The three machines, CHP, CHC and CHF, are each available in the two versions 840 and 1300. Vollmer has equipped all machines with a new operating concept, which is the multifunction hand wheel for intuitive operation. The machines with their accompanying services bring benefits to companies which process wood, plastic, aluminium or metal during production, namely saw mills, sharpening services, as well as small-batch manufacturers.

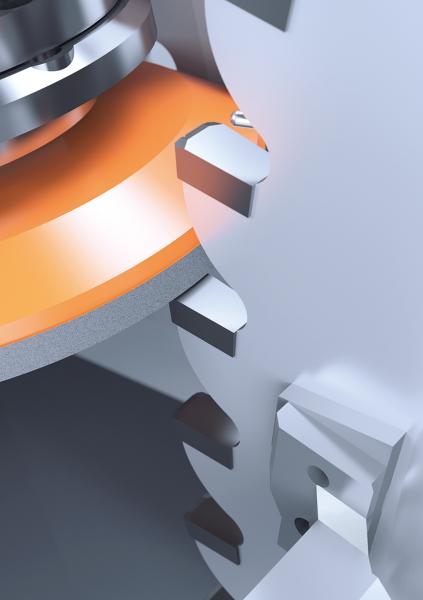

To mark the start of 2015, Vollmer will shortly be presenting half a dozen new sharpening machines designed for carbide-tipped circular saw blades. The sharpening machines CHP, CHC and CHF are each available in the versions 840 and 1300, figures which stand for the diameter of the circular saws that can be processed with the machines. A new feature for all machines is the operating concept with the multifunction hand wheel, which significantly simplifies and speeds up the control and programming of the sharpening process. Thanks to the control exercised by the hand wheel, the axes can be selected and moved by only one module, which prevents the possibility of incorrect operation. The hand wheel is also used as a potentiometer in order to carry out speed adjustments in automatic mode.

A quartet for the circular saw hook and clearance angles

Both sharpening machines CHP 840 and 1300 are universal sharpening machines for hook and clearance surfaces of carbide-tipped circular saw blades which are suitable, with four CNC-controlled axes, for the complete machining of all commonly found tooth geometries. In one cycle, they also machine saws with an axial angle and group toothing. A motorised hook and clearance angle adjustment automatically allows the rapid switchover from hook to clearance surface. The adjustable grinding barrel for chip breaker machining ensures more flexibility in the machining of circular saws for metal cutting. Software for negative hook angle geometries and chip breaker machining is available as standard. In addition, the machine can be equipped with an optional hollow face grinding device for machining hollow face saws. The CHP series is principally suitable for workshop-oriented sharpening of circular saw blades for cutting wood, aluminium, plastic and metal. Vollmer machines can be universally used in saw mills, by sharpening services and for small-batch manufacturing.

The Vollmer CHC 840 and CHC 1300 machines are the two "flexible sisters" of the CHP series. Specifically conceived for the particular requirements of sharpening services and saw mills, the CHC series is designed for sharpening carbide-tipped circular saws economically. Also fitted with four CNC-controlled axes, it is suitable for the complete machining of all commonly used tooth geometries in one cycle and, like the CHP, can be equipped with a hollow face grinding device.

CHF 840 and 1300, perfect for side machining

The CHF grinding machine in the versions 840 and 1300 uses five CNC-controlled axes to machine the tooth sides of carbide-tipped circular saw blades. All commonly used angles are ground in only one cycle, even on saws with group toothing. Oscillation grinding as standard allows a high level of material removal, such as is required in production operations or in servicing during tooth replacement. The saw mill industry as well as companies that process wood, plastics, aluminium and metal use the Vollmer machine for side grinding. The machines from the CHF series adjust the angles without assistance, even the hook angles, and detect the tooth pitch automatically.

"For our new sharpening machines we provide numerous services such as consultation and training, as well as financing options," says Jürgen Hauger, Head of the Sales Division in the Vollmer Group. We also support our customers throughout the entire service life of the machines, with services for maintenance and corrective repair, for which we operate twelve of our own Sales and Services branches worldwide."

VOLLMER WERKE

News

Three times two cutting machines for circular saws

Responsible for the content of this press release: VOLLMER WERKE Maschinenfabrik GmbH

|

VOLLMER

|

VOLLMER

|

VOLLMER

|

VOLLMER

|

VOLLMER

Contact

VOLLMER WERKE Maschinenfabrik GmbH

Ehinger Straße 34 88400 Biberach an der Riss

Germany

Germany Route planner

Route planner