The first EDM I ran was one of the first commercial EDMs out there. That thing had huge vacuum tubes like an old radio station. It appeared to work on the low voltage/high current principle. One feature that I noticed was the "automatic" feeder which used some sort of sensor on the current where if it made solid contact the tool would back up until proper arc was maintained. I'm told this was how early carbon-arc streetlamps worked.

I stumbled across this thread looking for a project and I'm pumped about this one. Stay tuned for further developments.

Personal info: In Jan 2009 I retired after 50+ years in the machinist/tool&die trade. I find I still have to build things.

Thread: Home Built Edm Machine

Results 101 to 120 of 142

-

07-14-2009, 10:38 PM #101

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 52

-

07-18-2009, 04:16 PM #102

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 1

-

08-21-2009, 12:03 PM #103

- Join Date

- Apr 2008

- Posts

- 3

Hi Ian,

I am new to this forum. I would like to build this edm too, could you also send me your design from the magazine? Here is my email address: [email protected]

Thank you in advance.

Btw, is this design the same as the one you have attached in the earlier post (with 7 jpg pages)?

greetings,

jlinggar

-

09-14-2009, 09:06 AM #104

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 6

May I also have the plans please

Hi Handlewanker

Can I also have one of your plan please?

my email address: [email protected]

-

09-14-2009, 12:12 PM #105

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 4

Ian,

Please forward me a copy of the plans as well.

Thanks, Mike

[email protected]

-

09-14-2009, 01:20 PM #106

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1268

Hey Handlewanker;

Would you share the plans with me? [email protected]

Thx.

Billbillyjack

Helicopter def. = Bunch of spare parts flying in close formation! USAF 1974 ;>)

-

09-15-2009, 01:11 AM #107

Registered

Registered

- Join Date

- Jun 2003

- Posts

- 232

Hi Handlewanker

Please send a copy of your plans to my email address: kenanton@ lycos.com.

Thanks

-

09-15-2009, 02:03 AM #108

Registered

Registered

- Join Date

- May 2007

- Posts

- 250

Hi Handlewanker,

I am interested this plan,Please send a copy of your plans to my email address: [email protected]

Thanks

Mongkol

-

10-14-2009, 01:32 AM #109

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 9

please one copy

Hi Handlewanker,

I am interested this plan,Please send a copy of your plans to my email address: [email protected]

thanks

Gabriel

-

11-04-2009, 02:11 AM #110

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 1

Hello Handlewanker,

This is my first post. Would you kindly share the plans with me? My email address is [email protected]

Thank you,

UT8

-

11-04-2009, 06:44 AM #111

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 1237

All you guys got the plans, has anyone completed it?

-

11-04-2009, 10:00 AM #112

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 15

Hello Handlewanker,Please send a copy of your plans to my email address:[email protected] tanks a lot

-

11-05-2009, 06:10 AM #113

Me too!

Me too!

Hi Handlewanker,

May as well add me to your mailing list.

I built Ben Fleming's Servo type sinker generator but am looking into other generators that can put out more useable amps for larger total electrode surface area.

-

11-05-2009, 11:29 PM #114

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 32

Me Too

May I also ask for your plans ? My email [email protected]

-

11-07-2009, 03:41 PM #115

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Skullworks, send me your email adress and I'll send them direct to you.

The plans are for a DIY model of quite modest ability so if you want something with a bit more grunt, maybe this is too "Model Maker" type.

Hi Santafesonido, I tried to send the plans to your email adress but got a message saying adress couldn't be found, I'll try again.

If that fails, the plans can be found on the earlier posts on this thread.

Ian.

-

11-07-2009, 11:52 PM #116

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 32

Thank you handlewanker for emailing your plans.

-

11-08-2009, 02:57 AM #117

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 4

Plans

Hi handlewanker,

Can I also have one of your plan?

My email address is: [email protected]

Thanks

-

11-16-2009, 08:43 PM #118

Registered

Registered

- Join Date

- Mar 2003

- Posts

- 104

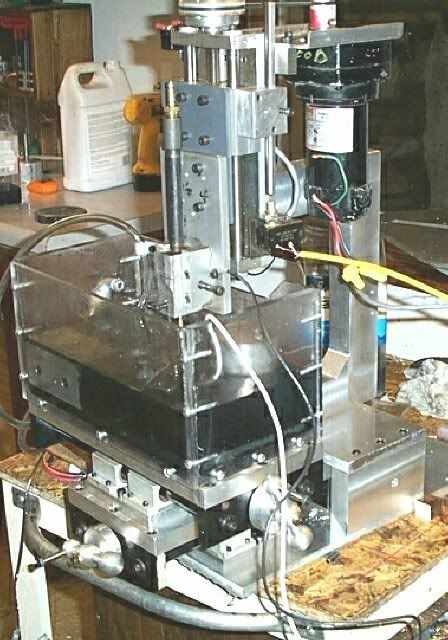

Here is my sinking EDM. For a downfeed I used a common 90 VDC gearmotor.

A PLC monitors the spark voltage and has the gearmotor go FORWARD/STOP/REVERSE for feeding the electrode.

To see it run click on the link:

http://smg.photobucket.com/albums/v3...EDMworking.flv

http://img.photobucket.com/albums/v3...Mtestspark.jpg

http://img.photobucket.com/albums/v3...rninginoil.jpg

Finished job:

http://img.photobucket.com/albums/v3.../EDMkeyway.jpg

Here is my wire EDM: It is not CNC (Yet). It is also controlled by a PLC.

Control cabinet and power supply cabinet:

Power supply plans came from:

"Build An EDM" by Robert langlois

Available from the Village Press, Inc

Calalog number 97-60656

ISBN Number 0-941653-52-8

The rest was built from my head. I have no drawings of the hardware.

Jimwww.outbackmachineshop.com

-

11-17-2009, 03:30 PM #119

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 32

I saw your pic of the coupling keyway cut with EDM machine. How would you compare if it is cut with a slotter or shaper ? What is the tolerance for fitnest cut with EDM ?

-

11-17-2009, 07:02 PM #120

Registered

Registered

- Join Date

- Mar 2003

- Posts

- 104

That slot or keyway was a blind hole. Not likely a slotter or keyway cutter could do it.

EDM always has an overburn of around .006 per side so you make the electrode undersize accordingly.

Jimwww.outbackmachineshop.com

Similar Threads

-

Needing help with my home built machine.

By whiteknight5951 in forum Stepper Motors / DrivesReplies: 13Last Post: 01-05-2014, 01:20 AM -

Frame design for home-built milling machine

By tom.k.cook in forum Drilling- and Milling MachinesReplies: 3Last Post: 04-09-2013, 08:30 PM -

Home built 5 axis machine

By csmoak25 in forum DIY CNC Router Table MachinesReplies: 6Last Post: 02-15-2011, 03:56 AM

Reply With Quote

Reply With Quote