If you're planning to buy an Obscidian CNC machine please read this first.

I usually don't write reviews, and I expect nothing to come of it, but I do want people to be educated on what Obscidian CNC is selling

I ordered my machine on November 20, 2022 I received the machine May 31, 2023

Since receiving it I've had more issues than I can count The machine did run when it first arrived but I'll go into more detail in the paragraphs below.

Obsidian CNC has been unwilling to work with me to fix many of these issues and is assigning all the blame to damage caused by UPS during delivery. Most of these would not be immediately visible, and UPS won't wait around fro you to bring the machine into your shop and power it up run tests. To put all the blame, delivery tells me they do no care about their customers' experience.

Electrical issues

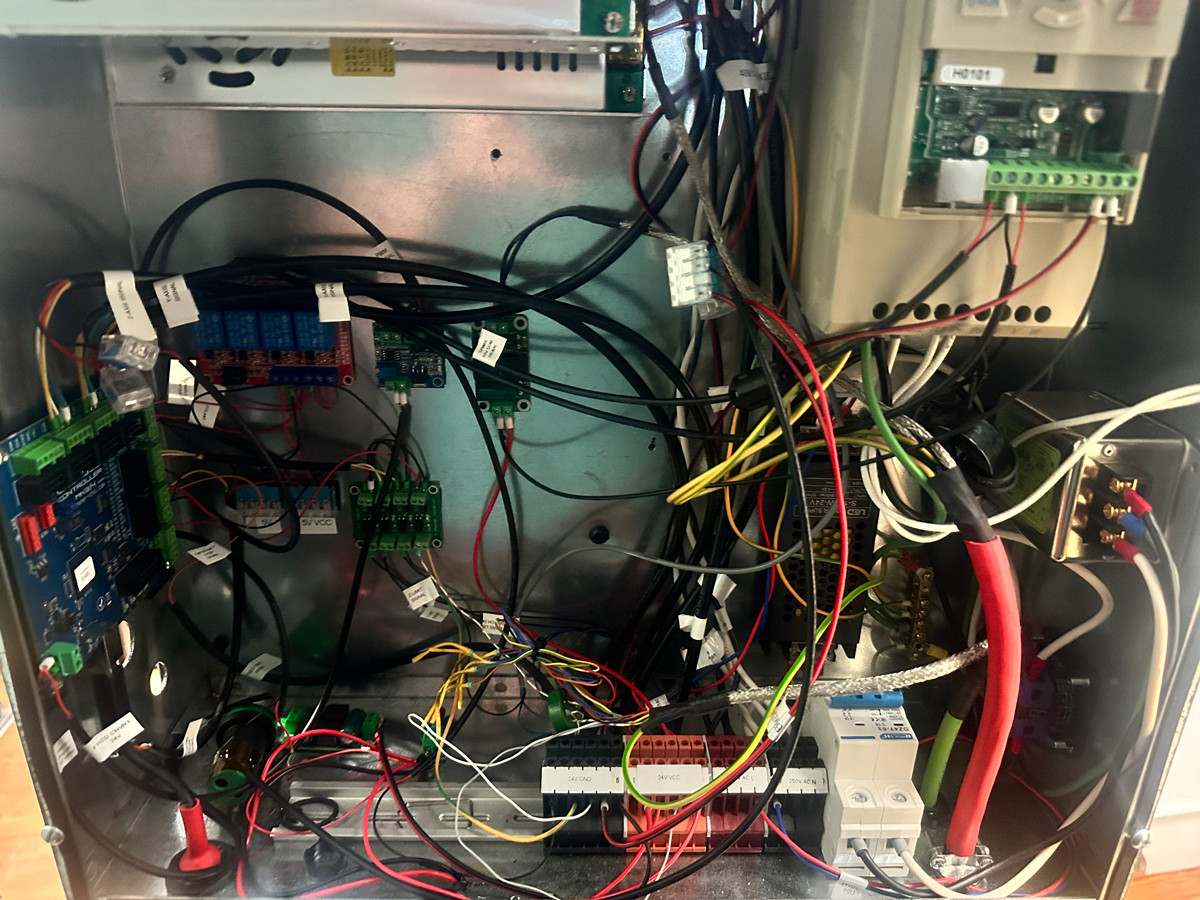

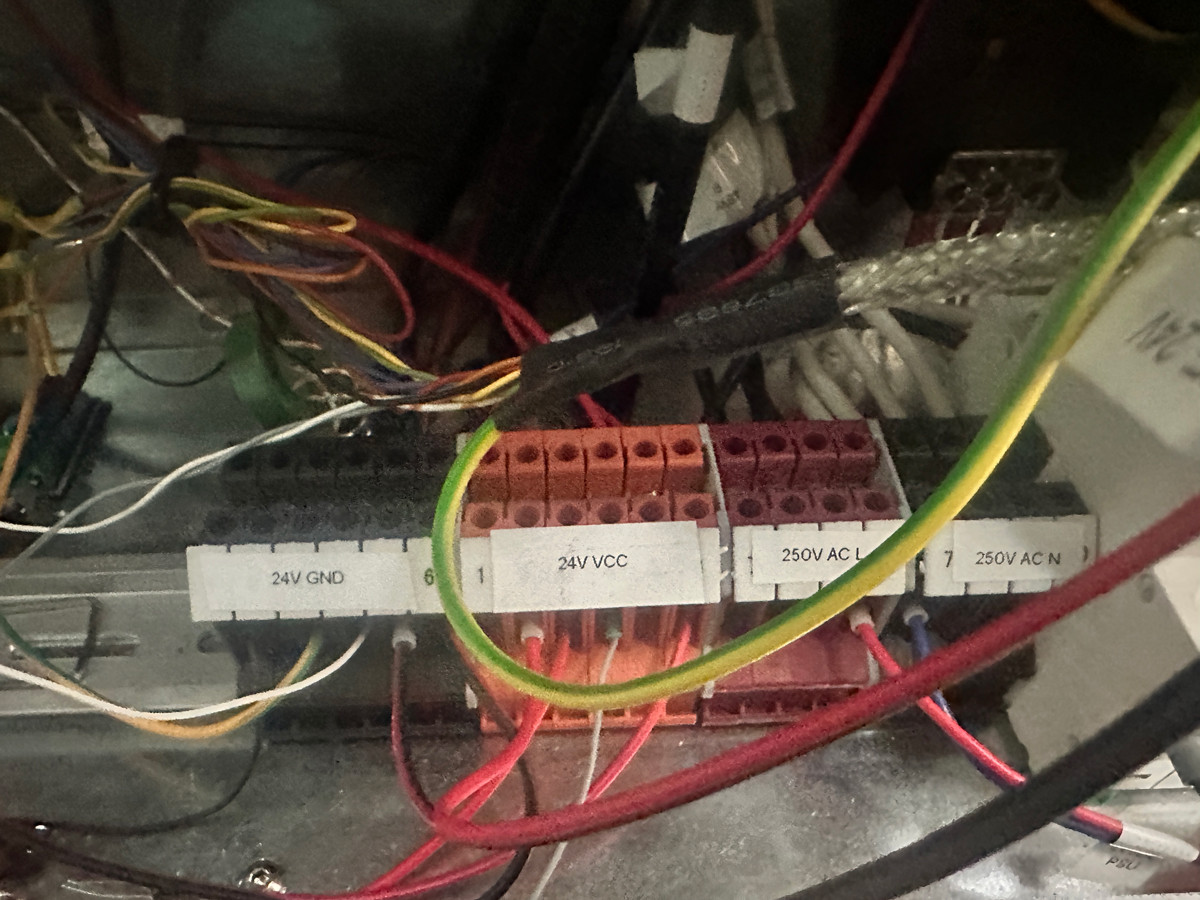

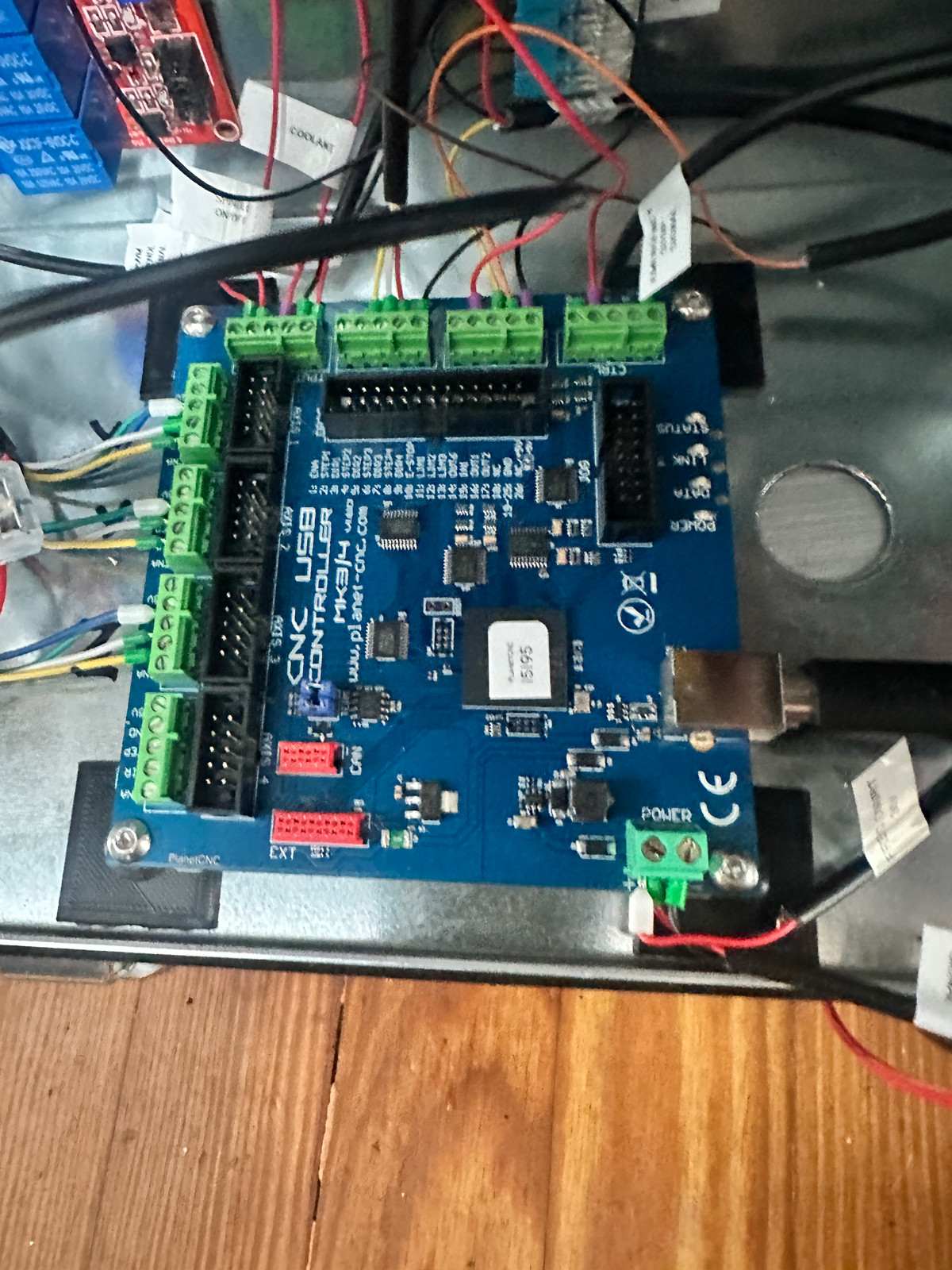

The Control box wiring is in terrible shape and very poorly executed. Since owning the machine only briefly, I've had several electrical issues, from shorts to poor signal output to the motors. None of the wires are shielded the ferrites are improperly sized. The emergency stop does not work, the solenoid for coolant does not work. And many of the wires are simply to small for the load. You can't use 20 gage wire to run your main 240v into a 10-gang. It's dangerous. I'm continuing to have issues with the Z-axis motor. They replaced the $500 VFD Spinogy recommends run their spindle with a $60 stepper online VFD. Voiding the warranty on the $3000 spindle I purchased separately for this project. They kept the Spinogu VFD and did not return it to me. The Spindle brake does not work with the cheap VFD they chose. The wires for the X and Y proximity sensor have sheered because they were run through holes that were not deburred. In fact, none of the machine parts mounting and through holes were deburred.

Here are some photos of the control box from their factory. The should be embarrassed but see no issue with how this is has been wired.

Mechanical issues.

Besides the issues with the Z Servo itself, the bearings in the Z motor mount are blown out. There are several bolts missing that hold down the linear rails, and there is one bolt missing on a X-axis guide blocks. I understand this is a hobby level machine but every part from the rails to the ball screws are the absolute cheapest option available on the market today. I spent $5600 on the machine but I also had to buy the servos, Spindle and VFD seperately. The linear rails and guide blocks are not up to the task for the size and weight of this machine. The ballscrews are mounted fixed-free and cause vibration in the machine even at moderate speeds. There is quite a bit of backlash on Y, I supect, it's partly because All the ball screws on this machine are Fixed-free. I know this is great way to save $50 but it also puts load on the the fixed side bearings and it's fairly obvious why the bearings blew out on the first run of the machine. The Linear rails on all three Axis are wavy and not flat. I didnt immediately know why until I took the machine apart. What they're calling epoxy granite looks like Pea gravel and sand with a thin layer of epoxy to smooth things out. Certainly this does not have the needed hardness to properly align and load the linear rails and the surface beneath the rails has begun to crack and disintegrate. On the X Axis the rails are fixed to the aluminium bed. The issue here is how the where tapped I'm guessing they barely have 50% thread. I cannot correctly torque the rail on X because the tapped holes strip before I reach the specced (5.1Nm) torque required.

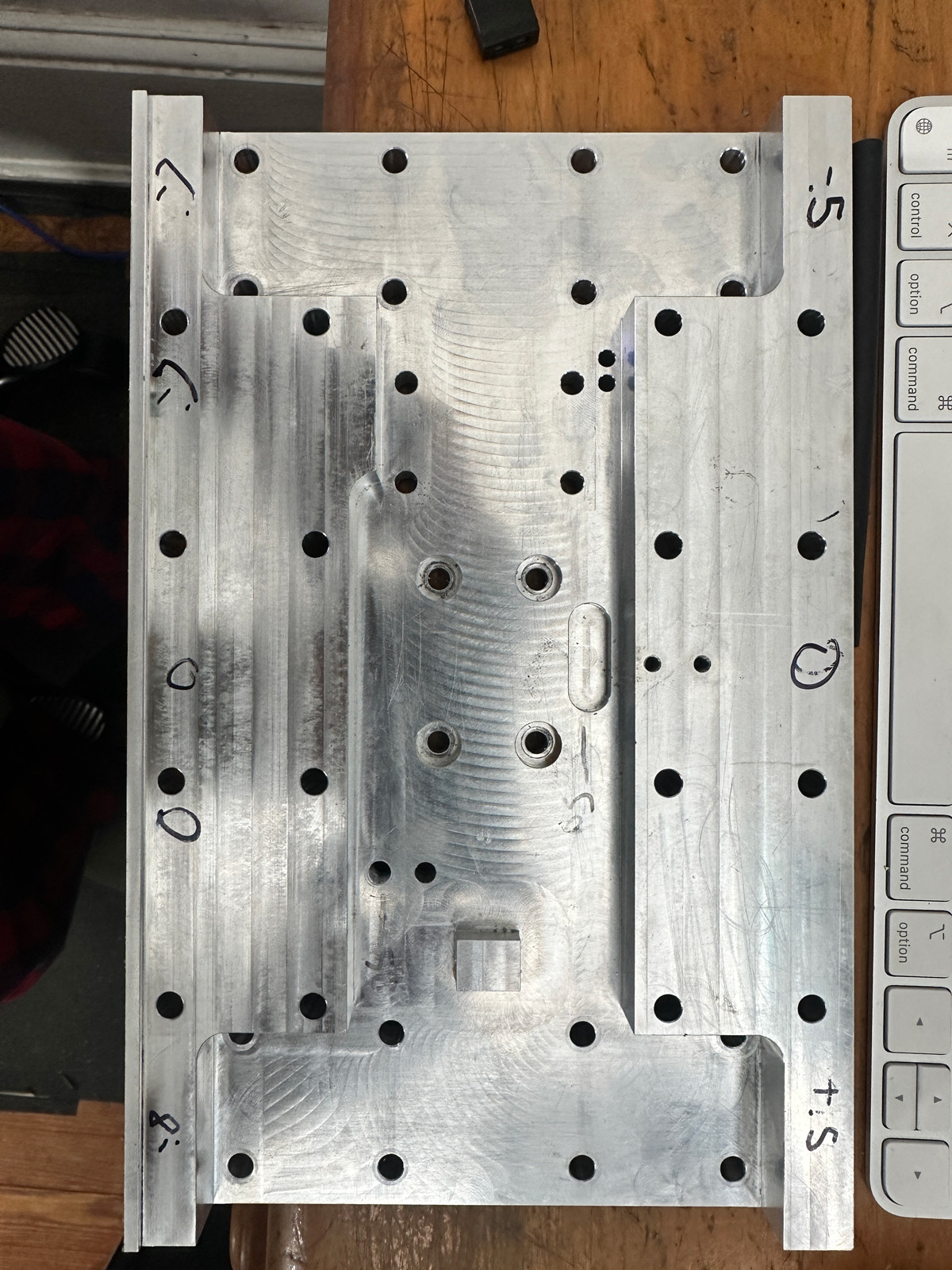

Here are the plates the guide blocks attach to. The first is XY. On a surface plate I measured flatness along the linear guide parallel. with the center set to you can see the bottom left build block mount is 0.8mm low and the bottom right is 0.5mm high. First his makes the. guides run terrible but depending on where you are it changes the height of the milling plate surface. I believe both of these parts should be redone to a tighter tolerance

Structural issues

I mentioned above that the material used is not actually Epoxy granite and appears to have a lot of hollow cavity space either from using the wrong materials or not pressurizing it correctly as it cured. Im no expert but I do know that there should not be a bunch of hollow spaces 1mm below the surface, The surface looks like it's been bondoed smooth.

Checking the Z column with a machinist square. The column is leaning 2°. This makes it impossible to tram the spindle dead flat. The column will need to be removed and correctly leveled.

On test cuts I did with the machine over several day it is not capable of cutting a circle maybe it's the backlash or the blown out bearings or maybe the poorly machined surfaces, I dont know. and basically I've given up trying to track down all the issues. I've tried to stay positive, but the problems have continued to accumulate. With no help from Obsidian I plan to rebuild the machine at a considerable expense to myself.

Thread: Obsidian CNC review

Results 1 to 4 of 4

Threaded View

-

08-15-2023, 03:09 PM #1

Member

Member

- Join Date

- Oct 2022

- Posts

- 10

Obsidian CNC review

Similar Threads

-

Quick CNC review- buy Chinese CNC

By shonir in forum Chinese MachinesReplies: 34Last Post: 11-23-2023, 03:29 AM -

Cnc Router USA End User' review about China cnc sales

By allencncrouter in forum Chinese MachinesReplies: 0Last Post: 08-28-2018, 02:43 AM -

Video Review of Chinese CNC Router from Unique CNC

By dmoore in forum Chinese MachinesReplies: 5Last Post: 02-14-2018, 10:16 PM -

Plasmaroute CNC Blaze2 CNC machine review

By InflatibleDog in forum CNC Plasma / Oxy Fuel Cutting MachinesReplies: 402Last Post: 06-30-2017, 04:02 PM -

CNC Masters Review

By alexdbz4 in forum Drilling- and Milling MachinesReplies: 3Last Post: 06-15-2012, 06:18 AM

Reply With Quote

Reply With Quote