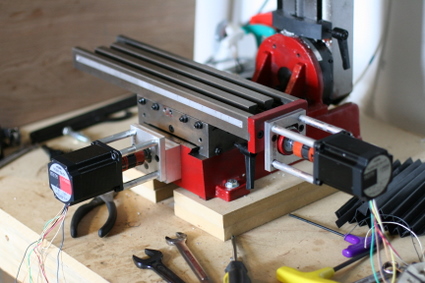

My CNC conversion(http://biobug.org/machine-shop/mill) is now 2/3 operational - I'm using the X and Y to machine parts for the Z. (I'll go nuts soon, being a manual Z axis is a pain when a gib decides to bind.)

I've got the typical binding at the extremes of travel. What's the best solution to this? I've seen fignoogle's acetal gibs, and gib lapping, and brass gibs all done. What's the best solution? I want the binding taken care of ASAP.

So - brass gibs or lapping? I'm tempted to try the aluminum polish method since I can use a simple gcode file to run the motors back and forth as much as needed.

Quick details:

I based my conversion mechanically on Hoss's. (hossmachine.com, dxfs are on cnczone)

Nook ballscrews/ballnuts.(single per axis)

240oz vexta steppers -bipolar series for now

modded atx power supply - 12V to motors for now

I built a set of Embeddedtronics microstep contollers for each axis - currently using 8 microstep mode for .000125" per microstep resolution. Final cost - about $70.

Results 1 to 5 of 5

-

04-13-2007, 06:52 PM #1

Registered

Registered

- Join Date

- May 2006

- Posts

- 7

Tweaking my X2 CNC conversion (help with gib binding!!)

-

04-13-2007, 08:10 PM #2

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 430

i just didi this yesterday on my x2, i removed the x table and just took some sand paper and rubbed down the ends of the dovetail. i still have to do the y axis. its better but i could do some more sanding on it.

-

04-13-2007, 08:45 PM #3

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 534

I'm curious about this because I have some flex in my system. It's 0.006" with the Gibb strips set real tight. I can't get more than that.

If I set the Gibbs loose it drops to 0.0015", so something is springy.

I thought about trying a slide oil with an anti-stiction component, but doesn't that invite uncontrollable judder?

I'm thinking I may set the Gibbs tight, make the final cut light and take up the 0.006" whenever a screw changes direction.

I made this little bobbin desite much backlash on the lathe cross slide, simply by adding a compensation when it changed direction. BUT, would it work on a mill?

-

04-14-2007, 10:49 AM #4

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 607

I just switched out the gibscrews with nylon ones. This might not be good when working with harder materials, but it works just fine when working with alu. This ensures a good amount of pressure on the gibs and they can move a little so that it doesnt bind.

-

04-15-2007, 07:49 PM #5

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Hey will,

I just tried something today. I had the gib screws a little on the loose side

so the Axis' would run freely without binding up the steppers but it left the Axis'

a little sloppy. I installed some very stiff 3/16 springs ahead of the gib screws and readjusted them. It took out the slop and the steppers still move freely. Lets it give a little where it needs to. This is just a quick fix, I need to tear it down and lap them all in properly. Should have done it before the CNC

conversion but I was too anxious to get it running.

Small Parts Inc. has some stiff little springs with 50 lbs/in. (CSX-0088)

http://www.smallparts.com/products/d...ions/g28%2Ecfm

Here's a couple pics

Hoss

Similar Threads

-

Series I, BOSS Z-Axis Binding - Help

By split63 in forum Bridgeport / Hardinge MillsReplies: 12Last Post: 06-26-2006, 04:16 PM -

Tweaking a Fadal

By krustykrab in forum FadalReplies: 10Last Post: 05-15-2005, 06:22 AM -

binding?

By bobleecnc in forum 80/20 TSLOTS / Other Aluminum Framing SystemsReplies: 4Last Post: 04-05-2005, 02:32 AM -

Excellon and Gerber tweaking

By Rhodan in forum Uncategorised CAM DiscussionReplies: 1Last Post: 04-26-2004, 01:49 AM -

Binding - mini lathe

By JFettig in forum Mini LatheReplies: 6Last Post: 03-14-2004, 10:37 PM

Reply With Quote

Reply With Quote