Hi folks. I have lurked around here for a couple of years reading all that I could about CNCs. At first I thought I would build one and after watching so many people spend so much time and money on their first machines with mixed results I decided to search for a new machine for my needs.

What I wanted:

1. At least 24" by 36" by 7" work envelope

2. Extremely rigid for superior finish quality

3. Must have a spindle for precision (and quiet)

4. Ease of use

I looked at all the machines I could. I had a friend that had a another machine that I prototyped some work with but the finish quality was not that great and it could not perform cuts into solid wood and produce smooth, chatter free edges. Even at very slow feed rates the bits chattered due to the insufficient gantry supports.

Then I visted Carl Bruce in Bremerton, WA. I tested his machine and it was light years ahead of anything else I tested. The reason I went with Carl are: overbuilt design, came with a spindle, local business, and excellent support and reputation, and of all the cuts were finish quality right off the machine.

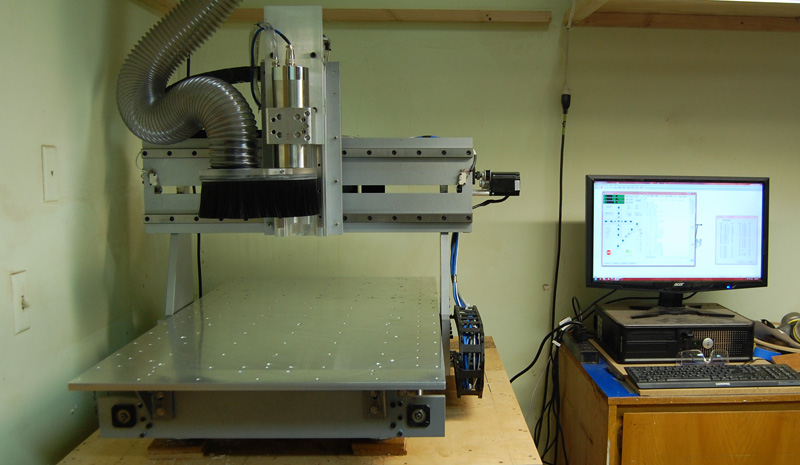

Here are the specs:

25" x 36" x 7.5" work area

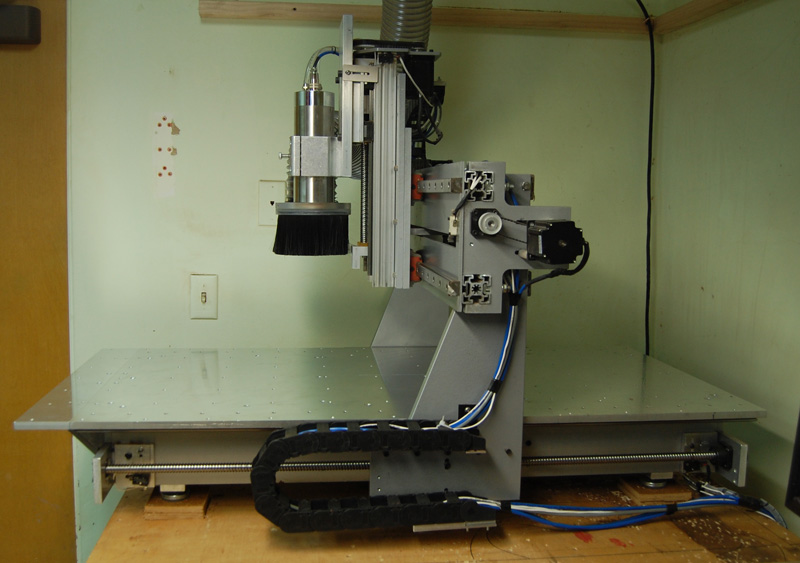

Dual x drives for ultra rigid gantry

Precision ballscrews and hiwin linear rails and bearings on all axis

Built with 1/2 and 3/4 6061 aluminum

Cast aluminum milled Mic-6 deck drilled and tapped for hold down

400ipm cut speeds and rapids,

Water cooled 2.2 kw[3hp] spindle,VFD,and cooling system.

Price: $6600

Carl Bruce: [email protected]

Here are some photos:

Cutting a Claro Walnut carved top:

Parallel finishing at 8-percent offset 0.03" from perimeter edge followed by a pencil tracing pass to clean up the edges.

This is the first cut I made. It took a couple swipes with 220grit to clean it up. Spiral machining cut at 8-percent stepover with a 0.50" spiral ball nose bit.

These cuts are being made at about 230ipm with a total cut time of 25 minutes. I pushed it to 300ipm for the first cut to see what it can do and it seemed to run fine but dropping it below 250ipm stopped some low end motor noise. It was really moving!~ My goal here is precision and finish quality, not speed. Still, this used to take me nearly 2 days by hand using a duplicarver and orbital sander to shape the top, and all manner of hand tools cutting and fitting braces. And the sanding time is negligible now.

This is my first week with the machine but I have been preparing. For the last 2 years I have been learning CAD and developing my 3D models in Rhino. And I have spent about 2 months with RhinoCAM simulating tool paths getting ready for the machine's arrival last week. I was able to cut a part immediately and have all of my singlecut carved top shapes done so far. The rest of this week and next I am going to develop my fixtures and machine code for guitar necks. That's where the real time savings is going to come.

Controller software is Dynomotion using the KFlop boards and drivers. USB connection is fast and no interruptions. I can run Rhino while the machine is running if I want to. I don't but I could. Great software. Easy to configure, and easy to operate. I have a background in programming so that probably helps.

I hope that this post helps anyone looking for a machine that will cut guitar parts with precision and quality. It's the best machine I have tried by a long shot. That's why I bought one.

~David

Results 1 to 12 of 12

-

08-01-2012, 06:57 PM #1

Member

Member

- Join Date

- Mar 2011

- Posts

- 6

New CNC (for guitars) made by Carl Bruce

-

08-01-2012, 08:40 PM #2

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1268

Looking Good David!

I'm just entering into guitar building and look forward to future posts with your accomplishments.

Billbillyjack

Helicopter def. = Bunch of spare parts flying in close formation! USAF 1974 ;>)

-

08-01-2012, 09:35 PM #3

Member

Member

- Join Date

- Mar 2011

- Posts

- 6

I also wanted to point out a cool feature. The front 5" of the table is removable so that a piece can be clamped on end for doing guitar neck (or furniture) dovetails, end tenoning, drilling, etc. A very nice detail!~

~David

-

04-18-2013, 12:59 AM #4

Member

Member

- Join Date

- Jan 2007

- Posts

- 1795

hiwin (or other brand) square rails and double ballscrew on X says everything..

i also like the belt between motor and screw.. with a gear ratio you can double the speed.. yet its very precise..

-

08-27-2014, 08:31 AM #5

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 25

Re: New CNC (for guitars) made by Carl Bruce

would love to see some finished guitars

-

08-31-2014, 08:58 PM #6

Member

Member

- Join Date

- Mar 2011

- Posts

- 6

Re: New CNC (for guitars) made by Carl Bruce

I have built many parts and full guitars with this CNC machine now. I am continually blown away by how well this machine performs. Carl could easily charge double and it would still be a bargain,

Here are some photos of completed guitars made on this machine:

Attachment 247880

Dragonfly #156

Dragonfly #155

Attachment 247870

Custom Archtop #160

Attachment 247872

Extreme Custom #172

And some design work in Rhino: Greg Hurley - Custom #172

And some inlay details:

Attachment 247874

Attachment 247876

Just an insane machine!~

~David

-

09-01-2014, 01:59 AM #7

Member

Member

- Join Date

- Jan 2007

- Posts

- 1795

Re: New CNC (for guitars) made by Carl Bruce

those inlays are masterpieces...

-

09-01-2014, 11:01 AM #8

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 25

Re: New CNC (for guitars) made by Carl Bruce

yeah !

very cool guitars, love the dragonfly design ... and the multiscale archtop looks interesting as well. i'm starting my first build soon, have bought all the ingredients and design is finished and modeled in Rhino ... but the cnc is acting up at the moment, as soon as that's sorted i'm finally getting at it

thx for the pics .. . keep it up !

-

11-21-2014, 08:31 PM #9

Registered

Registered

- Join Date

- Nov 2014

- Posts

- 3

Re: New CNC (for guitars) made by Carl Bruce

Is this person still building this machine? I did send an email to the address in the original post. I am really interested in getting more information regarding this machine. currently I have been looking at the Laguna tools IQ second-generation router. Maybe a website for the builder? Thank you in advance

-

11-21-2014, 09:16 PM #10

Member

Member

- Join Date

- Mar 2011

- Posts

- 6

Re: New CNC (for guitars) made by Carl Bruce

mschribes, yes Carl Bruce is still building these. And they are getting better all the time.

Carl's last email to me is using this addess: [email protected]

I am still using this machine nearly every day and it never disappoints. Amazing precision and productivity. Love it!~

~David

-

03-29-2015, 04:28 PM #11

Registered

Registered

- Join Date

- Oct 2014

- Posts

- 6

Re: New CNC (for guitars) made by Carl Bruce

Very cool, I would like to build my own guitar.

Does someone know where I can get the drawings etc?

-

03-30-2015, 04:32 PM #12

Member

Member

- Join Date

- Mar 2011

- Posts

- 6

Re: New CNC (for guitars) made by Carl Bruce

Hi scalci,

Drawings for my instruments? You can't. You can find generic drawings of Strats and Les Pauls all over the net.

Your best bet would be to design a guitar from scratch in CAD. Otherwise you really don't know what you are building. It's the same as every other worthwhile endeavor.

The latest from the bench:

Attachment 274832

~David

Similar Threads

-

Carl Zeiss CMM

By Baronas in forum Calibration / MeasurementReplies: 0Last Post: 11-27-2013, 10:42 AM -

Autodesk CEO Carl Bass Thinks The Future Of Hardware Startups Extends To The Moon And

By cncadmin in forum 3D Printer / 3D Scanner DiscussionReplies: 0Last Post: 10-19-2013, 01:30 AM -

Carl Zeiss Toolmakers microscope?

By Jack F in forum MetallurgyReplies: 2Last Post: 11-01-2010, 03:32 PM -

Looking for Bruce!

By kentrob11 in forum Community Club HouseReplies: 3Last Post: 03-16-2008, 07:53 PM -

Carl's Bridge Mill/Router

By DDM in forum CNC Wood Router Project LogReplies: 15Last Post: 12-31-2006, 06:30 AM

Reply With Quote

Reply With Quote