Economic manufacturing of lot size 1

Current discussions about manufacturing focus on the greatest possible transparency of know-how transfer along the process chain as well on the topic of process safety. Variance in parts is yet another challenge, particularly in tool and mold forming, and even a lot size 1 needs to be manufactured economically. Tools need to be reassembled continuously, depending on the parts - interfaces for efficiency are largely given through transparent tool organization and the simulation of the NC program with real tool data.

Guaranteed collision-proof

ZOLLER offers solutions for faster and guaranteed collision-proof manufacturing through efficient tool management solutions, high-precision measuring machines and special measuring programs, for example, »contur«, »tool realityCheck« or the »3dScan«.

Clearly defined tool assembly

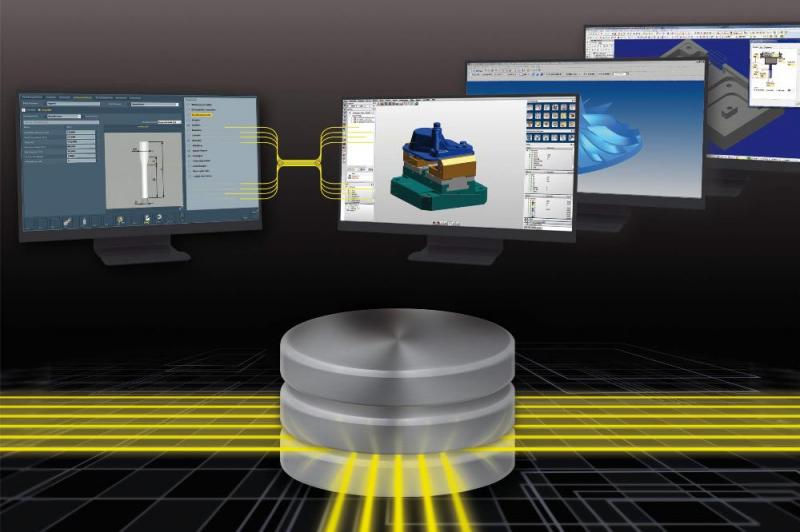

The basis for programming a true-to-life milling strategy is given by the clearly defined tool assembly through individual components in the parts list of the tool management system. By using ZOLLER with interfaces to all common CAM systems, this dispenses with duplicating data. Transparency and a clear definition of the tool data are also ensured.

Simulation with true tool data

To give real-time simulation, the »3dScan« can then be used to determine the exact contours of all rotation-symmetrical tools and transferred to the CAM system.

Simple target-actual comparison

The »tool realityCheck« is a further variant for ensuring that the tools accurately meet specifications prior to their use. This measuring program performs a contour scan and target-actual comparison quickly and simply and compares the tool used for the CAM system and the simulation with the actually existing tool. You can't have more safety!

Defined radii for maximum quality

To check the quality of the radius tools used, radii can be scanned fully automatically and with micro precision with the »contur« measuring program as well as checking their quality and contour fidelity.

If everything is set to "Go", the actual tool data for the machine are provided in a control-specific manner - an entirely process-safe and efficient procedure throughout.

All from a single source

ZOLLER offers everything that is necessary from a single source, from presetting and measuring the tools, to capturing the true data, through to interfaces for virtually all CAM systems - a major benefit for the user. This means manufacturing with less effort - and greater efficiency.

Germany

Germany