Thanks Topdecking! I agree that it would probably look cool with a full enclosure. I have kicked the idea around of building a fixed enclosure. It would have an access door on the tailstock end. As it is though, without the full enclosure, I have good access for tool changes, cleaning, tail stock, etc. For now I think I may try running it as it is and see how I feel about it. I suppose one option is to build a fixed rear enclosure that sits directly on the table with a rear access door. The front sliding door would slide underneath the fixed enclosure. The fixed enclosure could sit inside the coolant pan so it didn't move around but still could be lifted out of the way and set aside for cleaning, maintenance, setup.

My next step is to build a little sheet metal pan that sets on top of the lower front rail/all thread and guides the coolant to the middle of the lathe. Then I will figure out the chip/coolant pan that sits underneath the lathe to collect the coolant. I have two chip pans to work with at the moment. One is the original G0602 pan, another is a 12x36 pan I have from some project. The 12x36 pan is too long and would need to be shortened up, but the sides are much deeper.

Results 81 to 100 of 235

-

04-03-2013, 04:57 PM #81

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

-

04-03-2013, 05:35 PM #82

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 205

The automotive parts places have a 24x36 drip pan that might work.

Don

-

04-03-2013, 06:44 PM #83

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

-

04-04-2013, 12:34 AM #84

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

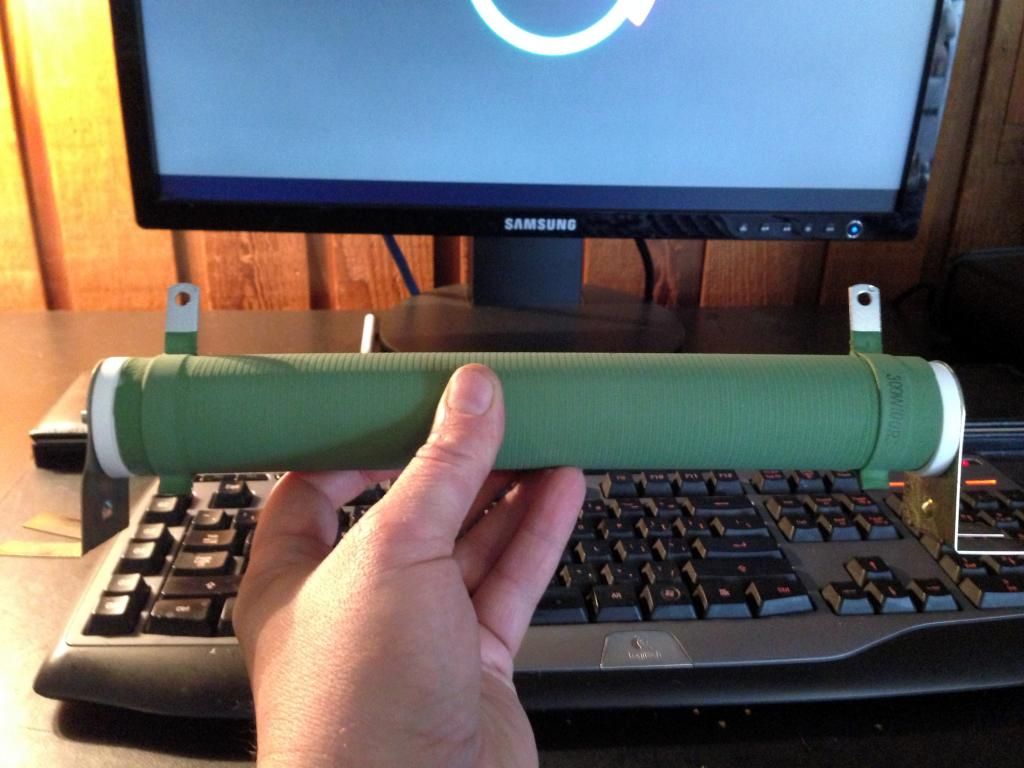

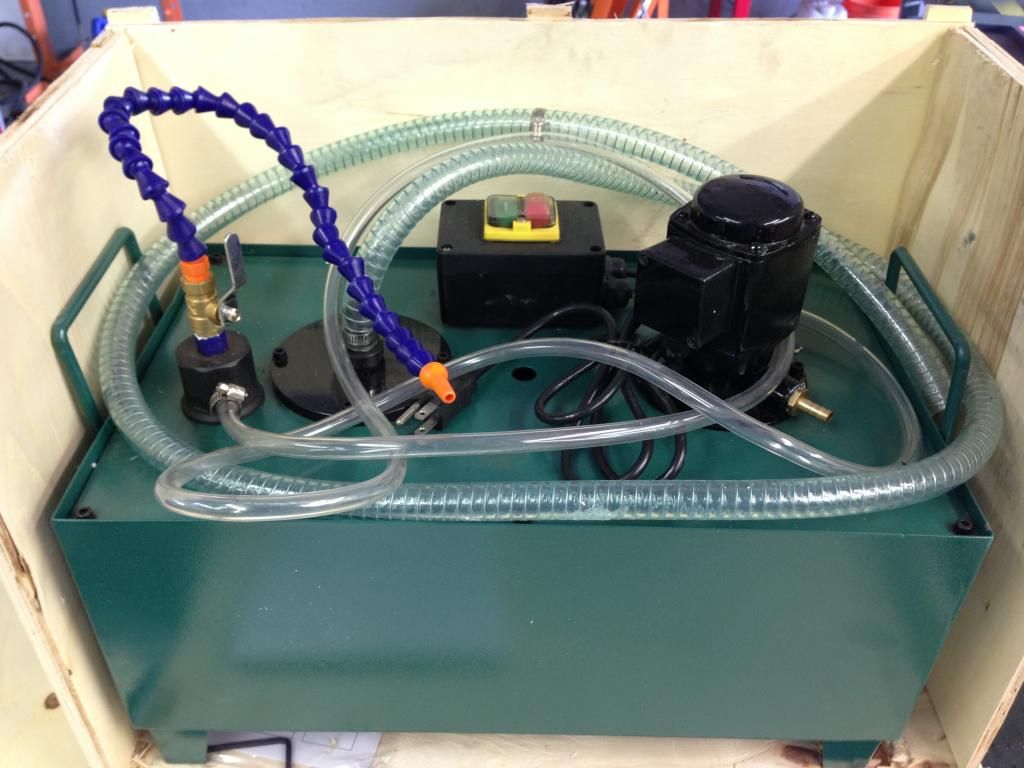

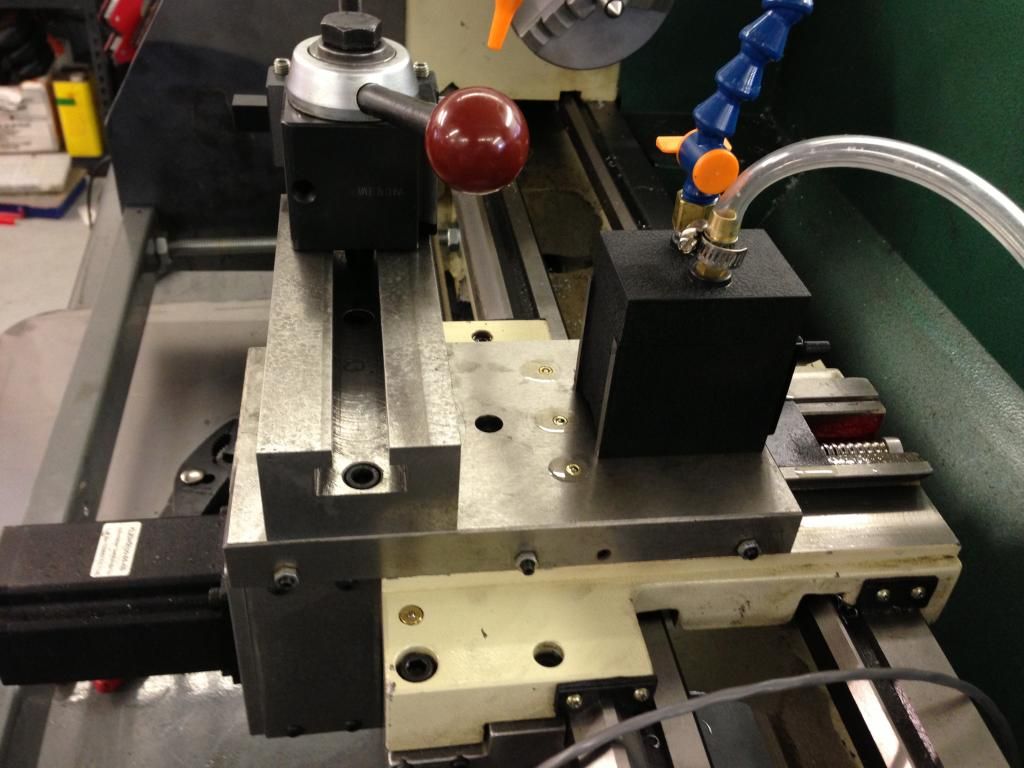

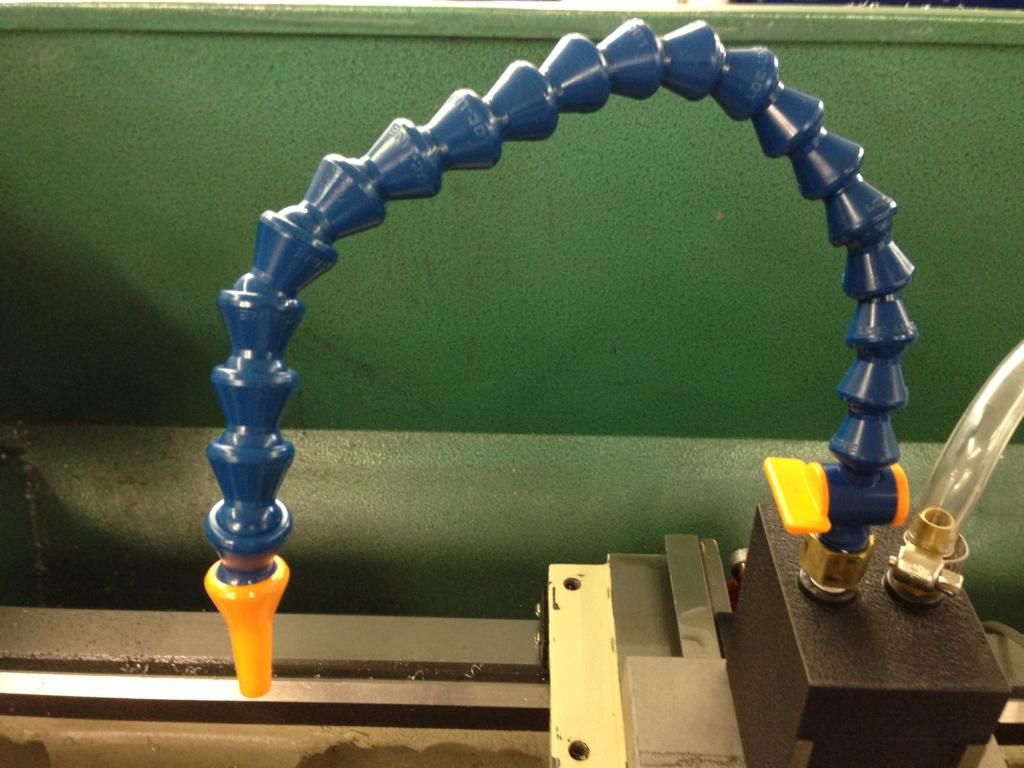

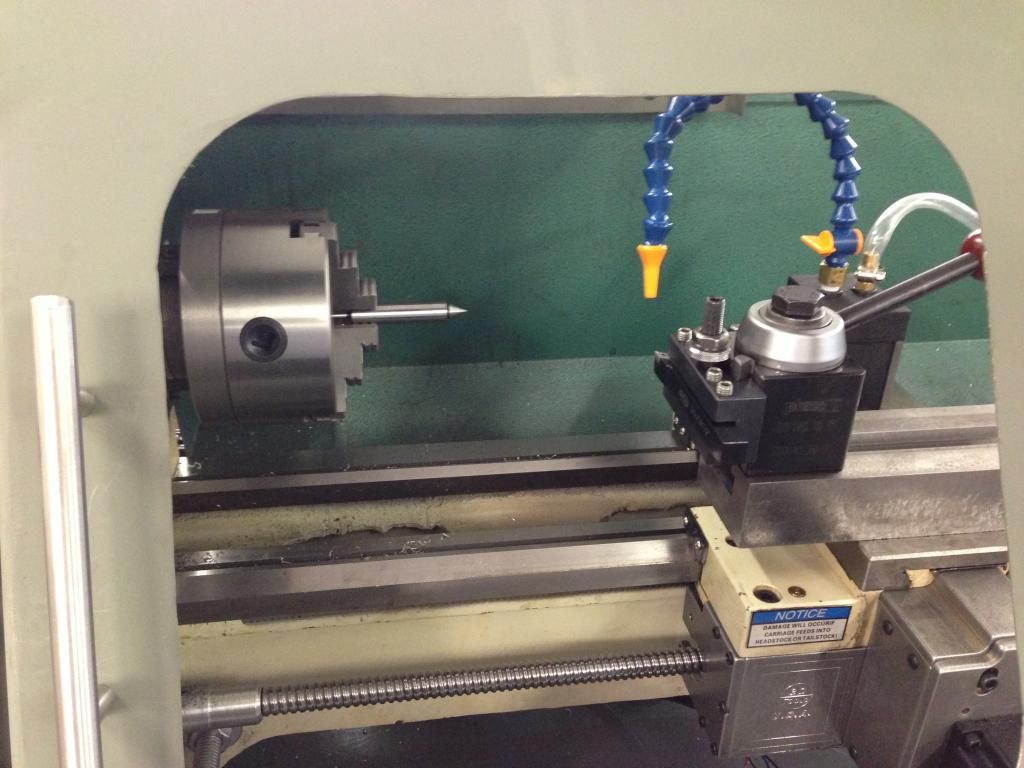

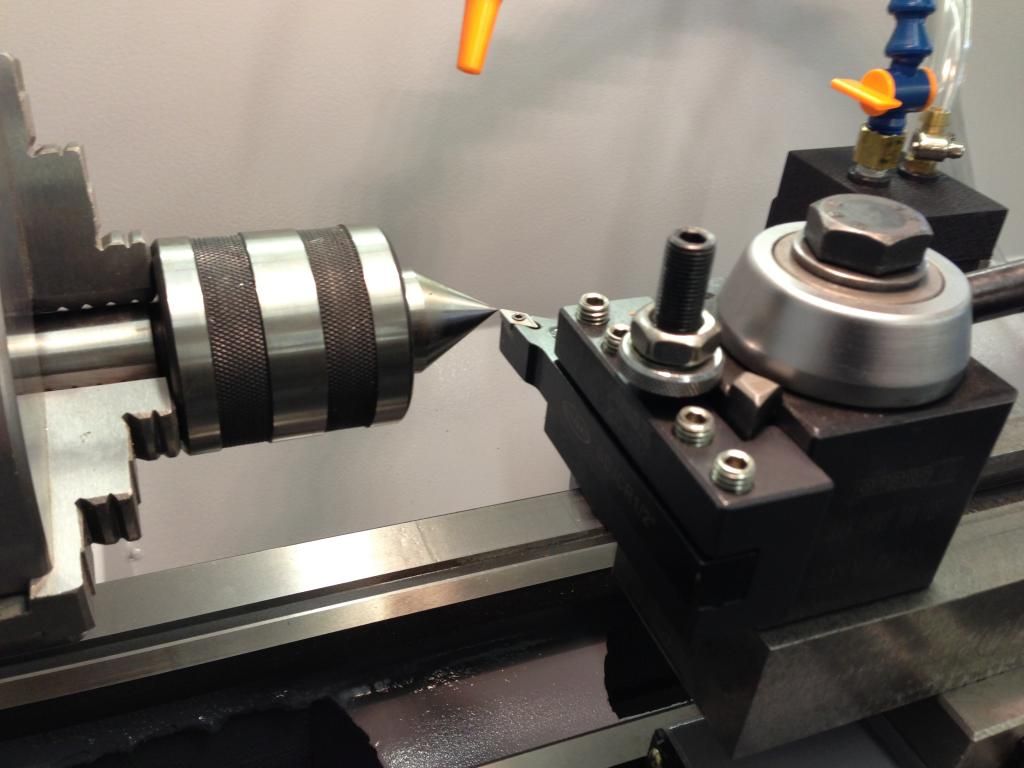

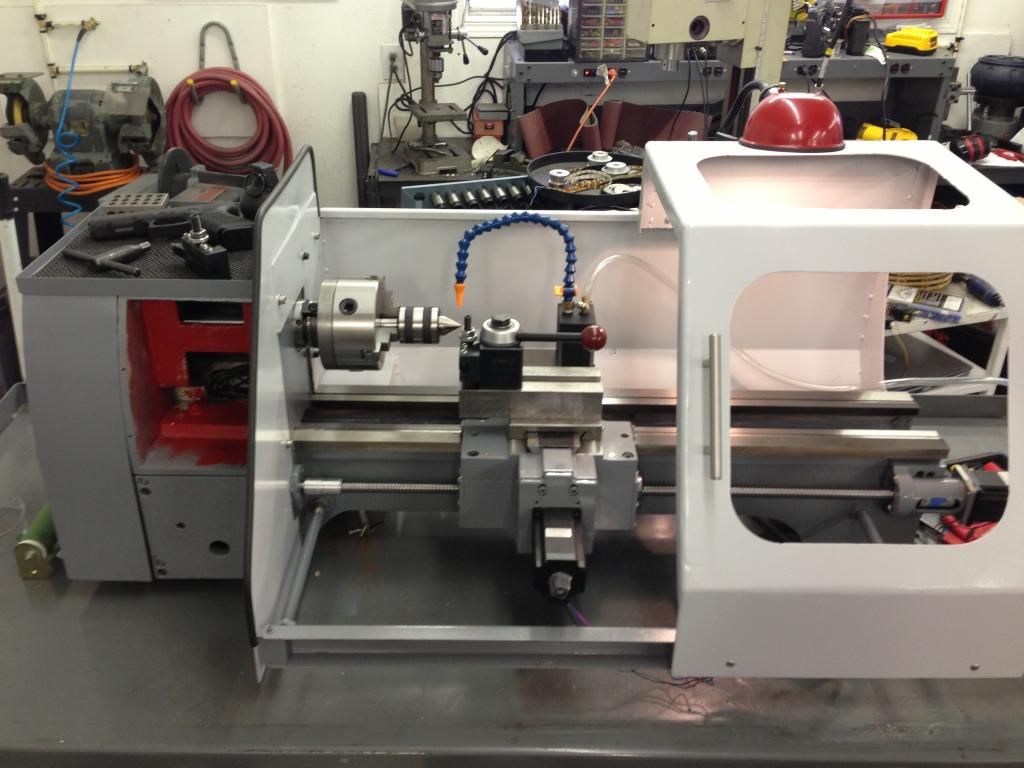

The coolant setup arrived from Grizzly today. I swapped out the Chinese loc-line copy for USA loc-line. Just my personal preference and it happened to be laying around. The pump unit looks good. Saves a lot of hassle plus its pretty mobile if needed. I like the handles.

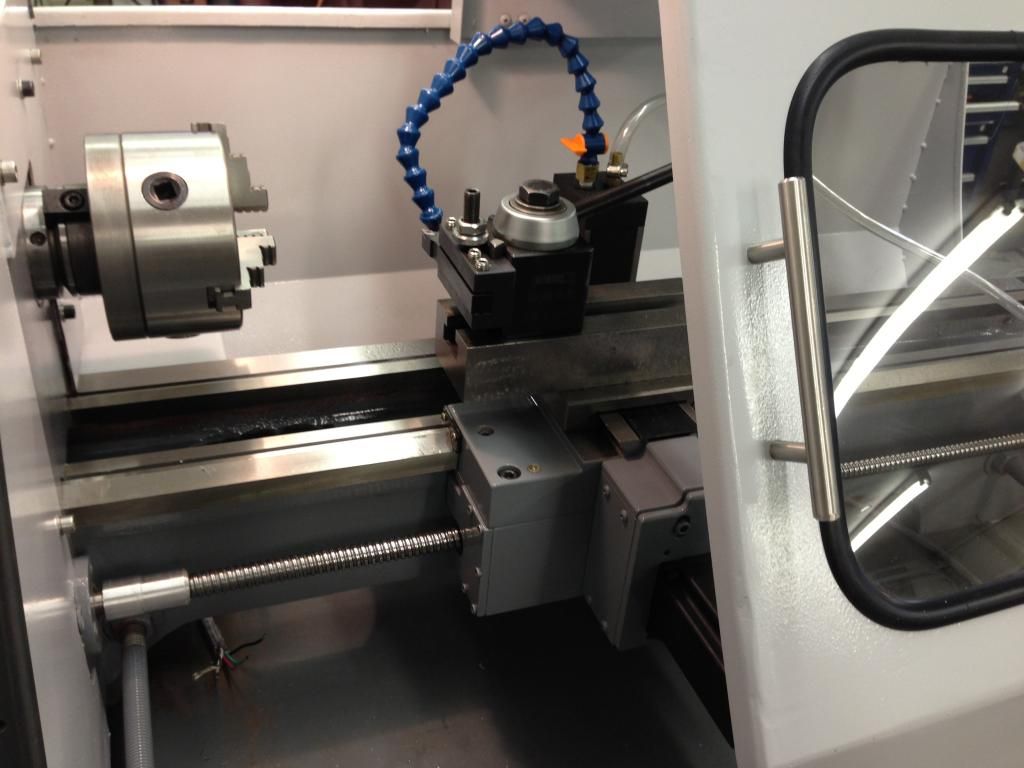

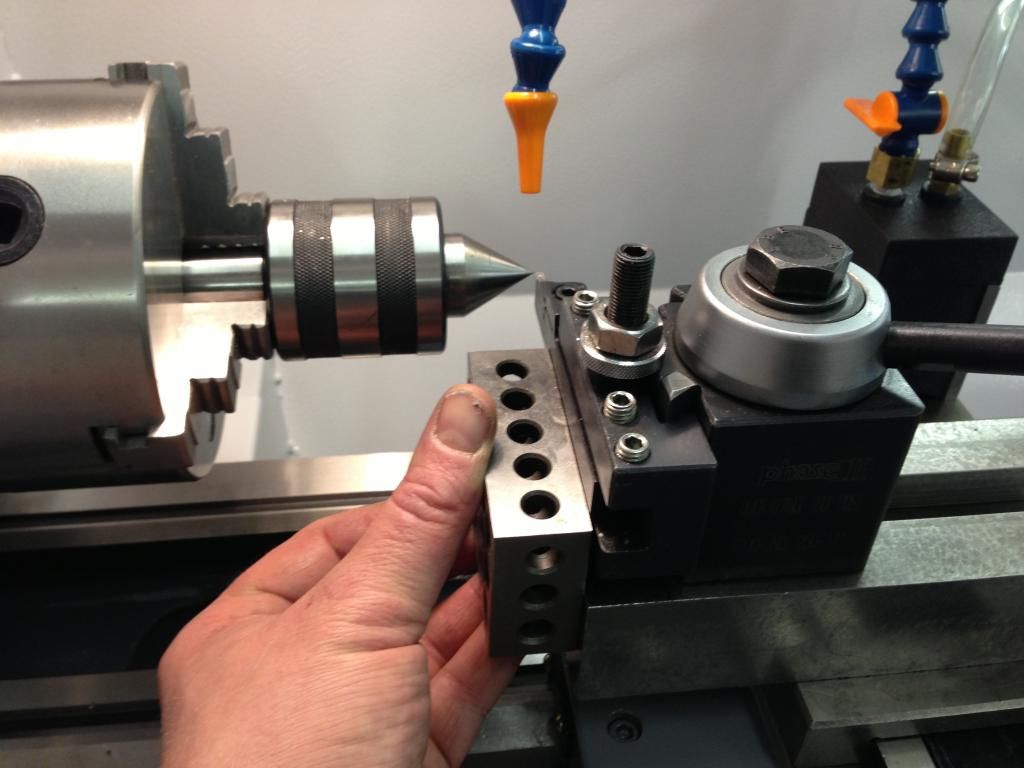

Today I got my tool post spacer mounted. I need to machine the T-nut next. I can flip the tool post spacer 180 deg if I need a little extra rigidity. I countersunk two hardened M8 cap screws in the spacer and threaded them into the original compound mounting holes. I also squared up the saw cut ends of the tool post spacer on the bridgeport.

-

04-05-2013, 03:22 AM #85

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

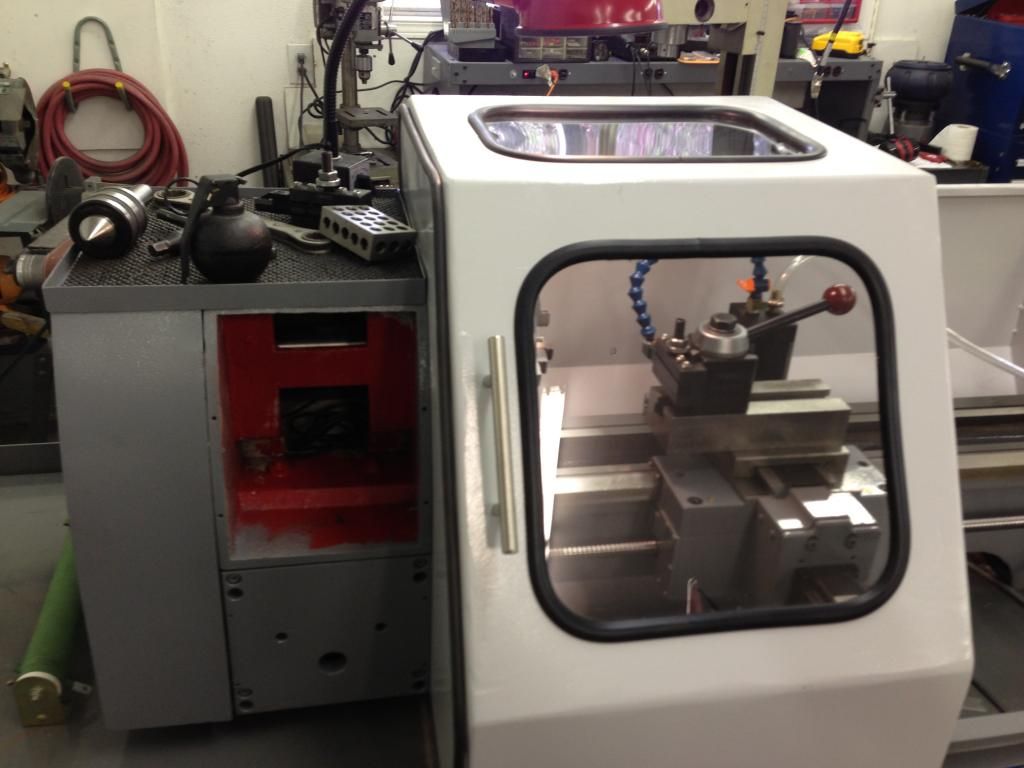

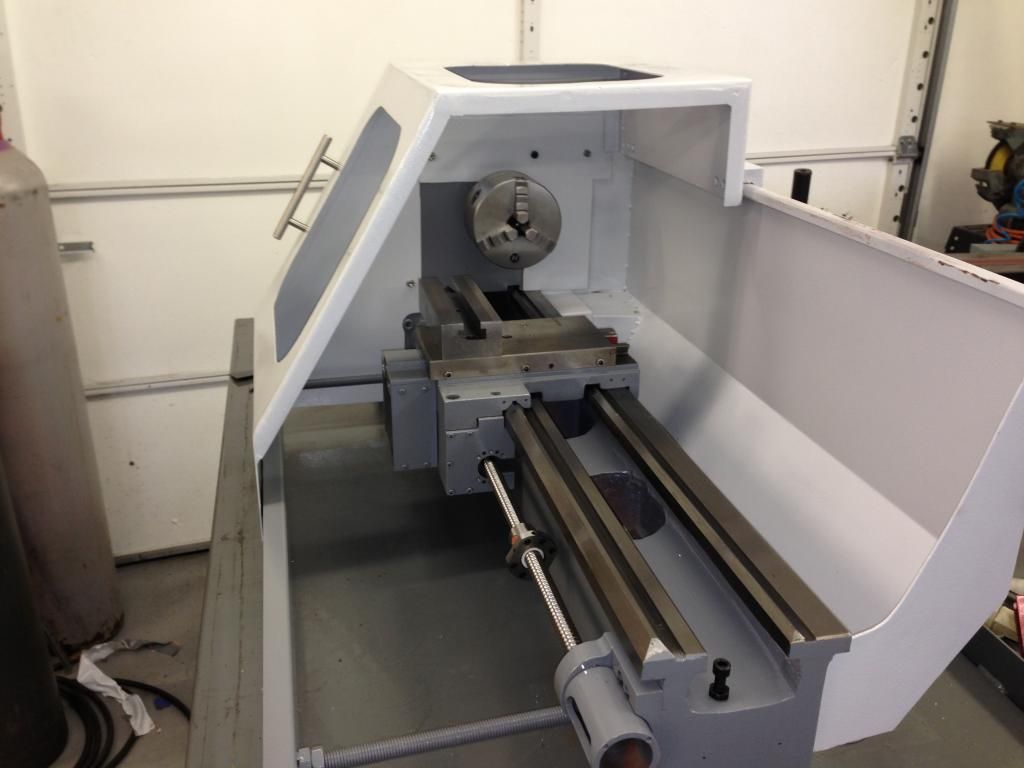

Here is today's enclosure update. Mostly detail stuff that I have been dragging my feet on.

G0602 CNC Enclosure update - YouTube

-

04-05-2013, 03:42 AM #86

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 124

That really is a beautiful machine. The 5/8 rod out segment is a great idea I think you'll see others (and myself) use.

-

04-05-2013, 04:27 AM #87

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

The threaded rod is nice for this application because it allows me to tweak the adjustment of the lower rail in and out. I originally drilled and tapped 5/8 threads into the side of the lathe. Today I decided I wanted to weld the nuts to the back of the lower rail so the all thread was not protruding through the rail like the original design. This forced me to drill out the original holes I tapped into the lathe and use a nut on both sides to lock the all thread to the lathe. Now the rail looks cleaner and the door slides open further.

-

04-05-2013, 04:30 AM #88

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

And here is one cool feature I forgot to mention.

Enclosure removal demonstration - YouTube

-

04-05-2013, 02:19 PM #89

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 41

Looking great, Matt!!!

Dave

-

04-07-2013, 02:15 AM #90

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

-

04-07-2013, 02:55 AM #91

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 41

Uhhh. yaaauh, that is a LOT bigger than I thought. (why do I sound like a girl saying that? lol!)

Dave

-

04-07-2013, 06:02 PM #92

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

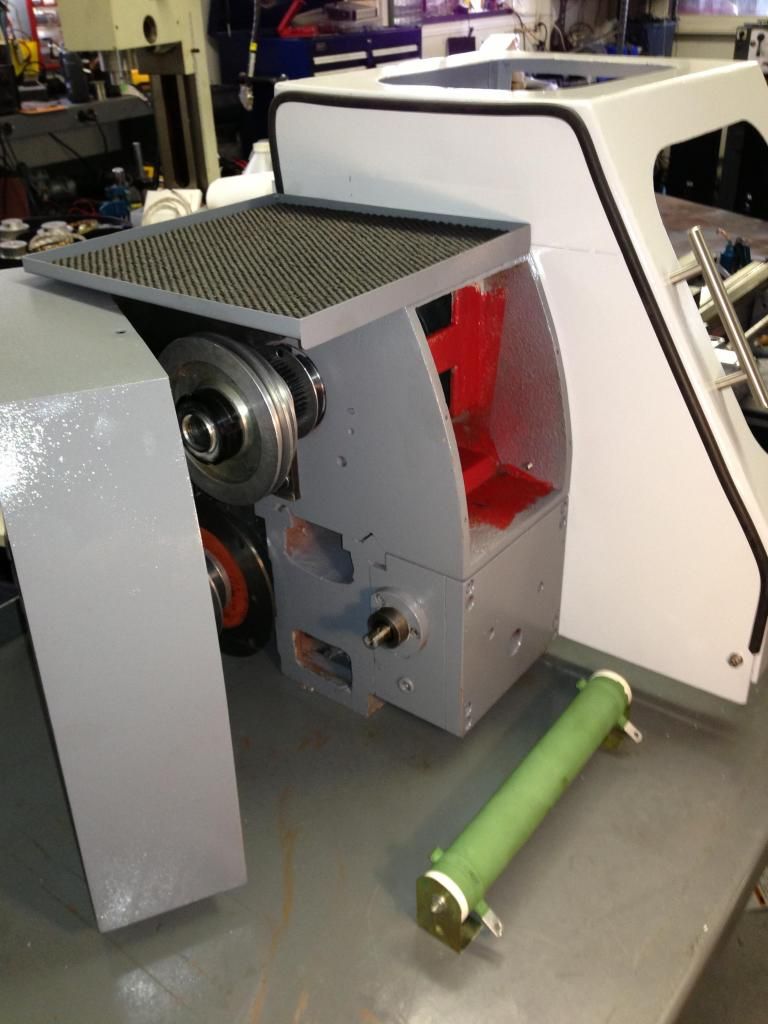

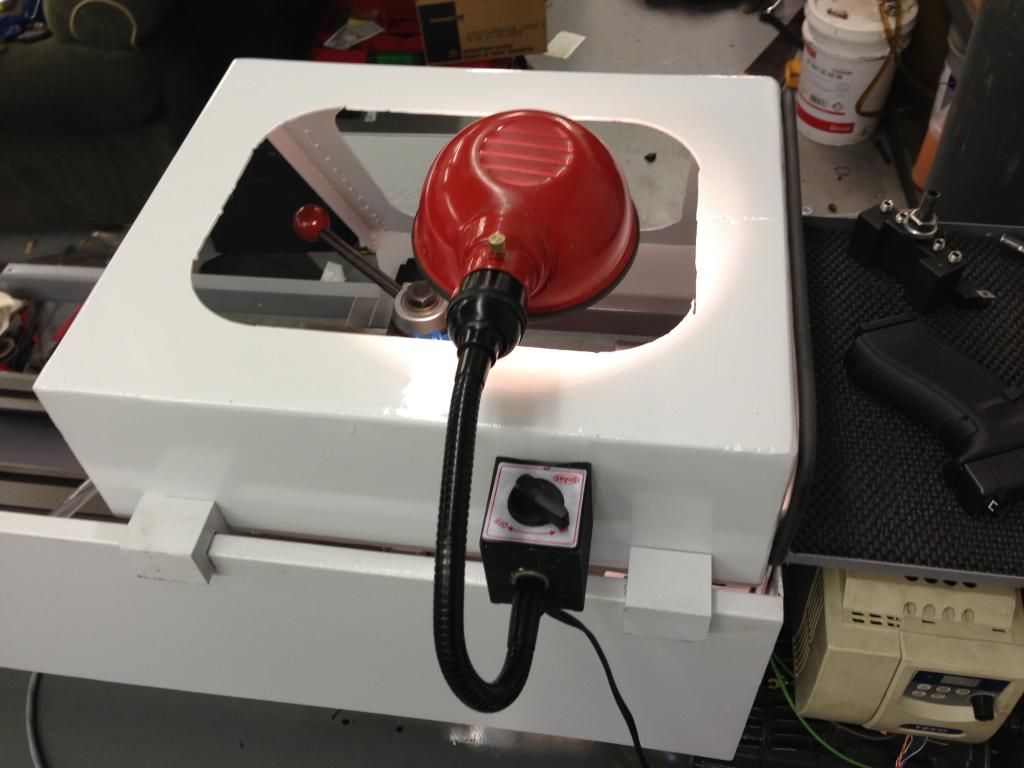

Here is a quick video of the current progress as I get ready for paint. Made a little tool tray for the top of the lathe.

Tool tray G0602 CNC - YouTube

-

04-09-2013, 09:02 PM #93

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Got some paint put on last night. What a PITA. Dark grey and light grey.

-

04-09-2013, 09:29 PM #94

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 41

Absolutely perfect if you ask me!

Not that I'm anybody, but in all seriousness, nice color combo as it looks professional as hell.

Dave

-

04-09-2013, 09:46 PM #95

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Thanks Dave, I just looked at what some other mfg's were doing for colors and copied them. (Haas). I wanted the inside to be lighter so it didn't turn into a dark hole if I mount a full enclosure. I may mount a light, doesn't seem to need it yet. I will see after I get the polycarbonate installed. I sprayed Rustoleum thinned with acetone. Seems to hold up very well, I use it on my shop benches and tables. You can get it in different colors by the gallon at HomeDepot for $25.

-

04-11-2013, 03:35 AM #96

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Here is today's progress. Woke up early around 4:45 AM and started fooling around in the shop. Found myself machining the tool post t-nut in a bath robe. Now there are a bunch of steel chips stuck to the robe. I left it out in the shop, If my wife saw it she would be pissed. At least I wasn't in my bare feet, I had some crocs on. I always try to have foot cover on when working with steel. I machined the tool post T-nut on the Jet bridge port clone using some of those cheap HF cutters. You know the set, don't try and act cool! I think I used the 4 flute 3/4" end mill. Cut whatever that steel was like butter. I was taking 1/10" DOC at 100%. After about 5 minutes I started enjoying the feel of the hot chips on my face. Kind of like being attacked by a swarm of bees's. After a bit of trial and error I got the nut fitting well in the slot. The paint is looking good and is starting to harden up nicely. I turned the heat up in the shop to 85 deg F last night. Got all of the gibs oiled up and adjusted nicely. I guess its time to start on the electronics cabinet! FUN FUN.....NOT! Where the heck is my window molding trim?

T-nut - YouTube

-

04-12-2013, 03:01 AM #97

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

-

04-12-2013, 03:21 AM #98

Plastic

Plastic

- Join Date

- Apr 2013

- Posts

- 0

That really is a beautiful machine. The 5/8 rod out segment is a great idea I think you'll see others (and myself) use.

-

04-16-2013, 10:40 PM #99

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 30

-

04-16-2013, 10:55 PM #100

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 101

First it was a gun and now a grenade. Any intruders are in for a BIG surprise. :devious:

Similar Threads

-

Grizzly G0602 10" x 22" Lathe Conversion

By derekbackus in forum Vertical Mill, Lathe Project LogReplies: 145Last Post: 01-29-2019, 09:29 PM -

King 10x22/Grizzly G0602 CNC conversion with full enclosure

By ZincBoy in forum Vertical Mill, Lathe Project LogReplies: 5Last Post: 01-16-2013, 08:35 PM -

Grizzly's G0602 10x22 Lathe

By cobmachine in forum Benchtop MachinesReplies: 21Last Post: 02-01-2011, 03:26 AM -

Grizzly G0602 10x22 Lathe Conversion

By Steelpolish in forum Vertical Mill, Lathe Project LogReplies: 56Last Post: 01-21-2011, 11:04 AM -

About to pull the trigger on a Grizzly G0602

By akschu in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 08-28-2008, 09:36 PM

Reply With Quote

Reply With Quote