Hi everyone!

I've always loved CNC machines, and while I have done a more practical conversion in the past, I've always wanted to convert a mill for fun, without any real goal other than building something awesome. I've chosen to start with a g0704 because it is capable but also fairly small and light.

This build is going to be my pet project for a while and I'll do my best to turn my g0704 into a fully featured and polished cnc conversion.

This is my preliminary todo list for the first stage of my conversion:

- Check the machines accuracy and scrape as necessary

- Double preloaded ballnuts on all axes

- Servos

- Glass Encoders on all axes

- Fourth/Fifth Axis

- Extended Travels

- Automatic Oiler

- Stand that integrates column support

I will be paying special attention to how several of the mods are performed (5th axis, extended travels) to ensure rigidity and accuracy are not compromised.

I am cheating a bit with my buildlog as I started this conversion a few months ago. I didn't have as much time back then and the work was more repetitive though so this just lets me keep the thread interesting.

Anyways, I've been reading about scraping and I picked up a copy of machine tool reconditioning so the first step is to make a straightedge. I am going to have to warn everyone I've never done this before and I really don't know what I am doing. The process seems logical enough though.

I started with a 2' length of cast iron bar.

Unfortunately, a 16" straightedge was at the absolute limits of my current mills travel and I needed to be very creative to get it cut. Going all the way to the ends of my travel wrecked the accuracy and the surfaces are convex by about 5 thou.

I quickly discovered it would be very tedious to scrape that flat by hand so I cheated and used an orbital sander + dremel to get it somewhat flat.

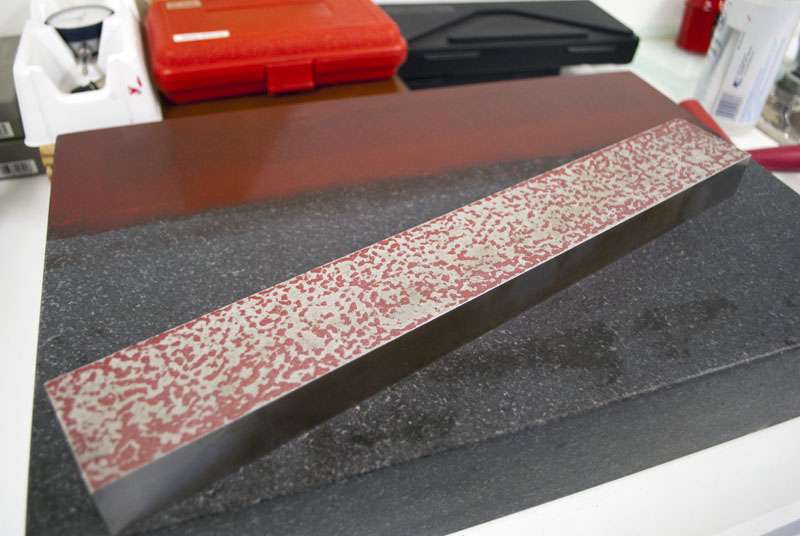

Spots alright, but the dremel does leave some pretty deep scratches. Not really something you are supposed to do, but the results seem okay.

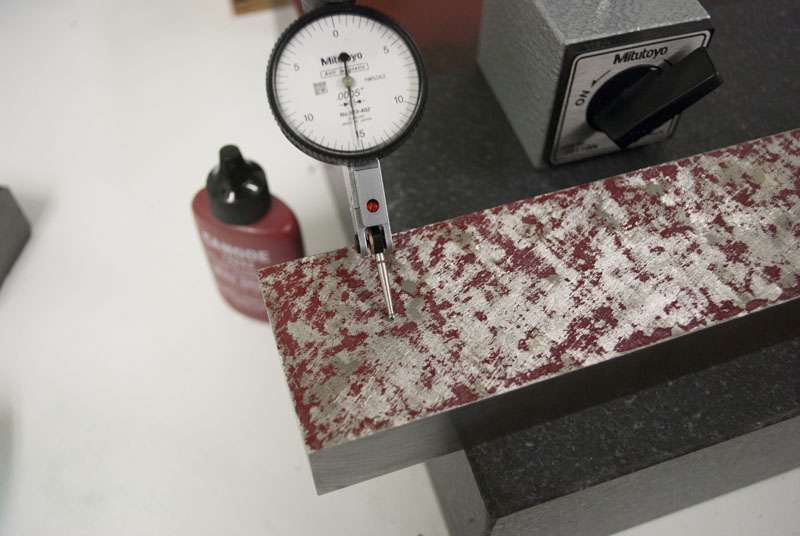

I checked the dremeled surface with an indicator, the bumps are about 0.3 thou above the low spots.

And properly scraped, I had to remove a fair deal more material to get it to spot nicely without scratches.

I left the straightedge fairly flat but not entirely finished, I spent two and a half days scraping the thing and I won't actually have that many uses for it.

Thread: Ryan's g0704...

Results 1 to 20 of 284

Threaded View

-

07-01-2012, 06:02 AM #1

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 419

Ryan's g0704...

Similar Threads

-

G0704

By kd4gij in forum Benchtop MachinesReplies: 8Last Post: 07-07-2016, 12:00 AM -

DRO for G0704

By UMR in forum Benchtop MachinesReplies: 4Last Post: 07-06-2016, 04:04 AM -

No Joy with my New G0704

By DogWood in forum Benchtop MachinesReplies: 5Last Post: 07-05-2016, 05:49 PM -

G0704... Yes Another One ;)

By ww_kayak in forum Benchtop MachinesReplies: 24Last Post: 05-27-2013, 03:47 PM -

G0704 or a X-3

By USN in forum Benchtop MachinesReplies: 8Last Post: 05-30-2011, 08:24 AM

Reply With Quote

Reply With Quote