Here are a few pics of the putters we produced. These are old prototypes and in rough shape but they show the basics of what we made. They are missing the eliptical rear weights.

Judleroy

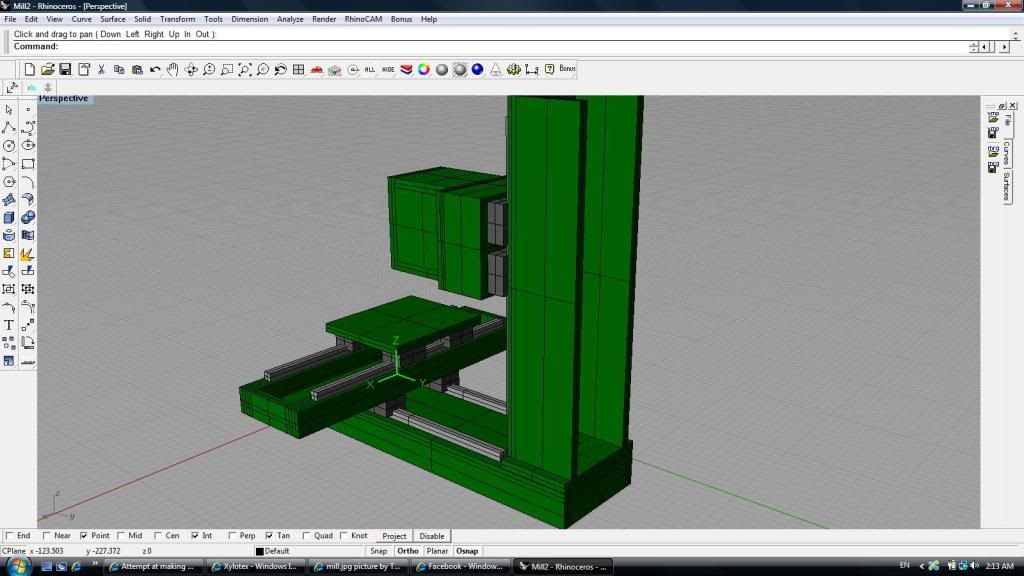

Thread: DIY aluminum vertical mill build

Results 61 to 80 of 82

-

02-04-2010, 06:44 AM #61

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 406

-

02-04-2010, 07:03 AM #62

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 201

hmmm, never seen those before. Approx how many did you guys make?

On another note, I found the power limit of the spindle motor tonight. No damage done to the machine and there was still a lot left of the part to mill off so it was OK. Spindle bogged, internal breaker went and the mill kept going, twisting the part in the vise and scraping the insert along the top.

It was running 1" width of cut (Sherline 1.125" single insert facing tool), .05" depth at 30 IPM in 360 brass. Too much. Cut the feed down to 15 IPM and it runs fine. Just calculated it, was 1.5in^3/min, now .75in^3/min. Still very respectable.

Serge

-

02-04-2010, 07:35 AM #63

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 406

The one on the right in the first pic is a prototype but very close to the finished product.

We made as a guess around 2000 of them. The second one is a prototype we made about ten of. I work machining putters for about 6 years. The company is gone now. We made and tested about 50 different models. Many of those I really liked alot.

judleroy

-

02-04-2010, 07:51 PM #64

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 201

Stage 3 vid is up. This is at 1" width of cut, .05" depth of cut, 15 IPM.

-

02-05-2010, 07:40 PM #65

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 375

Very, Very, Very Nice........

Hope you will make a lot off money with the machine,

Did you got all the linear products from ebay? Prices???

Very cool

-

02-05-2010, 08:25 PM #66

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 201

Thanks veteq!

Yep, all linear components were bought off ebay. I think the ballscrews averaged about $120 each and the rails $100 a pair. So about $660 plus shipping, duty, etc... I guess about $750. All rails are THK, ballscrews are NSK and Kuroda ground, great stuff. Certainly worth the money paid.

-

02-05-2010, 08:27 PM #67

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 201

Oh, here is the finished putter.

-

03-01-2010, 01:53 AM #68

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 201

Another milling vid...

[ame="http://www.youtube.com/watch?v=GCanSozscUg"]YouTube- radius stage1.mp4[/ame]

-

03-01-2010, 01:54 AM #69

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 201

Sorry, double post.

-

03-01-2010, 03:11 AM #70

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Wow, Serge.

I don't know how I missed this. Great job on it. Spindle worked out great as well from the looks of it.

I may have gotten lucky with my X2 heads. I wound up with two good ones. I did have some minor issues with just a plain spindle without a head for the lathe. I had to turn it down some to fit a chuck.

I also had much better luck after I replaced the bearings with better ones and made sure they were installed properly.

I can tell what they lack in the Factory over there is QC.

None the less though, the Sherline spindle works well.

The whole thing works well.

One comment made earlier in the thread about the width of the base. I too had 6" base and my linear blocks may have hung over each side about 3/8" at most.

Once I changed to the short table design, there were no issues at all with this width.

The short tables mass is always over the bearings without a lot over hanging anywhere. The other style with a long moving table would benefit greatly with a wider base.

Anyway.

Look forward to seeing the enclosure. I have seen some done with a shower curtain too. For the time being, that may be a solution.

I did notice some plywood in the videos. Is that the enclosure already?Lee

-

03-01-2010, 06:05 AM #71

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 201

Thanks Lee.

Thankfully, the Sherline spindle has worked out really well. The bigger case of the "industrial" version coupled with rock solid mounting (in a .05" deep close fitting slot, held by 6 1/4-20's) helped a lot. Good thing, as I really like the Sherline tooling.

The mill itself is rock solid. Putting my hand on the spindle case during the cut it feels exactly like it does when on not in the cut. Finishes have been excellent and it is extremely repeatable. As you said, the long saddle short table is the way to go.

The enclosure is done. 1/4" plywood at the back and sides. The back is screwed on to the bench and the sides are hinged and held in place with sliding locks on blocks attached to the back and the bungee cord to keep it firm. A C shaped extrusion was glued on to the insides of the side walls at the front and a 3' by 2' acrylic sheet is slid into this. Very simple, not pretty but it keep most of the chips inside and allows me to get at the machine when needed.

The shower curtain material you see is the way covers. It's held in place with with aluminum strips around the table as one piece (covering X and Y) and another piece coming off the bottom of the column. So far it's worked great.

Serge

-

03-01-2010, 08:45 AM #72

Member

Member

- Join Date

- Sep 2005

- Posts

- 1195

Sergizmo,

That putters are made off steel? So that small mill can cut steel, good.

-

03-01-2010, 08:46 AM #73

Member

Member

- Join Date

- Sep 2005

- Posts

- 1195

milling steel

milling steel

Sergizmo,

That putters are made of steel? So that small mill can cut steel, good.

-

03-01-2010, 06:13 PM #74

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 201

All putters so far have been free machining brass. I think it could cut steel, but the depth of cut and feed rate would have to be a lot less.

-

03-01-2010, 06:36 PM #75

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 264

beautiful machine. I noticed on your website you have an engine-turned finish and antiqued, how do you make those finishes (if you don't mind sharing)?

FS: Complete Z-Axis Assembly with THK RSR15WM slide, leadscrew, stepper mount. PM for more info.

-

06-10-2010, 02:16 PM #76

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 0

Hey man, I need to ask you some questions, PM'd you.

-

11-15-2010, 08:25 PM #77

Registered

Registered

- Join Date

- May 2008

- Posts

- 23

Without seeing this thread, I was thinking about making something very similiar... scary similiar..

Glad someone took the time to work out the details and processes, so I don't waste time and money.

BIG thanks!

-

05-29-2012, 02:05 PM #78

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 0

Hi , impressive work. A novice question, will the accuracy and rigidity be improved greatly if one decided to use cast iron or somewhat similar stronger materials (than aluminium) for the mill structure ?

-

12-30-2012, 06:18 PM #79

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

the design of this machine indeed looks quite similar to mine..

being copied is some sort of being told i was right in the first place..

i only put in more effort to make the machine very compact.. that's why my Y-axis motor sits in the base of the collumn..

this machine looks the business.. a toolchanger of some sort is also high on my wishlist..

-

05-26-2013, 05:14 PM #80

Registered

Registered

- Join Date

- May 2010

- Posts

- 88

Hi Sergizmo,

Love the build and thank you for sharing your construction details and thought process. Would it be possible for you to take a few pictures of how you installed the rails and the carriage/saddle assembly? I see you have a nice vise mounted but I would like to get a look at how the complete assembly.

Take care,

Shane

Similar Threads

-

cnc vertical mill build log ( pics )

By katran in forum Vertical Mill, Lathe Project LogReplies: 122Last Post: 02-18-2024, 03:54 PM -

400W Mitsubishi HC-PQ43 Servos - choice for Vertical mill build

By fcp in forum Servo Motors / DrivesReplies: 0Last Post: 01-05-2013, 11:51 PM -

Looking to build a simple vertical mill

By Crudeau in forum Benchtop MachinesReplies: 7Last Post: 10-27-2012, 01:13 PM -

Custom CNC vertical Mill build T-Minus 24:00

By cncgabe in forum Vertical Mill, Lathe Project LogReplies: 37Last Post: 03-31-2012, 02:18 AM -

1st CNC Build - Aluminum & PCB Mill

By viroy in forum Open Source CNC Machine DesignsReplies: 2Last Post: 02-24-2009, 04:39 PM

Reply With Quote

Reply With Quote