I'm running a 3-axis homemade cnc machine with 3 xylotex 23H276-28-4B motors in it. My main type of material I am cutting is .75"-1.50" MDF Board. For example, most of my projects are 12"x19"x 0.75" thick. I import my design into Cut3D and that produces my Gcode. I have my feedrate set at 75 ipm and my plunge rate at 75 ipm spindle speed of 20,000 and am cutting with a 1/4" dia square bit in Cut3D, but when I run it on Mach 3 it almost takes an entire day just to cut out my design. Any solutions that can fix my issue? I believe its the feedrate that's my problem but should the spindle speed be set at a certain speed while in Mach 3? any and all help would be greatly appreciated!

Thanks to everyone in advance!

Marty

Thread: Correct Feedrates??

Results 1 to 12 of 12

-

06-01-2011, 06:42 PM #1

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Correct Feedrates??

-

06-01-2011, 11:12 PM #2

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

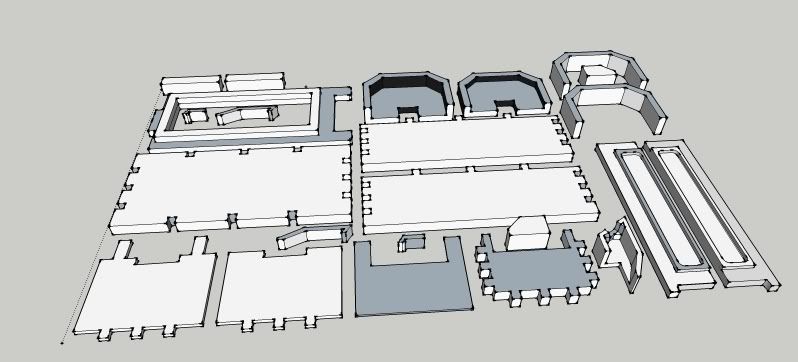

Can you post a pic of what you're making?

How fast can your machine go, and how much power does the spindle have? How deep are you cutting per pass?

You should be able to go up to at least 200ipm, and lower the rpm to 15,000 or less. Lower rpm's will keep your tools sharp longer.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-02-2011, 01:01 AM #3

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

My cutting depth is .375" using a 1/4" router bit but im actually gonna downsize to 1/8" to have a better finish. My stopover is .0625 but once again thinking about cutting that width in half for a better finish. As far as how fast it can go I don't know how to check for that im completely clueless. I think I remember reading that the max speed for the motors was 21,000 rims. My goal would be for the Cnc machine to cut this project in 2-3 hours less time would be great as well. Also the project pictured is. 75" thick.

-

06-02-2011, 01:09 AM #4

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Draw those parts in 2D, and use a 2D CAM program, and they'll cut in 1/10 the time. Cut 3D and Sketchup are the wrong tools for the job.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-02-2011, 01:12 AM #5

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Any suggestions on a 2D program that will work either fairly cheap or free?

-

06-02-2011, 01:24 AM #6

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Some of the parts show in the picture are they considered 2D or 3D. I would of considered them 3D.

-

06-02-2011, 03:09 AM #7

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

CamBam has a free version. Or Cut 2D.

Generally, those are considered 2.5D.

3D parts require all 3 axis moving at the same time. For your parts, the Z just needs to move to the correct depth, then all the cutting can be done with X and Y moves.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-02-2011, 03:16 AM #8

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Thanks you've been a great help, any suggestions on the federate, plunge rate and spindle speed for the 2d programs?

-

06-02-2011, 03:45 AM #9

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

I usually cut MDF at 150ipm and around 12,000 rpm. If you're machine is capable of it, you can cut much faster.

On our machine at work, we cut at about 1,000 ipm and 16,000 rpm, with a 15HP spindle.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-02-2011, 03:49 AM #10

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

The type of router im using is a rotozip rz20 and I believe it can run at 30,000 rpm. Is there a special type of equation that is used to determine the speeds?

-

06-02-2011, 03:53 AM #11

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Yes. Tool manufacturers will give you a recommended chip load range. You can use the chip load to determine rpm and feedrate.

Here's the chart for cutting MDF with tools from Onsrud.

MDF Cutting Data and Chipload Chart by Onsrud Cutter | | LMT Onsrud

Keep in mind that with a low power spindle like the RotoZIP, you may not be able to attain the recommended chip load.

For cutting MDF, a general rule of thumb is to cut as fast as possible, while maintaining acceptable cut quality. This will usually give you the longest tool life.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-02-2011, 03:57 AM #12

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Awesome, you've been a savior for me. Ill let you know how it goes tomorrow

Similar Threads

-

More Q's! Feedrates, etc

By binfordw in forum Benchtop MachinesReplies: 16Last Post: 03-29-2010, 01:21 AM -

feedrates for mdf board

By davidsutton in forum Material Machining SolutionsReplies: 2Last Post: 06-14-2009, 03:59 PM -

G0's and Feedrates???

By Moondog in forum Machines running Mach SoftwareReplies: 5Last Post: 04-18-2007, 09:26 AM -

Anyone got any X1 recommended feedrates...

By digits in forum Benchtop MachinesReplies: 6Last Post: 10-03-2006, 11:54 PM -

X1 Feedrates etc...

By itsme in forum Benchtop MachinesReplies: 2Last Post: 08-20-2006, 01:37 AM

Reply With Quote

Reply With Quote