This is my first post here, so go easy on me

I've been wanting to get a (hobby) CNC mill for while and have been keeping an eye on the market for about a year now, reading and learning while trying to decide what machine to buy. The CNC 3040 or 6040 seemed great at first (and within my price range) but I was put off by the multitude of problems people were having with the controllers, the cabling, and the underpowered spindle. However, most of this now seems to have been resolved with the new controller, VFD and spindle that ships with the YooCNC versions of these platforms, and as luck would have it I also happen to have the funds to make a purchase.

I'm still trying to decide between the 3040 and 6040 models - with the 3040 (£650 shipped) being exactly half the total cost of the 6040 (£1300 shipped) - an annoyingly tempting price differenceI'm also worried that the 6040 is going to be too large a machine for my already somewhat crowded workshop, with a footprint close to 1m3.

The primary uses I see for a CNC are circuit board making, front panel engraving, making small parts and spares as well as mounting elements for various tinkering and repairs that I'm always up to - all of which should comfortably fit on the 3040's smaller table. On the other hand I also want to use the machine to experiment with engraving photos and other "art" type work (2.5D engraving, sign making, paper cutting etc) and since I already have a couple of A2 inkjets, and an A0 plotter, I'm spoilt with being able to work LARGE - I fear that for artistic use the 3040 will simply feel too small. Anyway, this is a decision I have to make for myself (I'm strongly leaning towards the 6040 btw), and it's not the reason I'm posting here - though if you have anything to add on the subject I'd be interested in your opinion.

Once I do get a CNC mill, one of the first projects I'd like to use it for is to build a 3D printer - the order seems to make sense to me as you should be able to make most of the structural components for a 3D printer on a CNC mill (from perspex or aluminium), whereas the reverse would be impossible. I know that many feel that the true genius of a 3D printer is its potential ability to "self replicate" - and I can see the beauty of this argument - but I'm more interested in practical use. If a 3D printer is to have any value to me it has to be able to produce reasonably high resolution output (100 microns or better), and be fairly reliable. That pretty much excludes anything I could design and build myself from scratch, so I've looked around for kits, plans and cut/part lists for proven designs.

Although I've found a couple of very promising design candidates (the "Ditto" and the "Ultimaker" for example), I've stumbled upon a bit of a snag: all the cut lists I've found are intended to be run on a laser cutter and contain many radii(?) which aren't possible to replicate on a CNC mill, particularly for the "T-slot" style fixing system of the main body panels which seems to be so popular.

TL,DR:

Does anybody know of a set of plans, with parts and cut lists, for a 3D printer that is suitable for making with a CNC mill, and which has the potential to reach 100 micron resolution? If not, do you have any suggestions for where I could go to find more information on the subject?

Any input appreciated!

Results 1 to 6 of 6

-

05-05-2013, 08:45 PM #1

Registered

Registered

- Join Date

- May 2013

- Posts

- 49

Millable 3D printer plans/cutlist

Millable 3D printer plans/cutlist

-

05-06-2013, 05:13 AM #2

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

I can't comment on the 3D printer side of things, but so far as the 3040/6040 goes, I see the 3040 more as a companion machine for smaller work, in addition to the 6040 which is the main. I would be very surprised if you didn't outgrow the 3040 pretty quick, unless you really don't see yourself doing anything of larger dimensions?

To my mind, if you are only buying one CNC machine, the 3040 would be false economy, for the reasons stated above. Upgrading to a 6040 later, becomes a costlier exercise, as you are left with a machine you likely use increasingly less to the point it gathers dust. I would go the 6040 route if there was the slightest desire, or even the remotest chance to do larger work.

cheers, IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

05-06-2013, 11:47 AM #3

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 97

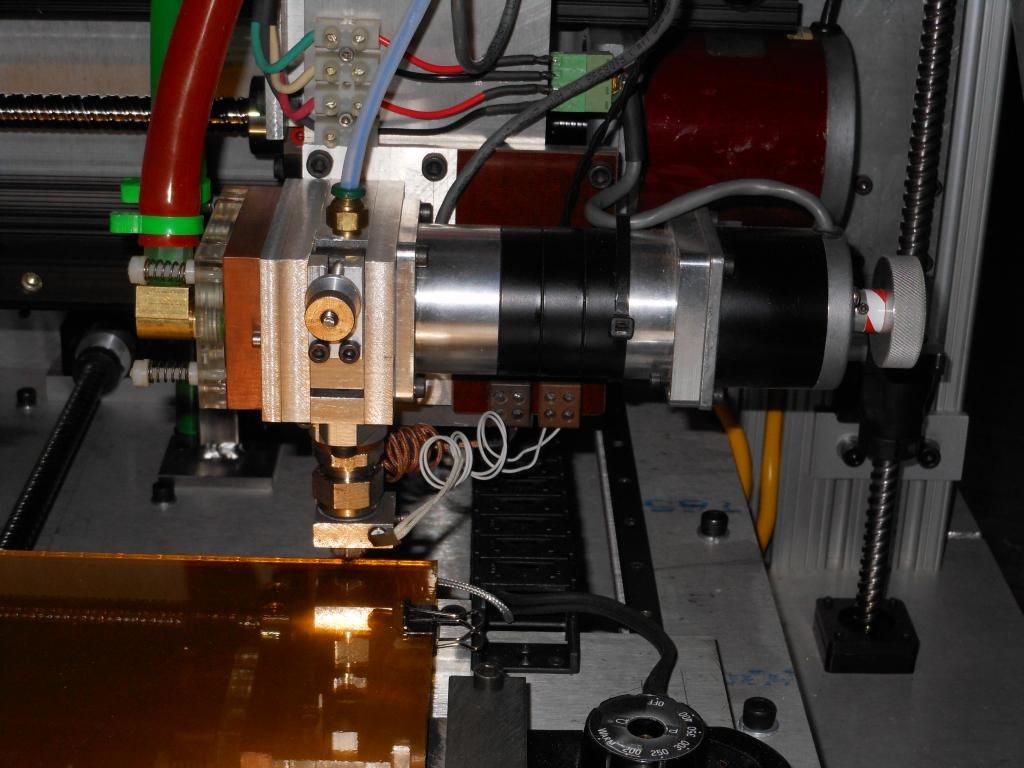

No plans but hear is one i built

Two ways to go about it very light mass light structure or the way i did heavy mass and very strong structure

Two bad videos https://www.facebook.com/photo.php?v...74382398743664https://www.facebook.com/photo.php?v...69305644303332

Two bad videos https://www.facebook.com/photo.php?v...74382398743664https://www.facebook.com/photo.php?v...69305644303332

-

05-07-2013, 02:38 AM #4

Registered

Registered

- Join Date

- May 2013

- Posts

- 49

@aarggh: Thanks Ian - I know what you're saying makes sense. Unfortunately. :| It would be nice to get away with paying £650 less and still be able to do most of the things I mentioned in my post, but I know the size restriction will soon start to annoy me. Even the idea of leapfrogging via a CNC mill to a 3D printer depends on the CNC being able to cut fairly large (and thick) panels - if the side panels had to be made on a 3040 the resulting 3D printer would have to be made so small that it would be almost pointless.

@dick cnc: Wow, that's a beast! Considerably bigger (and more expensive I'm sure) than what I'm considering, but looks very nicely put together. How much did that cost to build? I guess from the hot-plate and the shiny Yoda that you're printing with ABS? How did you get the different colours? Your design differs from what I have in mind in that yours is built with an open frame, and based on off-the-shelf aluminium profiles, which seems a fairly common approach, whereas I'd like to use cut sheet panels for the base, sides and back (see the Ditto and Ultimaker models linked in my previous post). I imagine this has benefits in rigidity and ease of assembly (the panels should square up automatically) and, perhaps more importantly, it would be the perfect use for a CNC mill As a bonus it should make it a doddle to attach some hinged acrylic windows, protecting the print from sudden drafts and temperature changes which I understand can cause distortions.

As a bonus it should make it a doddle to attach some hinged acrylic windows, protecting the print from sudden drafts and temperature changes which I understand can cause distortions.

To rephrase my initial question a little bit: Does anyone know of a good quality 3D printer kit that would work well inside a box style chassi?

-

05-07-2013, 02:57 AM #5

Registered

Registered

- Join Date

- May 2013

- Posts

- 49

Actually, having just posted that I realised what a stupid question that was - I already have two ideal candidates for "a 3D printer kit that would work well in a box type chassi": the Ditto and the Ultimaker!

Maybe the best way forward is to edit the plans for one of these to use a different assembly method instead of the "T-slot" type. Only problem there is I fear I'm too inexperienced to deal with the inevitable snags, and getting the plans adapted may end up being a much bigger project than I have time for. I do know my way around CAD software to some extent, but I've never used it to design anything for CAM output. I get the concepts of toolpaths, cut rates and spindle speeds, and even G-code doesn't look too intimidating(!), but without a set of plans from someone more experienced I doubt I'd be able to assemble a working machine. Any thoughts?

Maybe the best way forward is to edit the plans for one of these to use a different assembly method instead of the "T-slot" type. Only problem there is I fear I'm too inexperienced to deal with the inevitable snags, and getting the plans adapted may end up being a much bigger project than I have time for. I do know my way around CAD software to some extent, but I've never used it to design anything for CAM output. I get the concepts of toolpaths, cut rates and spindle speeds, and even G-code doesn't look too intimidating(!), but without a set of plans from someone more experienced I doubt I'd be able to assemble a working machine. Any thoughts?

-

05-07-2013, 05:42 AM #6

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 317

Make sure you know how the parts fit together before you start editing them. Have you looked at any delta style printers? Many of them are doing very well and if someone took the time to build one out of quality materials and actually build it with some strength you could attach a nice extruder on the end and do amazingly fast prints with it. Some of the current deltas are the Rostock, Rostock Max, and the Kossel. Newest additions so far have been using magnets to connect the arms instead of traxxas ball joints but that would probably not work if you wanted to mount a full extruder on the effector.

Similar Threads

-

3D printer

By automationtechinc in forum Automation Technology ProductsReplies: 1Last Post: 01-23-2014, 04:55 PM -

Anyone have an SLA printer?

By mcphill in forum North America RFQ'sReplies: 0Last Post: 10-19-2012, 03:03 PM -

Converting a laser printer into a 3d laser printer

By João Carimo in forum Uncategorised MetalWorking MachinesReplies: 22Last Post: 04-30-2011, 09:56 PM -

CUTLIST

By BOBINETTE in forum Mach MillReplies: 7Last Post: 10-04-2009, 12:04 PM

Reply With Quote

Reply With Quote