I have been chasing ball screw and ball nut issues for the past 2-3 months and I have bought them all from Chai. My advice would be to buy the entire assembly together so you know it fits right from the start. I have three "identical" nuts and three "identical" 1605 screws and I am not able to mix and match the components freely with ball sizes ranging from .1225, .1230, .1235, .1240, and .1245. The screws can come severely undersized/oversized and so can the nuts so the only way to know you are going to have a working combo is to either buy it assembled or make sure you have a bunch of different ball sizes so that you can pack it until it spins on.

If the nut doesn't thread on you need to either switch to a smaller ball size or check to make sure there aren't any balls stuck in the little spot between the circuits.

Good luck!

Thread: Zach's G0704

Results 41 to 60 of 155

-

03-26-2013, 04:30 PM #41

Registered

Registered

- Join Date

- Feb 2012

- Posts

- 296

-

03-26-2013, 04:57 PM #42

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

Sadly I didn't think of this before I purchased them... Do you know where I can find balls smaller than .1237? So far I haven't had any luck, and to compensate for a .017 difference in screw diameters I don't think that will be small enough. I don't mind if there is a little play/backlash in the nut, as it is only going to be used for preloading purposes.

-

03-26-2013, 05:04 PM #43

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

3mm balls might be my best bet. They are .118 dia. Worse case I'm out $10 and have to get a new nut. They would be .007 under, which would make a .014 difference I would think, so even they may not be small enough.

-

03-26-2013, 05:24 PM #44

Registered

Registered

- Join Date

- Feb 2012

- Posts

- 296

The vendor "toolsupply" on eBay has a bunch of sizes available, that's where I got mine.

-

03-26-2013, 06:20 PM #45

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

The smallest I saw he had was .1237. vxb bearings had 3mm balls pretty cheap.

-

03-26-2013, 08:17 PM #46

Registered

Registered

- Join Date

- Feb 2012

- Posts

- 296

I bought those .1237 balls and they came to me as .1225, every single one of them, so it might be worth contacting him to see if he has any sizes that aren't currently listed.

So he sent me the wrong item but they still weren't small enough for me to use.

What method are you using to pack them?

-

04-08-2013, 02:33 AM #47

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

I've done a little more work, but a considerable amount of it is machining. The parts are pretty well made for the X and Y axes, just a couple pieces for the Z to go and it should all bolt together. Almost all of the castings have been modified as needed, with the exclusion of the base, which should be done in a week or so.

The base is pretty well done. I've attached legs and casters, added some cross supports, filled with sand, and welded it up. Amazingly, it rolls on all four casters nicely. It weighs about 250 lbs as it sits.

I also fit together the table and saddle. The 3mm balls I got to attempt to match the different ballscrews to nuts worked perfectly, if anything they were a little bit tighter than the other ones. I had to free up the dust seals a little bit to get them to roll properly, but there is no perceivable backlash now. Packing the ballnuts was far easier than I expected.

There is quite a lot of progress happening, its just all behind the scenes. Electronics are coming together nicely, and I will post a little about the setup shortly. Once I get the ways fitted and a couple of aluminum pieces machined, it will be a short time till its up an running!

-

04-08-2013, 05:07 AM #48

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 962

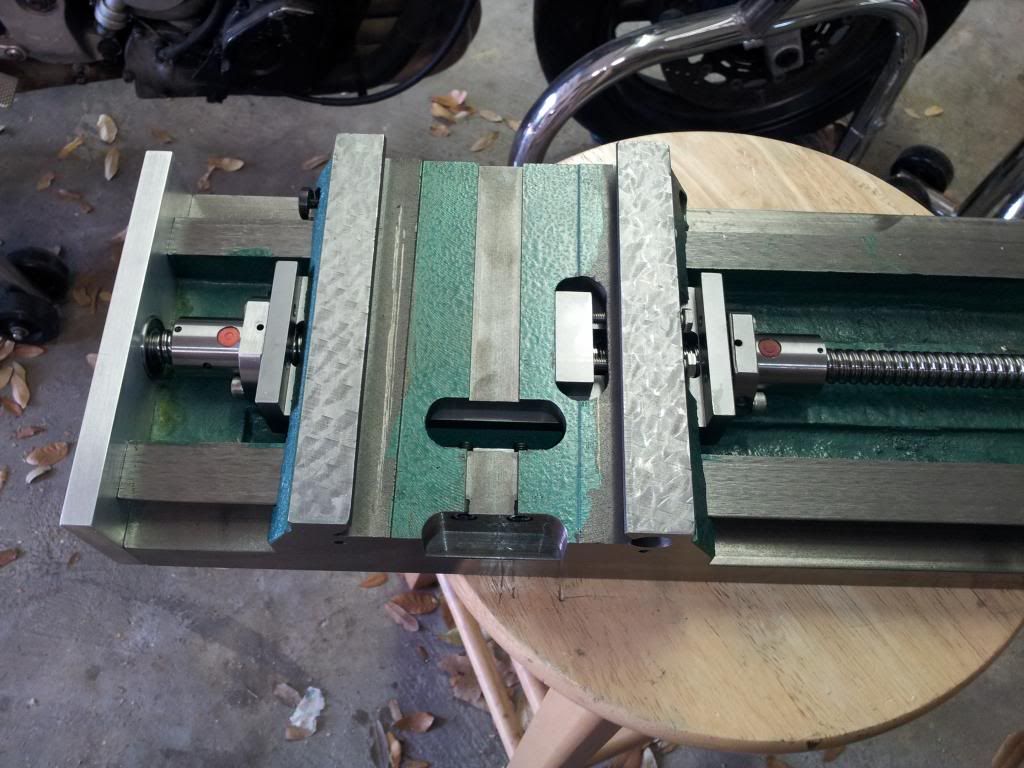

Unless I over looked the explanation, it appears to me you're giving up a fair amount of X-travel with the ball nuts mounted outside the saddle as shown in your picture?

-

04-08-2013, 04:23 PM #49

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

Yes, that will cost me about 3" of travel. I discussed this in another thread, but the only other way to use double nuts involves cutting far more than I like out of the saddle. The saddle is flimsy enough as is, and cutting two pockets on either side to clear the ballnuts would only worsen it. This way I lose travel, but it should be far more rigid and easier to preload as I can use 4 screws per side instead of two. The remaining 15" of travel should be enough. I know there will be times when I wish I had a little more travel, but that will always occur. It happens on the bridgeport I run quite often. However, 90% of the work will be in a 6" cube in the middle of the table. My goal is to hold .002 in that area, so the increased rigidity is a must.

-

04-08-2013, 11:05 PM #50

Gold Member

Gold Member

- Join Date

- Aug 2010

- Posts

- 630

You should be able to get .002 with the single Ball nut if not better. I see little point in double ball nuts on these machines. Too many other factors are going to cause backlash / deflection besides the ball screws and nuts. As for the amount you would have need to mill of to mount them the other way. I don't think it would have compromised the saddle that much.

Inner Vision Development Corp. - http://www.ivdc.com

Website Design & Development. Shopping Carts, SEO and more!

-

04-09-2013, 12:29 AM #51

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

For the cost of a second ballnut, might as well use it. If it rids a thou of backlash, then at least that a thou less than before. I know that column flex is probably going to be the biggest cause of inaccuracy, but might as well minimize it if you can. I hope .002 or even .001 is doable, peoples opinions on here seem to vary quite a bit. Some say you're lucky to get .005, others seem to be doing much better. Guess I'll find out soon enough.

-

04-09-2013, 01:21 AM #52

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

I ended up skimming just a tiny bit off the bottom of the table, just to remove a few casting irregularities. I probably took .050 off max. I really did not want to take the vice off the table, so I ended up just hanging it over the edge. I cut one side then flipped it around and cut the other. When I was at max travel there was less than an inch left uncut in the middle :tired: So I had to flip it around and do a 3rd cut. Still faster than taking the vice off...

Also, I picked up an electronic box. It was designed for phone, coax, and home alarms. It didn't give any dimensions on the box, so I assumed it would be about the same size as the box. Turns out it was about half the thickness of the packaging, or 3.5" thick. I should have realized this, since it is designed to mount flush in a standard all, and 2x4's are only 3.5 wide. Anyway, everything would have fit, with the CPU heatsink shown being the tallest part, but I found a decent deal on an 18X24X6 industrial box on ebay. It also has a whole lot less holes (none actually), which is a plus since I'm trying to make it water resistant. Here's the old box:

Other than that, I'm looking to start lapping/scraping the machine soon. Where is the best place to get lapping compound?

-

05-05-2013, 12:29 AM #53

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

As much as I'd love to post an update, my home network has been having issues accessing the 'zone. The DNS lookup is failing for this site only, and won't connect, regardless of what computer I use or what my DNS settings are. ISP says I have a bad modem, we'll see if that fixes it. I have a post written up, I'll get it up when I can get on this site again.

-

05-06-2013, 08:06 PM #54

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

Two weeks since an update and I wish there was more to talk about. Here's what I got:

I attached some threaded studs to the table, this will allow me to bolt on the base of the machine. They all line up fairly well, and the base lies relatively flat. I'll probably use some HDPE rubber to offset the base from the table just to account for any mismatch when mounting. I don't want to warp the base when I tighten it down.

New big electronics box mounted. I added a rail to mount it with ease. It's closer to the control panel on this side of the machine.

[IMG]http://i1161.photobucket.com/albums/q513/zamazz10/2013-04-

14160150_zps28836438.jpg[/IMG]

Threw some of the electronics in the box. Still need the Mesa board, some relays, etc, but I should have plenty of room.

Here's the reason I need an enclosure... I was making a few steel parts for the machine and things got messy. There were chips 30 feet across the shop...

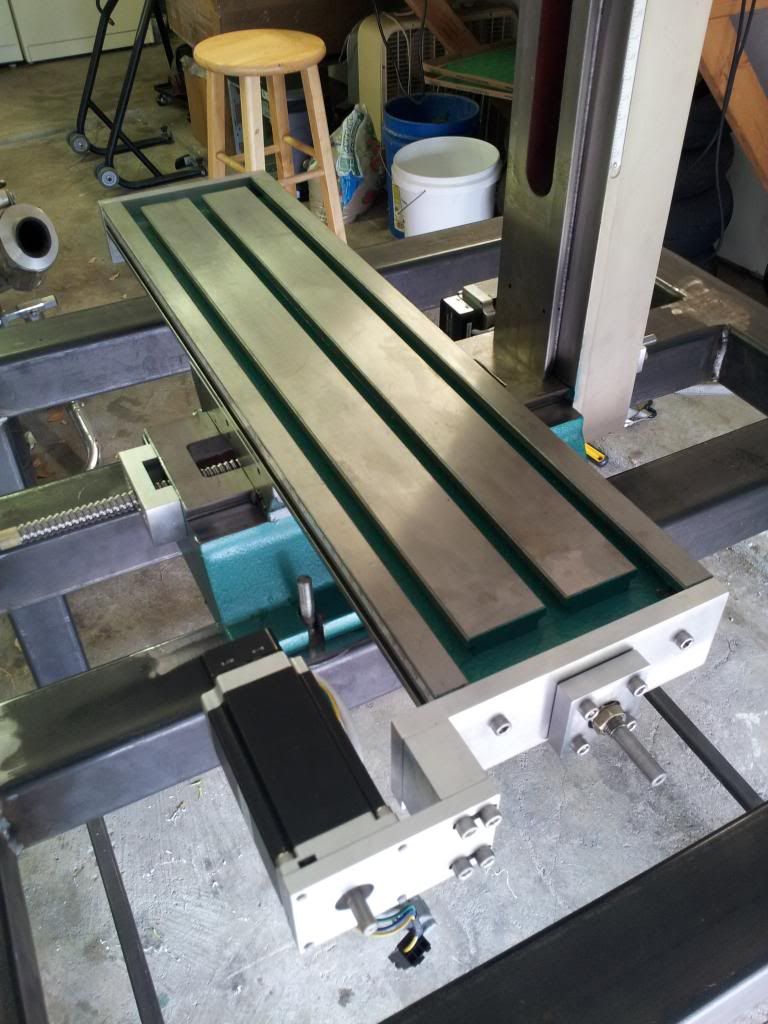

Some preliminary assembly of the machine. Took about two hours to assemble, all for the sake of seeing how it looked. It seems like I'm almost there, but then I realize I have a long ways to go. School will be out in a week and a half though, then I intend to take some time off and get her finished!

-

05-06-2013, 08:46 PM #55

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

I FINALLY got that to load on my phone, after it broke two computers. I tried on a school computer and it had the same effect as in mine. I can't access the zone on the school computer now. Its strange...

-

05-08-2013, 09:20 PM #56

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 32

I just took delivery of a g0704 mill that I was going to cnc and it was the same thing, the dovetail on the vertical column, both sides and on the right hand side of the base were unground. It has taken two weeks, and I had to get my wife involved as she is a sales person and can really talk people into stuff, to get a response and get them to send me another mill - i'm really upset with Grizzly as I had such high hopes for this project and so many people have had good results.

-

05-08-2013, 09:22 PM #57

Gold Member

Gold Member

- Join Date

- Aug 2010

- Posts

- 630

You take pictures of it? I'm curious to see what you all are talking about...

Inner Vision Development Corp. - http://www.ivdc.com

Website Design & Development. Shopping Carts, SEO and more!

-

05-08-2013, 09:30 PM #58

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 32

I did as the tech department wouldn't entertain anything without evidence. I will find them and post.

Attachment 184040

Attachment 184042

Attachment 184044

Attachment 184046

Attachment 184048

Attachment 184050

Attachment 184052

The pin on the fine feed also just popped out each time you turned the handle, almost irrelevant but I thought one more piece of evidence for a poorly put together machine. I almost forgot, the bearings made noise and the motor ran hot, need I go on?! Parts of the ways were rougher than some of the files I have in my box.

-

05-08-2013, 10:22 PM #59

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 32

Pictures included.

-

05-08-2013, 10:58 PM #60

Registered

Registered

- Join Date

- Feb 2013

- Posts

- 164

They were rather uncooperative with me as well. If qc issues like this persist, there's no way I'd recommend this mill. Of course, there aren't a lot of options for the price.

Similar Threads

-

DRO for G0704

By UMR in forum Benchtop MachinesReplies: 4Last Post: 07-06-2016, 04:04 AM -

No Joy with my New G0704

By DogWood in forum Benchtop MachinesReplies: 5Last Post: 07-05-2016, 05:49 PM -

Zach's Homebrew CNC Mill

By Zach_G in forum Vertical Mill, Lathe Project LogReplies: 76Last Post: 06-27-2015, 04:28 AM -

G0704... Yes Another One ;)

By ww_kayak in forum Benchtop MachinesReplies: 24Last Post: 05-27-2013, 03:47 PM -

G0704 or a X-3

By USN in forum Benchtop MachinesReplies: 8Last Post: 05-30-2011, 08:24 AM

Reply With Quote

Reply With Quote