I have this problem still to be solved...anyone did this in the past? Should I have to disassemble the entire Z axis column? Thanks in advance

Results 1 to 7 of 7

-

03-29-2012, 12:43 AM #1

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 28

Replacing broken coupling on Z axis (X4 Plus)?

gtcknives.com

-

03-29-2012, 06:32 AM #2

-

03-29-2012, 09:42 AM #3

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 28

Bought in 2008, X4 plus

gtcknives.com

-

03-29-2012, 04:58 PM #4

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 41

Will this drawing help? I haven't replaced the coupler but I've been in there enough! I think all you need to do is; start with the z axis about in the middle - you can put a socket extension through a hole in the top of the column #105 onto the ball screw #94 to turn it (square end to the ball screw), 1) remove the back #87 (I wire it to the flex conduit to keep it out of the way, 2) remove #90, 3) unfasten the coupler, 4) raise the spindle assembly and the ball screw should slip through the hole in the top enough to remove the coupler.

Take a good look though because its been awhile since I've had to adjust my ball screw and I might be missing something.

Groundhog

-

03-29-2012, 10:38 PM #5

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 28

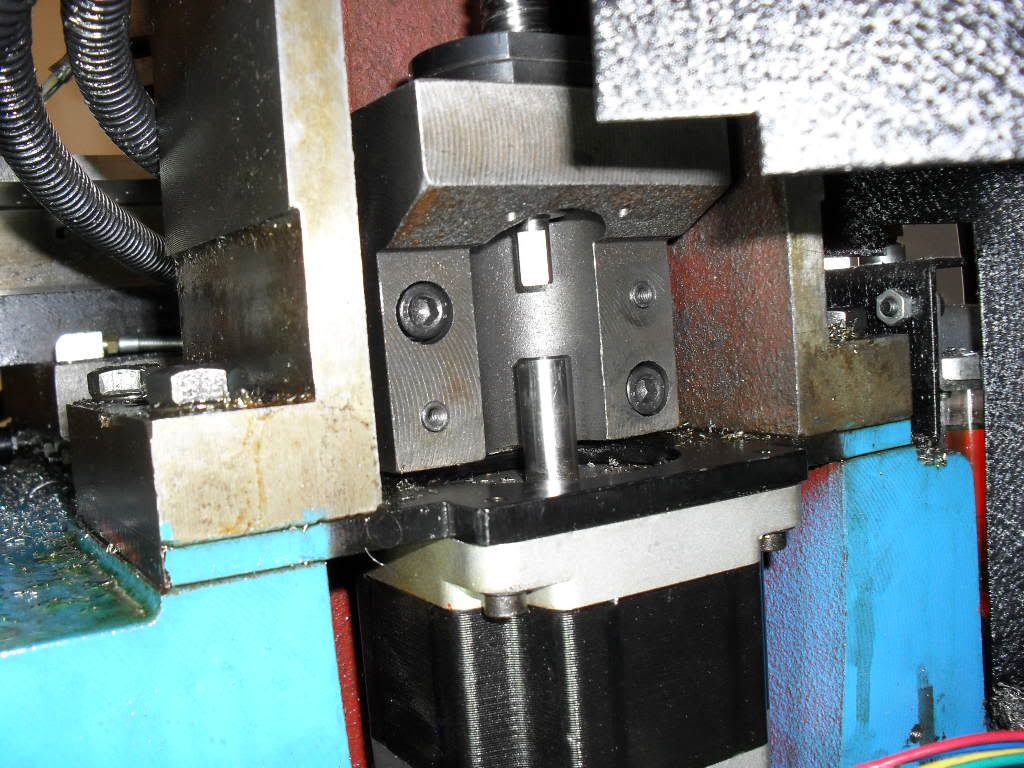

Thanks groudhog for the help but unfortunately I couldn't disassemble those parts, too much wire and not enough space to work. Instead, I built a split coupler and the machine is now working again, see the pics below.

Now Syil people, can someone disassemble the parts like groundhog just said or there's the need of taking off the entire column? I'd love to hear the answer for that.

gtcknives.com

gtcknives.com

-

04-26-2012, 01:25 AM #6

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 839

That split coupler will break the shaft off of your stepper motor if it has no flex to it.

This is the reason for the split type couplers is so they will give enough to keep from working the shaft until it breaks. It takes perfect alignment to run one like you are using and this takes some pretty good equipment to get such aligned this good.

I understand you had to do this because you havnt been able to take the unit apart, but you need to find out how even if it takes doing the whole column or you willl have a motor with no shaft sticking out.

JessGOD Bless, and prayers for all.

-

04-30-2012, 04:37 AM #7

The easiest way to fix a Z axis is with a lovejoy coupler, been there - done that, you slide each part on each side, then put the plastic part and press together, adjust the Allen screws and done!

Good luck!

Pablo● Distribuidor Syil en Argentina ● "www.syil.com.ar" ●

Similar Threads

-

Replacing Y axis Ballscrew/thrust bearings.

By steedspeed in forum Haas MillsReplies: 7Last Post: 06-28-2014, 09:24 AM -

Replacing X-Axis Bearings

By serkanc in forum Linear and Rotary MotionReplies: 0Last Post: 03-06-2011, 12:03 PM -

Rigid Coupling Vs. Flex Coupling

By Johnsnd in forum DIY CNC Router Table MachinesReplies: 10Last Post: 05-30-2009, 03:25 PM -

How can I coupling a stepper motor axis directly to other axis?

By meknik2001 in forum Stepper Motors / DrivesReplies: 4Last Post: 05-08-2008, 07:54 PM -

Z axis beam coupling help

By Chamm128 in forum K2CNCReplies: 1Last Post: 06-05-2007, 10:38 AM

Reply With Quote

Reply With Quote