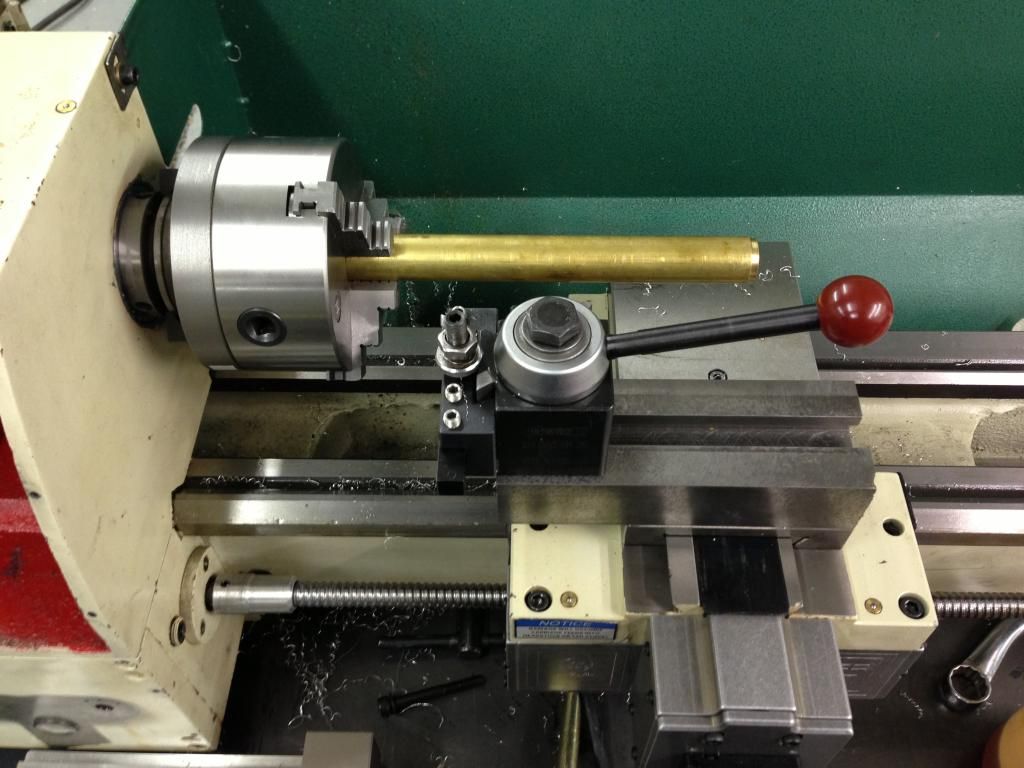

The Indexable tool holder I use is a Phase II AXA wedge style. I got mine from Enco.

Here is the catalog page.

http://www.use-enco.com/CGI/INPDFF?P...MITEM=890-9636

I think the web price is around $187 some times you can get 10% off and free shipping as well.

Enco also sells an AXA set made by Aloris that is probably a little better quality but more money.

Enco also sells a phase II piston type that's a little cheaper, I believe the wedge type are generally considered a little more repeatable.

CDCO

http://www.cdcotools.com/

Also sells a wedge and piston type AXA tool post set that looks pretty good for under $100.

Here is the 1/2" Indexable Carbide Turning Tool Set I have been using in the videos.

Shars

http://www.shars.com

http://www.shars.com/products/view/2...rning_Tool_Set

-

03-20-2013, 06:03 AM #60

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

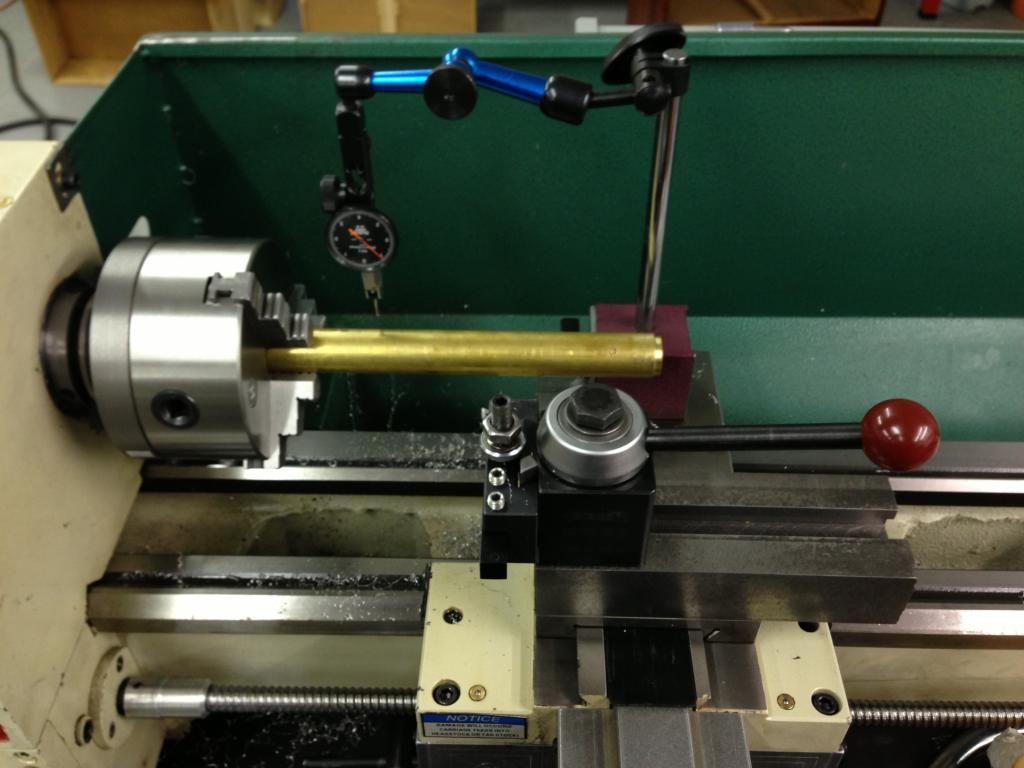

Today my friend brought over the tool post mount we discussed a few days ago. This is machined out of fairly hard chunk of cast iron. He said he had about 2.5 hours into it. He squared it up and cut the t-slots for me to use. The ends are sawed off. I need to machine a T-nut yet and drill a few countersunk mounting holes in the bottom of the T-slot. I will also flatten both ends. He machined this on a big CNC that came out of Boeing in Seattle. It will have the option of forward or back mounting as seen in the photos. I thanked him a lot! BYE BYE original G0602 compound!!!!

Similar Threads

-

Grizzly G0602 10" x 22" Lathe Conversion

By derekbackus in forum Vertical Mill, Lathe Project LogReplies: 145Last Post: 01-29-2019, 09:29 PM -

King 10x22/Grizzly G0602 CNC conversion with full enclosure

By ZincBoy in forum Vertical Mill, Lathe Project LogReplies: 5Last Post: 01-16-2013, 08:35 PM -

Grizzly's G0602 10x22 Lathe

By cobmachine in forum Benchtop MachinesReplies: 21Last Post: 02-01-2011, 03:26 AM -

Grizzly G0602 10x22 Lathe Conversion

By Steelpolish in forum Vertical Mill, Lathe Project LogReplies: 56Last Post: 01-21-2011, 11:04 AM -

About to pull the trigger on a Grizzly G0602

By akschu in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 08-28-2008, 09:36 PM

Reply With Quote

Reply With Quote