hello

I started building a new 5-axis milling machine.

working area is 8x4x2 meter's

constructions with a quadrat tubes 100x100mm's

servo motors estun 0,75 kW with planetary gears, electronics folded markcomp77 colleague

end of the building somewhere in October

Meanwhile, some pics

elements in pictures are welded base

profiles were cut on the band saw &12 N Maktek (machine from China haha)

Thread: New machine build - big 5 axis

Results 1 to 20 of 177

-

07-09-2011, 08:43 PM #1

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

New machine build - big 5 axis

New machine build - big 5 axis

-

07-10-2011, 02:55 AM #2

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

Looks very good Bartuss1,

I'll be watching.

CarveOneCarveOne

http://www.carveonecncwoodcraft.com

-

07-10-2011, 04:09 AM #3

x2

-

07-11-2011, 05:12 PM #4

Registered

Registered

- Join Date

- May 2010

- Posts

- 307

Looks like you have a good start. Did you mean 8x4x2 feet working area? I have a 5-axis build with the same envelope planned (though not started, just collecting parts and finalizing the design at this point).

What is your intended work material? Given the design, I am guessing wood and foam.

Can you tell us more about your BC head? Are those planetary gears? What sort of backlash/torque/ratio rating do they have? What is your spindle power rating?

What is your Z column constructed of? The same steel tube? How do you plan to keep it from falling on motor shut-down? Have you considered the vibrations you will see when the Z column is fully extended?

I assume you are using rack and pinion on the long axes - what about Y and Z?

Do you have CAM software chosen?

-

07-11-2011, 06:21 PM #5

Gold Member

Gold Member

- Join Date

- Feb 2009

- Posts

- 2143

Looks like a nice follow-up to your last machine! Looking forward to the build process and updates...

CAD, CAM, Scanning, Modelling, Machining and more. http://www.mcpii.com/3dservices.html

-

07-11-2011, 06:44 PM #6

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

so, head BC will be of planetary gear apex dynamics 40:1, backlash <3' angle.

spindle will be elte 2,2 kW or combo 2 kW

construction Z column will be is a truss , cross-section 500x500mm.

I had already problems with vibrations in the previous machine.

Now I know how to eliminate the problem.

Processing machine for foam, and laminates.

I suggested to the customer Mastercam, or Zw3d cam.

-

07-11-2011, 09:44 PM #7

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 130

electronics folded markcomp77 colleague

I wonder... how long cable for sevodrive (encoder) will work properly?

8m axis (real 9m x 2... so.. about 20m of encoder cable)

-

07-16-2011, 04:48 PM #8

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

A bridge of the X axis

a long of 5,2 m's

-

07-16-2011, 08:59 PM #9

Registered

Registered

- Join Date

- May 2010

- Posts

- 307

wow!

-

07-18-2011, 02:59 PM #10

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 3447

looks awesome! How do you properly square everything up, and measure things? Pictures of the tools?

-

07-18-2011, 06:19 PM #11

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Holy crap! You'll need a crane to assemble this beast!

-

07-23-2011, 06:52 PM #12

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

Meanwhile, on a smaller 5-axis

[nomedia="http://www.youtube.com/watch?v=q1dpltnrI18"]rough milling goblet speaker - YouTube[/nomedia]

-

07-23-2011, 08:23 PM #13

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 663

Amazing .. simply amazing!

As was the CNC that was machining the goblet speaker in the youtube video.

-

07-23-2011, 08:54 PM #14

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

client came from the Ukraine ...

I milling 20 pcs, in the meantime waiting for parts to large machines

-

07-24-2011, 06:50 PM #15

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

YZ-axis cup of pneumatic counterweight

Z axis

head bearing suspension

-

07-24-2011, 08:30 PM #16

Junior Member

Junior Member

- Join Date

- Nov 2008

- Posts

- 412

Bartuss1: looking forward to see more pictures as you build it. In the end you will need a whole "gmina" to help you set in place

Forget about global warming...Visualize using your turn signal!

Forget about global warming...Visualize using your turn signal!

-

07-24-2011, 10:03 PM #17

Gold Member

Gold Member

- Join Date

- Jun 2011

- Posts

- 695

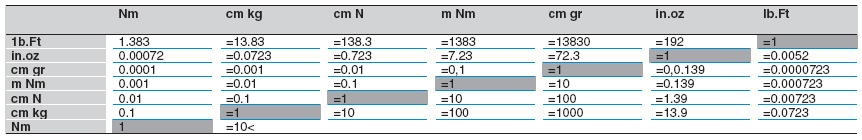

I have to assume the steppers will be listed in ft lbs and not oz. maybe horse power! :idea:

-

07-25-2011, 07:44 AM #18

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 130

-

07-25-2011, 10:06 AM #19

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

Left side of the base

-

07-25-2011, 11:24 PM #20

Registered

Registered

- Join Date

- May 2010

- Posts

- 307

Thanks for the pics - any of the welding process?

Similar Threads

-

My first CNC machine - Build

By clocksandblocks in forum DIY CNC Router Table MachinesReplies: 17Last Post: 07-26-2014, 08:42 PM -

4-axis machine build

By Kroko in forum DIY CNC Router Table MachinesReplies: 40Last Post: 09-14-2012, 02:34 PM -

3-axis machine build

By Kroko in forum DIY CNC Router Table MachinesReplies: 30Last Post: 04-23-2011, 10:55 PM -

CNC Machine Build

By CyborgCNC in forum Employment OpportunityReplies: 6Last Post: 08-04-2009, 09:28 PM -

New Machine Build

By skipper_52 in forum CNC Wood Router Project LogReplies: 8Last Post: 04-07-2008, 12:13 PM

Reply With Quote

Reply With Quote