Lifted from a suppliers website.............

Tool Steel O1 is a medium alloyed oil hardening steel with excellent cutting force and toughness, the excellent dimensional stability reduces distortion and the possibility of cracking during heat treatment.

Supplied in the annealed condition, the precision tolerances minimise additional costly tool room machining.

Ground Flat Stock provides toolmakers with a decarburization free surface, plus a high wear resistance after heat treatment, making it ideal for a multitude of uses and applications: dies, press tools, punches, gauges, cams, jigs, machine knives and marking devices.

Hardness as supplied: 229 Brinell max

Tensile Strength: 45 Tons / sq. in.

Table of Equivalent specifications:

AISI Werk. No. AFNOR British Spec.

O1 1.2510 95 MCWV5 BS4659 BO1

I have 8 holes to tap in 6 plates so that's just 48 holes to do. I will be using the rigid tapping cycle on the mill. I am not chasing time on this job, just need to make sure i don't break the taps so quite happy to run a slower spindle speed if that's what's required.

Thanks

Results 1 to 11 of 11

Hybrid View

-

09-05-2011, 07:29 PM #1

Registered

Registered

- Join Date

- May 2011

- Posts

- 53

-

09-05-2011, 09:39 PM #2

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 443

Thanks for providing the details.

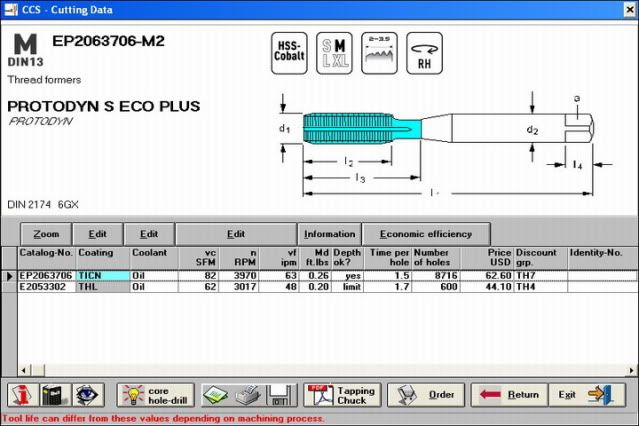

I have the Titex-Prototyp "TEC+CCS 10.2" software installed on my PC, so I ran it for you using all your data. I went with the tighter-tolerance 6G taps to help assure in-tolerance holes after heat-treatment.

First up is the premium roll form tap, a Protodyn S ECO Plus. Note the number of holes predicted per tap. It's a PM (powdered metal) TiCN-coated tap.

Next is the premium spiral flute tap, Paradur ECO-HT with THL (hard-lube) coating. It's also a HSS-Co PM tap.

For the lower number of holes and the fact that you'll be heat-treating the parts after machining, I lean toward the spiral flute tap as it's more-likely going to cut to size. A form tapped hole might have a little more shrinkage at heat treat.

It's list prices in US dollars that are showing. You'd have to contract a distributor in the UK for your pricing.

-

09-07-2011, 07:45 AM #3

Registered

Registered

- Join Date

- May 2011

- Posts

- 53

Thanks for the help and advise, managed to get through this job without any major trauma.

Similar Threads

-

Another machine rigid tapping (stepper machine)

By samco in forum LinuxCNC (formerly EMC2)Replies: 11Last Post: 02-12-2019, 05:53 PM -

Can anyone machine a tooling plate for me?

By Nateg281 in forum Benchtop MachinesReplies: 15Last Post: 06-29-2010, 02:35 AM -

Machine Large Alu Plate for CNC router

By wfung in forum MetalWork DiscussionReplies: 6Last Post: 12-11-2007, 11:07 PM -

Tapping Fine Threads in Copper Plate

By tobyaxis in forum MetalWork DiscussionReplies: 9Last Post: 05-22-2006, 07:27 AM -

tapping head vs hand/cordless tapping machine....

By InspirationTool in forum Uncategorised MetalWorking MachinesReplies: 6Last Post: 09-13-2005, 02:10 AM

Reply With Quote

Reply With Quote