some updates,

Better column mount with secondary brace greatly reduces spindle deflection.

I finished building the spindle indexing system and tested it out.

It works fantastic. As for now I have a strong 425oz motor on it so i can run pretty tight backlash.

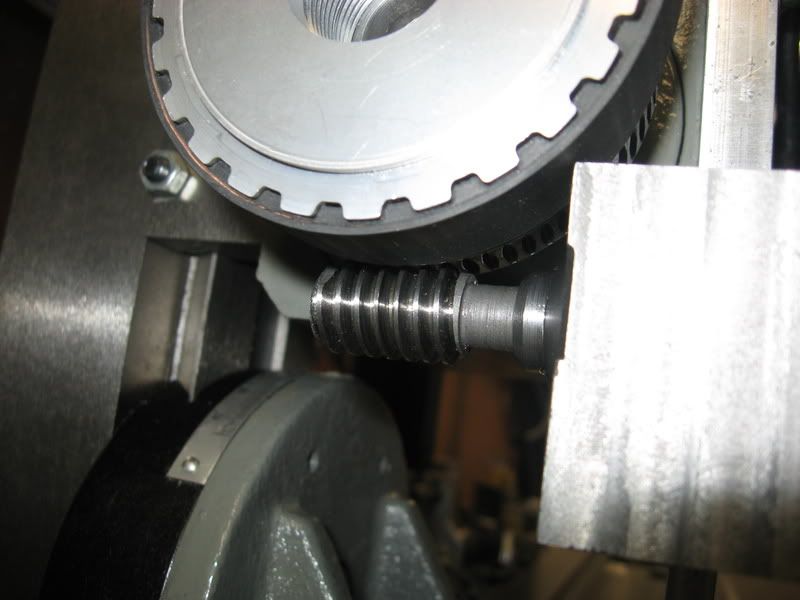

An external gear was added to the drive system. An Iron block with a precision bore is mounted to the headstock. Inside the bore is fitted an eccentric shaft keyed which itself is bored to accept the worm gear which provides the bearing surface.

To engage the drive you grab the stepper and rotate it 180 degrees and because of the eccentric, the worm meshes with the ring gear. It locks into place with a ball spring detent inside the iron block. To disengage the drive, just turn the stepper 180' opposite. No tools needed, no belts to remove nothing. Works perfectly.

This was the last major hurdle. I'm now ready to begin final assembly, alignment and then bore the end column support bushings.

Steve

Results 1 to 20 of 52

Hybrid View

-

02-02-2009, 09:19 PM #1

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Similar Threads

-

horizontal cnc boring machine?

By bp092 in forum Commercial CNC Wood RoutersReplies: 1Last Post: 10-25-2007, 03:51 AM -

Machinist - Horizontal / Vertical boring mill operators

By quinnj in forum Employment OpportunityReplies: 0Last Post: 10-18-2007, 05:26 PM -

Horizontal and Vertical boring mill operators

By quinnj in forum Employment OpportunityReplies: 0Last Post: 10-16-2007, 07:58 PM -

Horizontal Boring

By harryn in forum K2CNCReplies: 9Last Post: 06-30-2007, 05:37 AM -

New Photos! Horizontal Boring Mill (30HP)

By mzartop6 in forum CamSoft ProductsReplies: 1Last Post: 09-12-2006, 02:11 AM

Reply With Quote

Reply With Quote