Hi to you all, got a tricky little job coming up next week involving drilling and tapping a number of 2mm holes in gauge plate.

The holes will be 5mm deep blind holes, I will be tapping them on a Haas TM3 Mill using G84 and a 2mm machine tap.

I have never tapped such small holes on a mill so any advise on spindle speeds, coolants/cutting oils would be most welcome.

Many thanks

Results 1 to 11 of 11

-

09-03-2011, 11:00 AM #1

Registered

Registered

- Join Date

- May 2011

- Posts

- 53

Machine Tapping M2 in Gauge Plate

-

09-05-2011, 12:39 AM #2

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 443

What is "gauge plate"? It's not a term I'm familiar with on this side of the pond, so could you describe the size, shape and material type? It is similar to the 6061-T6 aluminum "tooling plate" we have here?

-

09-05-2011, 07:47 AM #3

Registered

Registered

- Join Date

- May 2011

- Posts

- 53

Gauge plate is a high carbon tool steel, usually pre machined then hardened. It is used for making gauges etc. Hope that helps

-

09-05-2011, 12:57 PM #4

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 443

So is this hardened before you tap it? If so, how hard? If not, do you have the tensile strength or other specification for the steel, such as EN24 or other European standard?

What class of thread do you have to make? How many holes? Does the machine have the rigid tapping option, or are you going to use a tension-compression tapping chuck?

Assuming this is like the A-2 (air-hardening) or O-1 (oil-hardening) tool steel stock that we have here in the US, you would get it in the soft stage and heat-treat after the machining is done. The reason why it's important to know the exact type of alloy steel is that there's going to be a small amount of shrinkage in the heat-treating process.

If I assume it's a low-shrinkage tool steel such as D-2, you would be fine using an ISO 3 class (6G/6GX) tap. Your safest way is to use a form tap, though which type you choose depends upon the total number of holes you have to do. Some high-performance PM (powered metal), coated taps can be VERY pricey, but actually give lower cost-per-hole as they last so long.

What tap you choose really depends upon the answers to rigid tapping capability, quantity of holes, material type and condition, shrinkage factor and rigidity of the process.

-

09-05-2011, 07:29 PM #5

Registered

Registered

- Join Date

- May 2011

- Posts

- 53

Lifted from a suppliers website.............

Tool Steel O1 is a medium alloyed oil hardening steel with excellent cutting force and toughness, the excellent dimensional stability reduces distortion and the possibility of cracking during heat treatment.

Supplied in the annealed condition, the precision tolerances minimise additional costly tool room machining.

Ground Flat Stock provides toolmakers with a decarburization free surface, plus a high wear resistance after heat treatment, making it ideal for a multitude of uses and applications: dies, press tools, punches, gauges, cams, jigs, machine knives and marking devices.

Hardness as supplied: 229 Brinell max

Tensile Strength: 45 Tons / sq. in.

Table of Equivalent specifications:

AISI Werk. No. AFNOR British Spec.

O1 1.2510 95 MCWV5 BS4659 BO1

I have 8 holes to tap in 6 plates so that's just 48 holes to do. I will be using the rigid tapping cycle on the mill. I am not chasing time on this job, just need to make sure i don't break the taps so quite happy to run a slower spindle speed if that's what's required.

Thanks

-

09-05-2011, 09:39 PM #6

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 443

Thanks for providing the details.

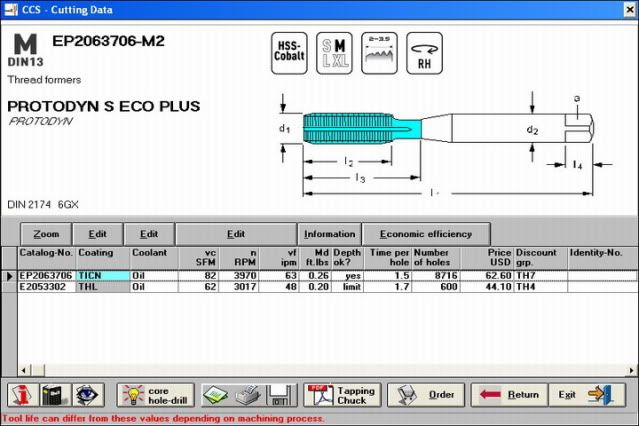

I have the Titex-Prototyp "TEC+CCS 10.2" software installed on my PC, so I ran it for you using all your data. I went with the tighter-tolerance 6G taps to help assure in-tolerance holes after heat-treatment.

First up is the premium roll form tap, a Protodyn S ECO Plus. Note the number of holes predicted per tap. It's a PM (powdered metal) TiCN-coated tap.

Next is the premium spiral flute tap, Paradur ECO-HT with THL (hard-lube) coating. It's also a HSS-Co PM tap.

For the lower number of holes and the fact that you'll be heat-treating the parts after machining, I lean toward the spiral flute tap as it's more-likely going to cut to size. A form tapped hole might have a little more shrinkage at heat treat.

It's list prices in US dollars that are showing. You'd have to contract a distributor in the UK for your pricing.

-

09-07-2011, 07:45 AM #7

Registered

Registered

- Join Date

- May 2011

- Posts

- 53

Thanks for the help and advise, managed to get through this job without any major trauma.

-

09-07-2011, 11:02 AM #8

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 443

So did you use a spiral-flute tap or something completely different?

-

09-07-2011, 12:22 PM #9

Registered

Registered

- Join Date

- May 2011

- Posts

- 53

I ended using a spiral point tap but I bottled out on going to full depth with it. Just finished the holes off with a bog standard hand plug tap and being very careful.

Thanks

-

09-09-2011, 11:58 AM #10

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 443

Well I'm glad for you that it worked out OK and you made good parts.

In the future I won't spend that much time trying to help someone get high-probability of success if you're willing to take chances with "it might work" kind of tools.

-

09-09-2011, 05:39 PM #11

Registered

Registered

- Join Date

- May 2011

- Posts

- 53

Hi Pix Man, I really appreciate the fact you went to quite some length to help me but I am a lowly setter/programmer/operator and unfortunately I do not control the purse strings (fortunately some might say) Our department is more of a prototype/specials than a production environment so we can't always buy everything we want.

For what its worth, I totally agree with you, I always think its best to have the right tooling for the conditions, maybe I should have been a little clearer about the info i was after in my OP. but thanks anyway.

Similar Threads

-

Another machine rigid tapping (stepper machine)

By samco in forum LinuxCNC (formerly EMC2)Replies: 11Last Post: 02-12-2019, 05:53 PM -

Can anyone machine a tooling plate for me?

By Nateg281 in forum Benchtop MachinesReplies: 15Last Post: 06-29-2010, 02:35 AM -

Machine Large Alu Plate for CNC router

By wfung in forum MetalWork DiscussionReplies: 6Last Post: 12-11-2007, 11:07 PM -

Tapping Fine Threads in Copper Plate

By tobyaxis in forum MetalWork DiscussionReplies: 9Last Post: 05-22-2006, 07:27 AM -

tapping head vs hand/cordless tapping machine....

By InspirationTool in forum Uncategorised MetalWorking MachinesReplies: 6Last Post: 09-13-2005, 02:10 AM

Reply With Quote

Reply With Quote