"Is this the design with the bearing ball providnig vibration? How did it work out for you?"

-Yes it worked pretty good but when the molds get bigger you really need a strong vibrator.

"What were your thought about putting the unfinished side of the EG saddle uppermost? I would have thought that the unfinished part of a mould would be better hidden below."

-It would have been nice with a smooth surface on top but the angeled surfaces underneath forced me to do it this way.

"What was the mould material? What mould release agents did you use, did they work well?"

-I don't know what its called in english but its a wood-based board.

I painted it and then waxed the surface but the damn thing wouldn't come loose.. I ended up smashing the mold :tired:

So its a no on the last question

A small note,

Its only the plate between the X and Y axis (or do you say axes?) thats made of E/G

Thread: E/G CNC Mill

Results 41 to 60 of 70

-

12-15-2011, 09:57 PM #41

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

-

12-15-2011, 10:45 PM #42

Registered

Registered

- Join Date

- May 2005

- Posts

- 56

You should try entering this into the cncmentor.com build log competition! Nice work!

http://cncmentor.com - open source sharing community and CAD Library

-

12-15-2011, 11:05 PM #43

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1306

Thanks for the answers.

I think that is the same experience everyone is having, that they need to kill the mould ot get the bits out.Regards,

Mark

-

06-22-2012, 06:21 PM #44

Registered

Registered

- Join Date

- May 2007

- Posts

- 42

that's a nice machine thewho, i'm interested in knowing what size stepper motors you have any Spec would be nice and what kind of travel speeds are you getting ? by the way how much would that saddle along with linear rails, bearings, plate, motor etc. weigh ?

best

sahil

-

08-07-2012, 06:29 PM #45

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

Haven't updated this so often.

Started on the enclosure (it's still not completed..)

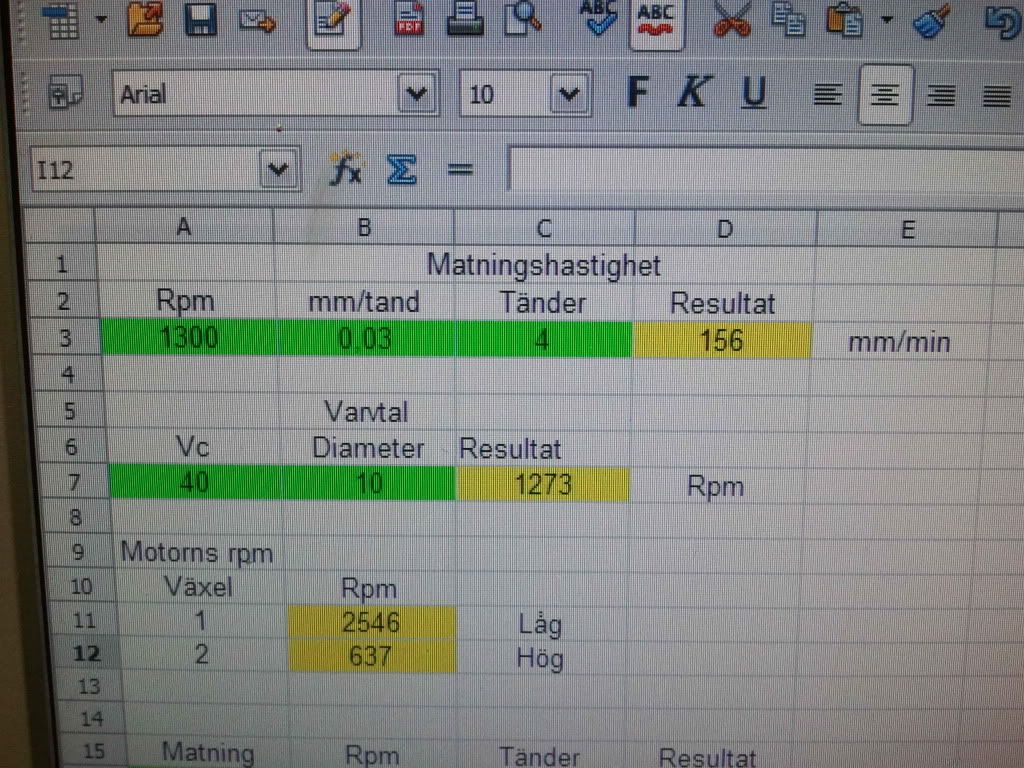

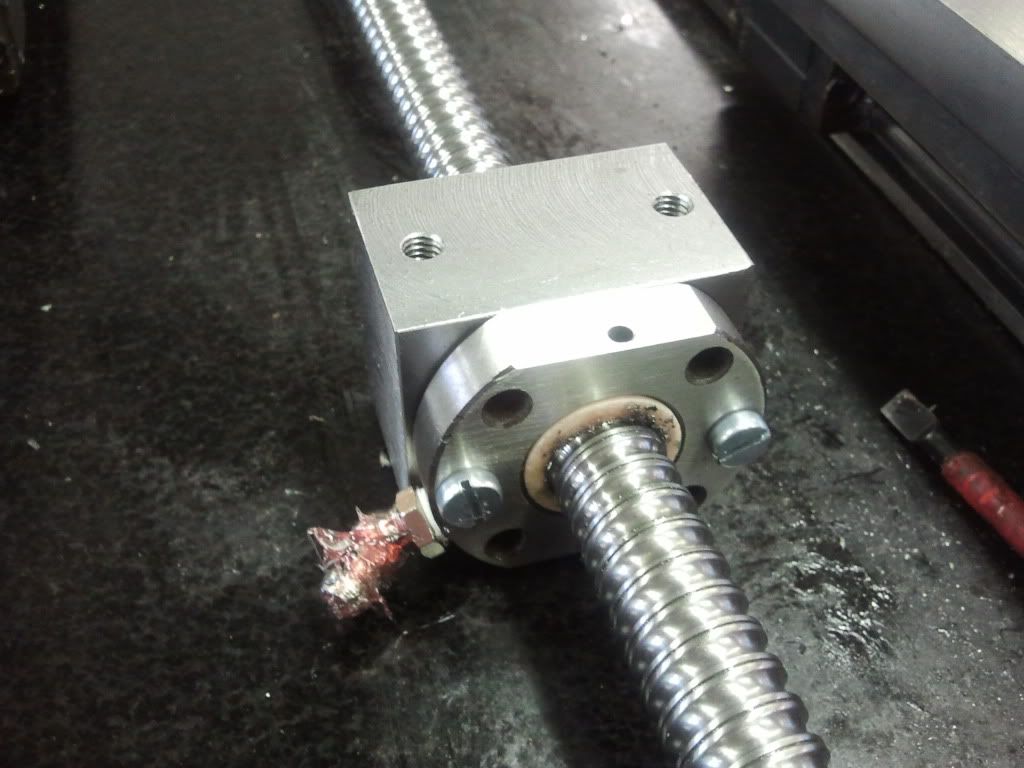

Then I was going to mill a new nutholder(?)

But

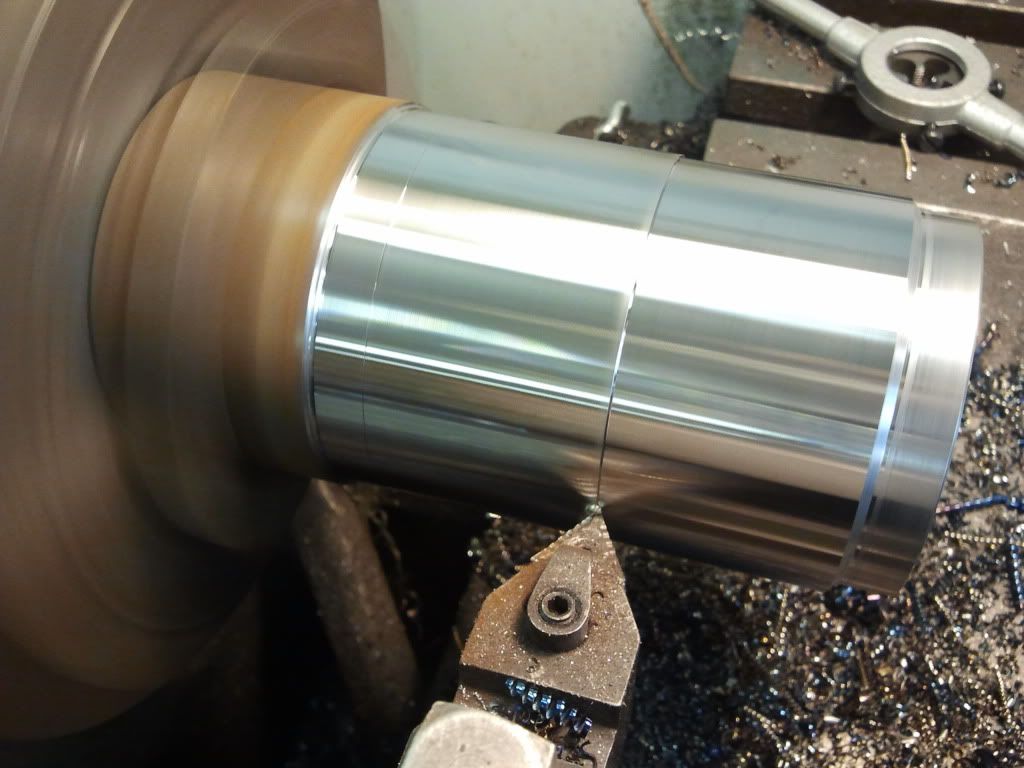

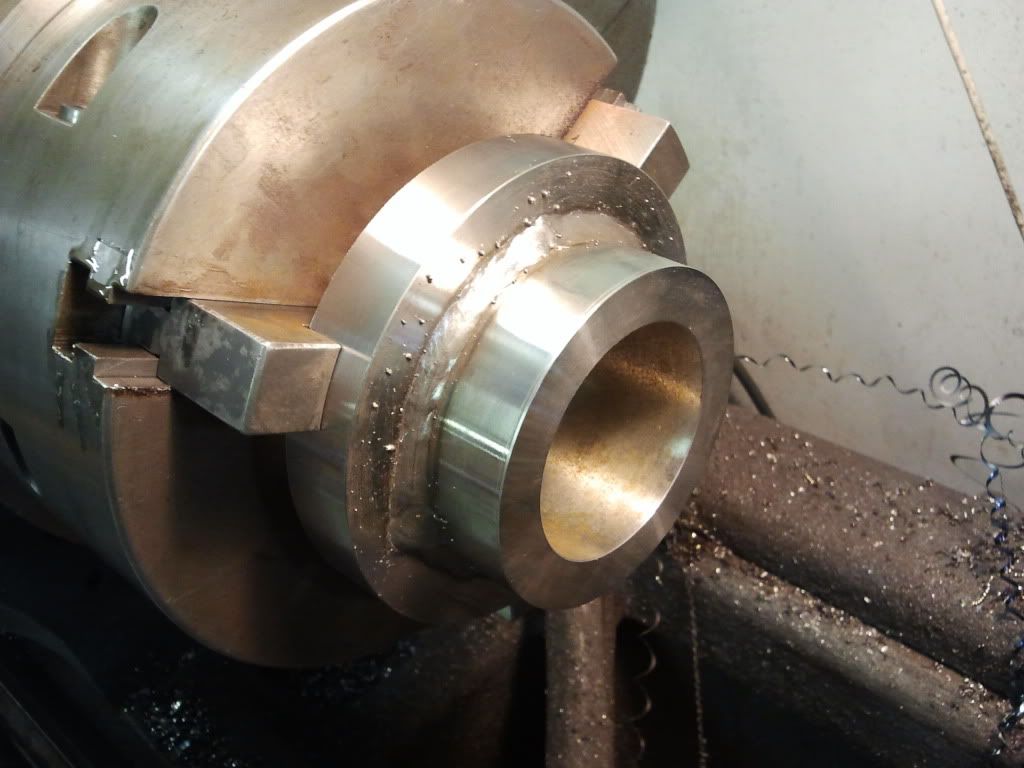

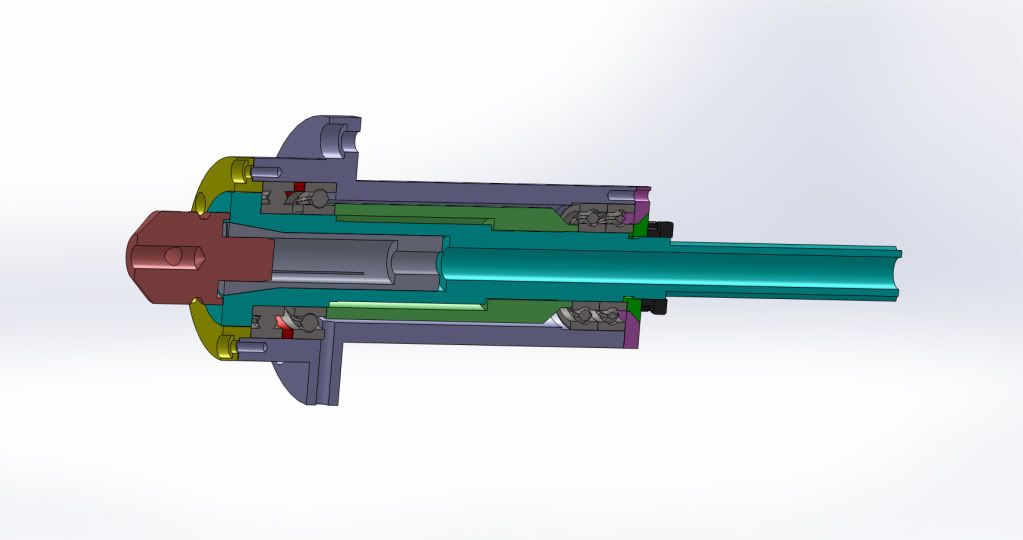

Then I started on a R8 spindle with TTS.

Got my new table.

Ready to use

The old mounts.

Next post will be about the R8 spindle.

-

08-07-2012, 06:38 PM #46

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

-

08-07-2012, 06:40 PM #47

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

There is a lot of pictures on this page..

-

08-07-2012, 06:43 PM #48

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

-

08-07-2012, 06:46 PM #49

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

Hopefully a new page now

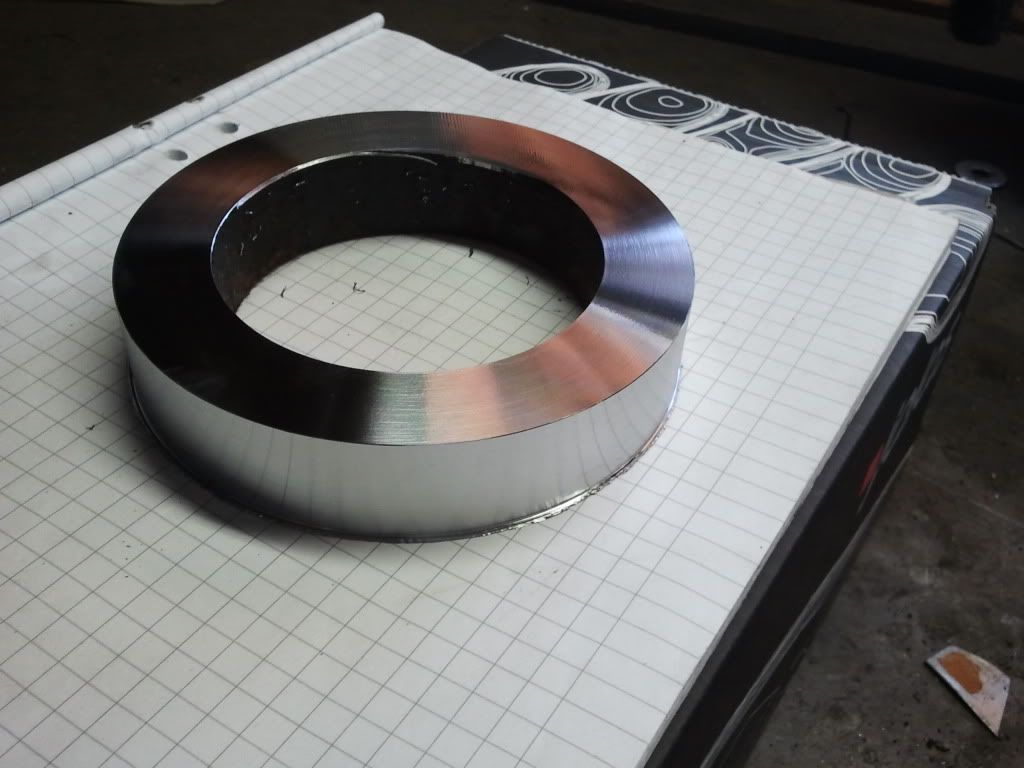

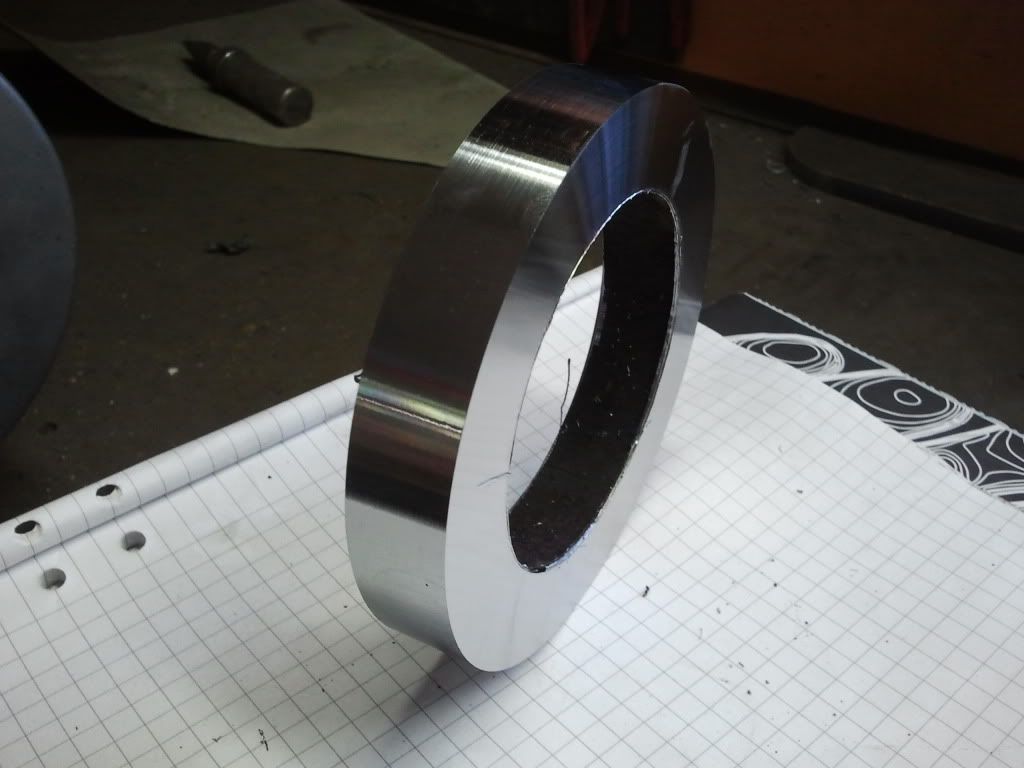

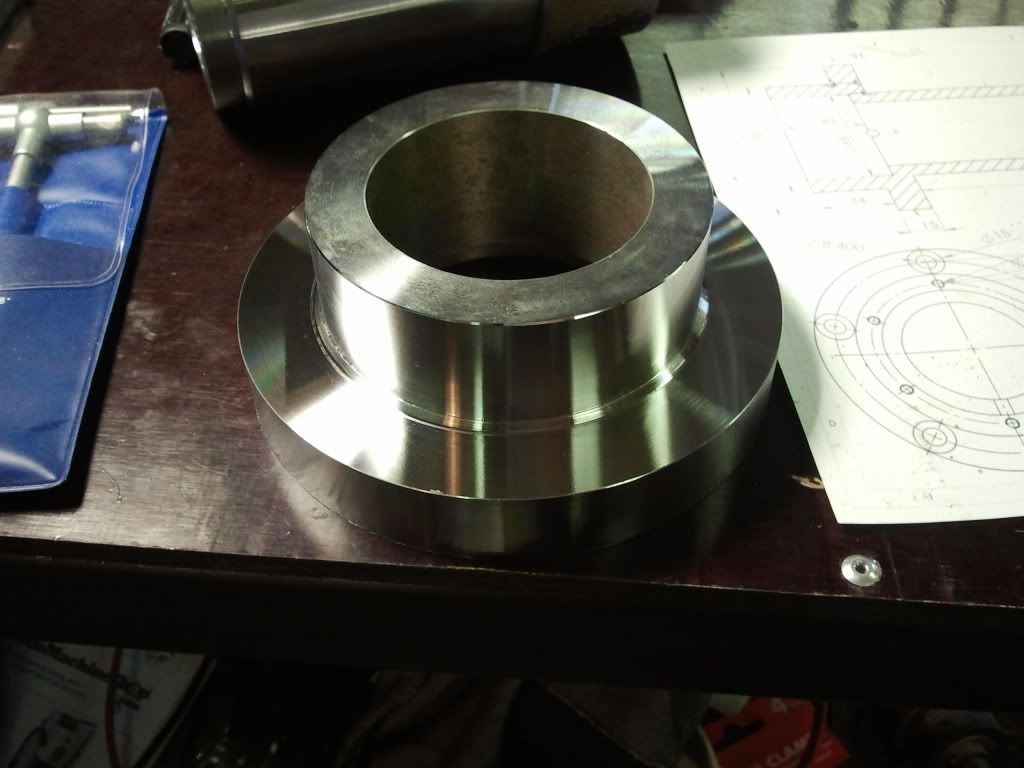

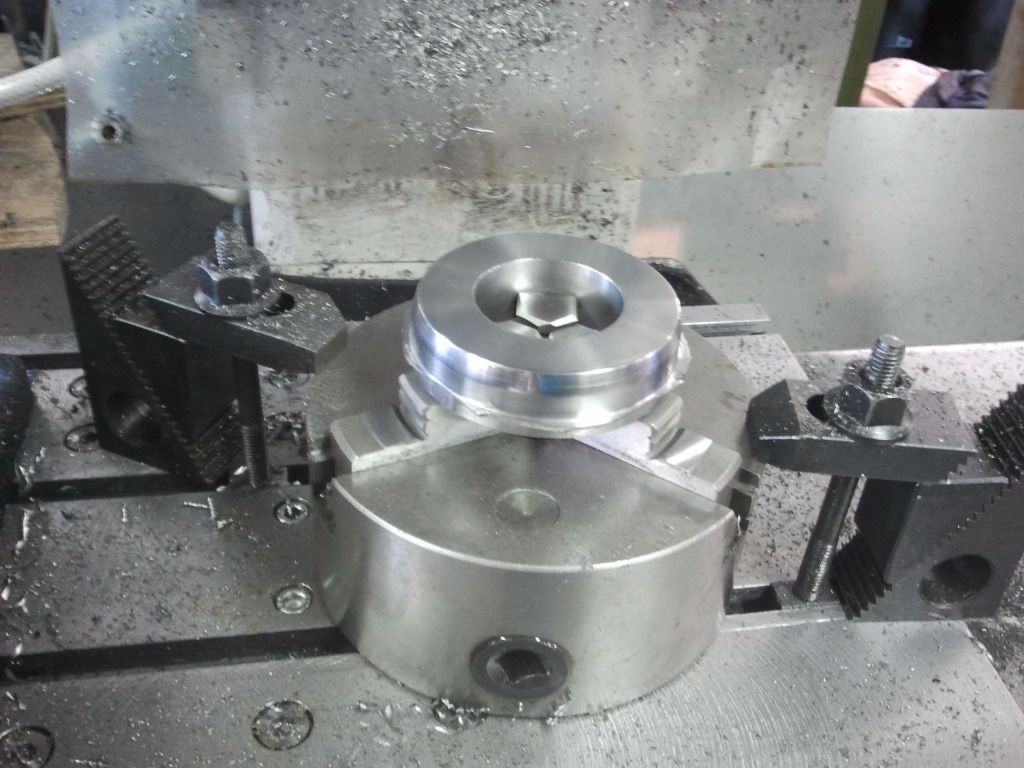

Done!

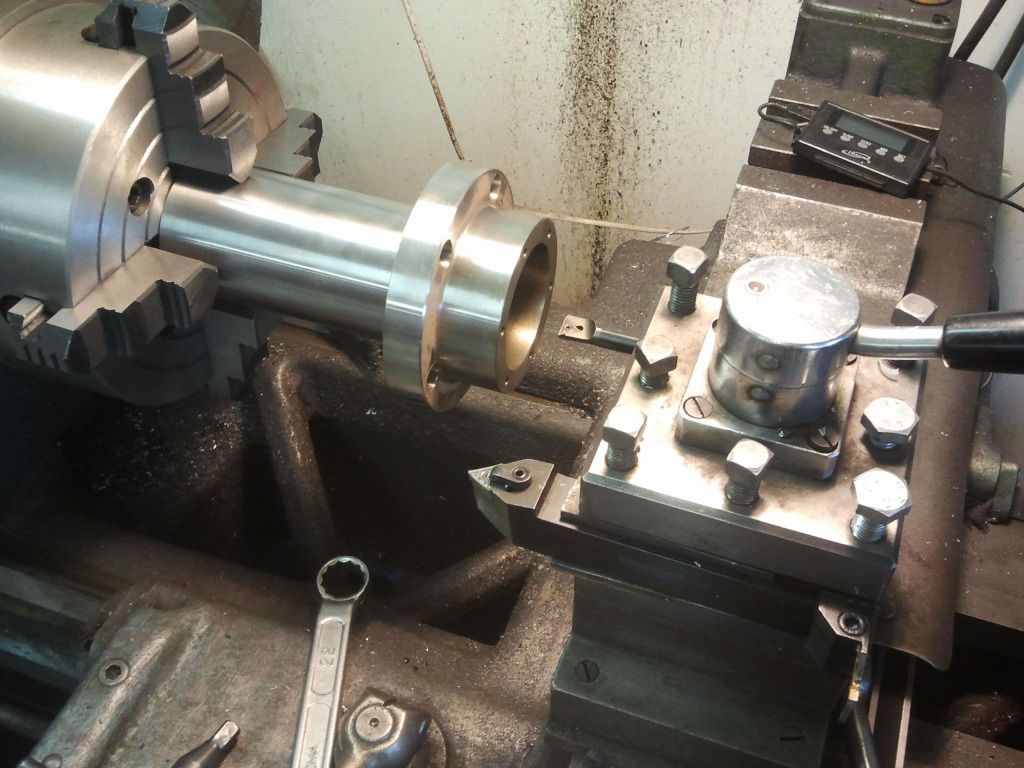

Next is the R8 spindle shaft.

-

08-07-2012, 06:49 PM #50

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

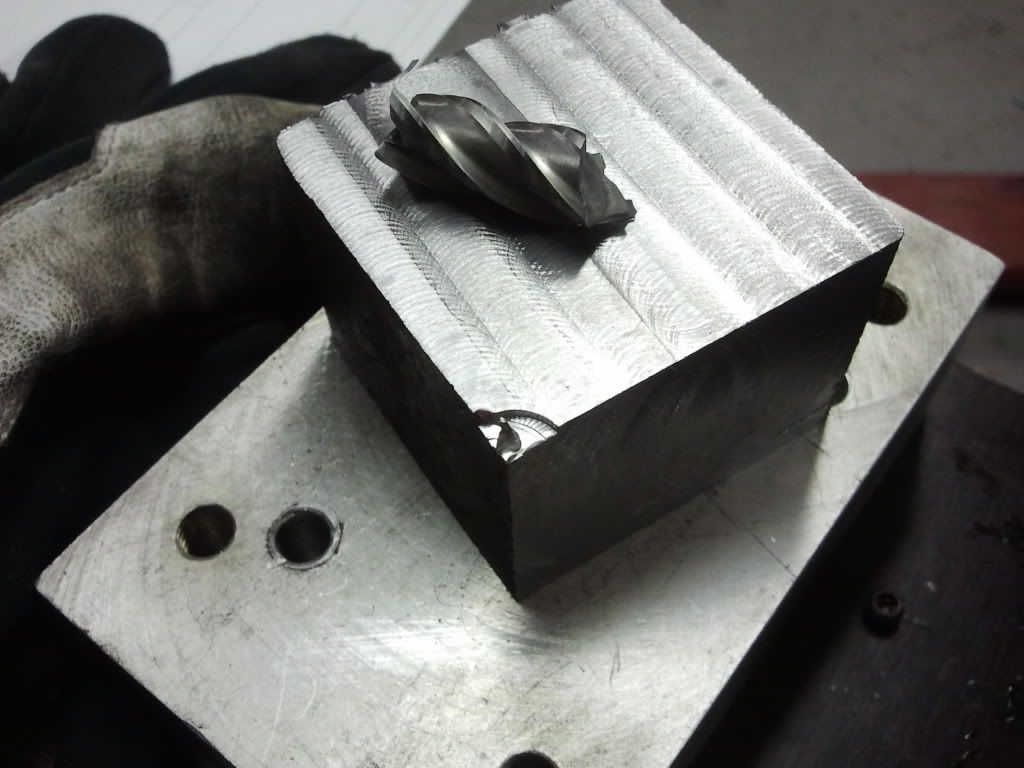

Damn, some measurements was wrong in solidworks..

-

08-07-2012, 06:50 PM #51

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

-

08-07-2012, 06:52 PM #52

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

Didn't have any round steel..

-

08-07-2012, 07:04 PM #53

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

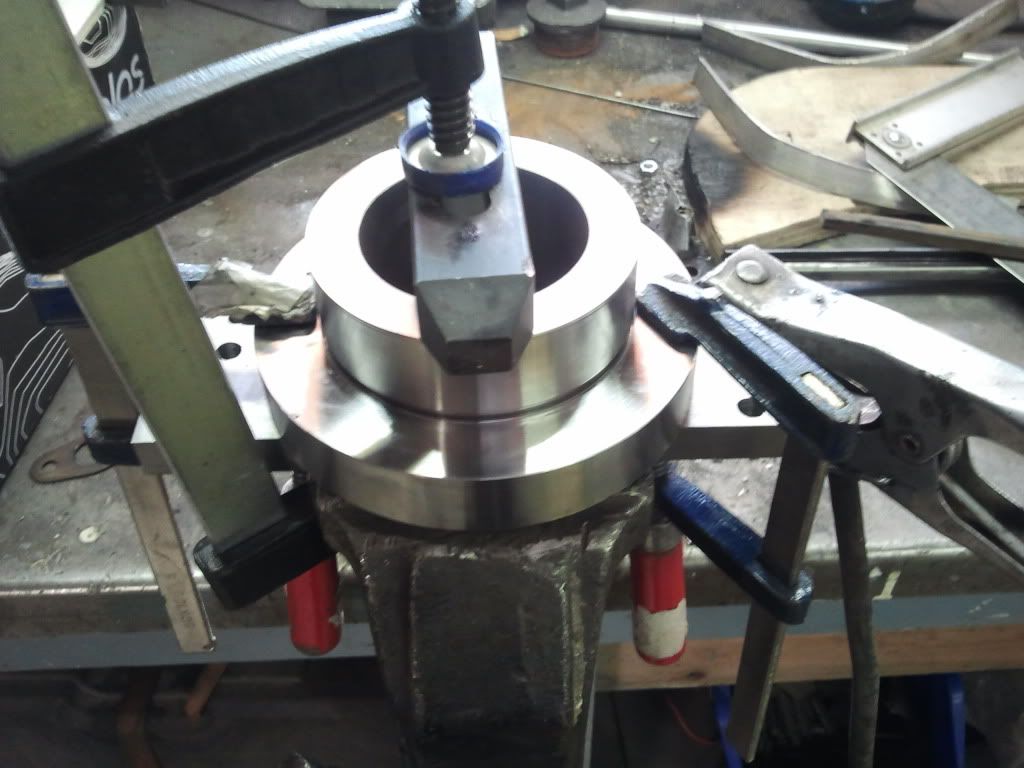

All Parts

Assembly

Tried to take better pictures.

-

08-07-2012, 08:02 PM #54

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

Now it's your turn to add some posts then I will continue at page 6

-

08-07-2012, 10:24 PM #55

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 161

I think you let us speechless... Awesome work, and that spindle looks impresive!

Is the connector on the body for air or oiling? I'm not familiar with this kind of taper, how is toololder retained? i see no springs or anything in your photos.

BTW, i'm working on a E/G machine too, for his one i've used a gantry design, but the next one, will be like yours, i really love the way you're geting things done!

Please, more updates

-

08-08-2012, 06:55 AM #56

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

It's for both cooling and oil, and I hope the air pressure willl keep chips away from the bearings.

About TTS:

About the Tormach Tooling System® | Tormach LLC | We provide personal small CNC machines, CNC tooling, and many more CNC items

It isn't much of an E/G machine after all (was going to put a smiley here but this forum doesn't have any useful ones..)

-

08-08-2012, 06:57 AM #57

Registered

Registered

- Join Date

- May 2007

- Posts

- 42

nice spindle

-

08-08-2012, 12:24 PM #58

Gold Member

Gold Member

- Join Date

- Dec 2004

- Posts

- 1865

Looking good!!!

MikeWarning: DIY CNC may cause extreme hair loss due to you pulling your hair out.

-

08-09-2012, 06:35 AM #59

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 291

I think "holy crap!" captures my response the best.

-

08-10-2012, 05:37 PM #60

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 38

Spindle seal

What kind of seals do you plan on using to protect the spindle bearings? What kind of spindle bearings did you use? Do you recall how much clearance you have around the spindle bearings in the housing?

Looking great!

Similar Threads

-

How to drill and face mill using table type horizontal boring mill

By SatishNaik in forum News AnnouncementsReplies: 0Last Post: 10-09-2013, 01:10 PM -

How boring, Face mill, End mill and Circular Interpolation done on Floor type HBM.

By SatishNaik in forum News AnnouncementsReplies: 0Last Post: 07-29-2013, 01:15 PM -

Home-Brewed CNC Bench Mill Using Siex X2 Mini-Mill Head

By fignoggle in forum Benchtop MachinesReplies: 18Last Post: 05-12-2009, 05:11 AM

Reply With Quote

Reply With Quote