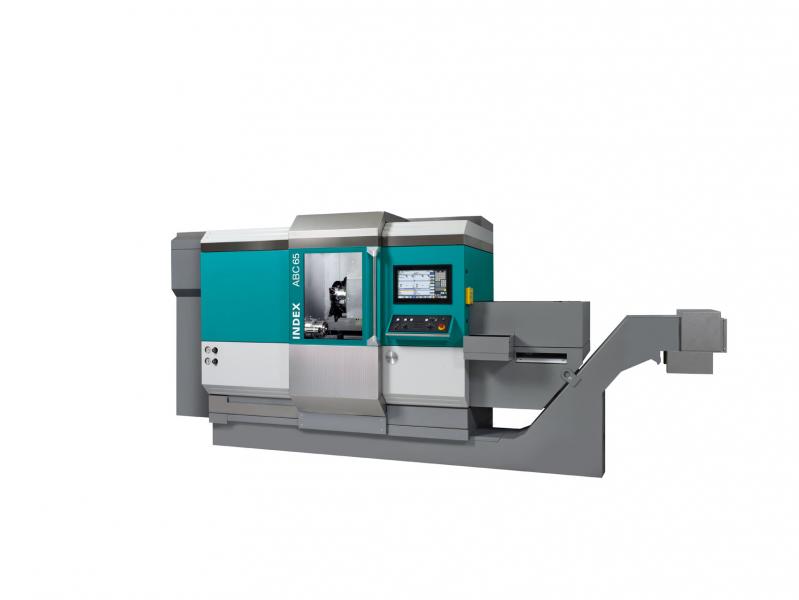

Developed for high productivity and precision, the newly developed CNC automatic lathe INDEX ABC65, successor to the successful INDEX ABC series, uses innovative technologies and proven components from the current INDEX lathe portfolio not only to finish typical machine-turned parts, but also to produce significantly longer and more complex workpieces in large and medium quantities at almost the same footprint.

The vertical design of the machine with a setup-friendly work area not only provides good conditions for unobstructed chip flow but also significantly better ergonomics which facilitates setup operations. The basis for this is a vertical cast machine bed mounted on a heavy machine base, whose damping properties are prerequisite for high-precision cutting. With two tool turrets, a main spindle with C-axis and 65 mm bar capacity (6,000 rpm, max. 35 kW and 120 Nm) and a swivel counter spindle with C-axis for extensive rear end machining, the ABC65 offers high production rates at only 5,5 m2 footprint (without bar loader) for CNC automatic turned parts up to 250 mm in length and also geometrically complex workpieces.

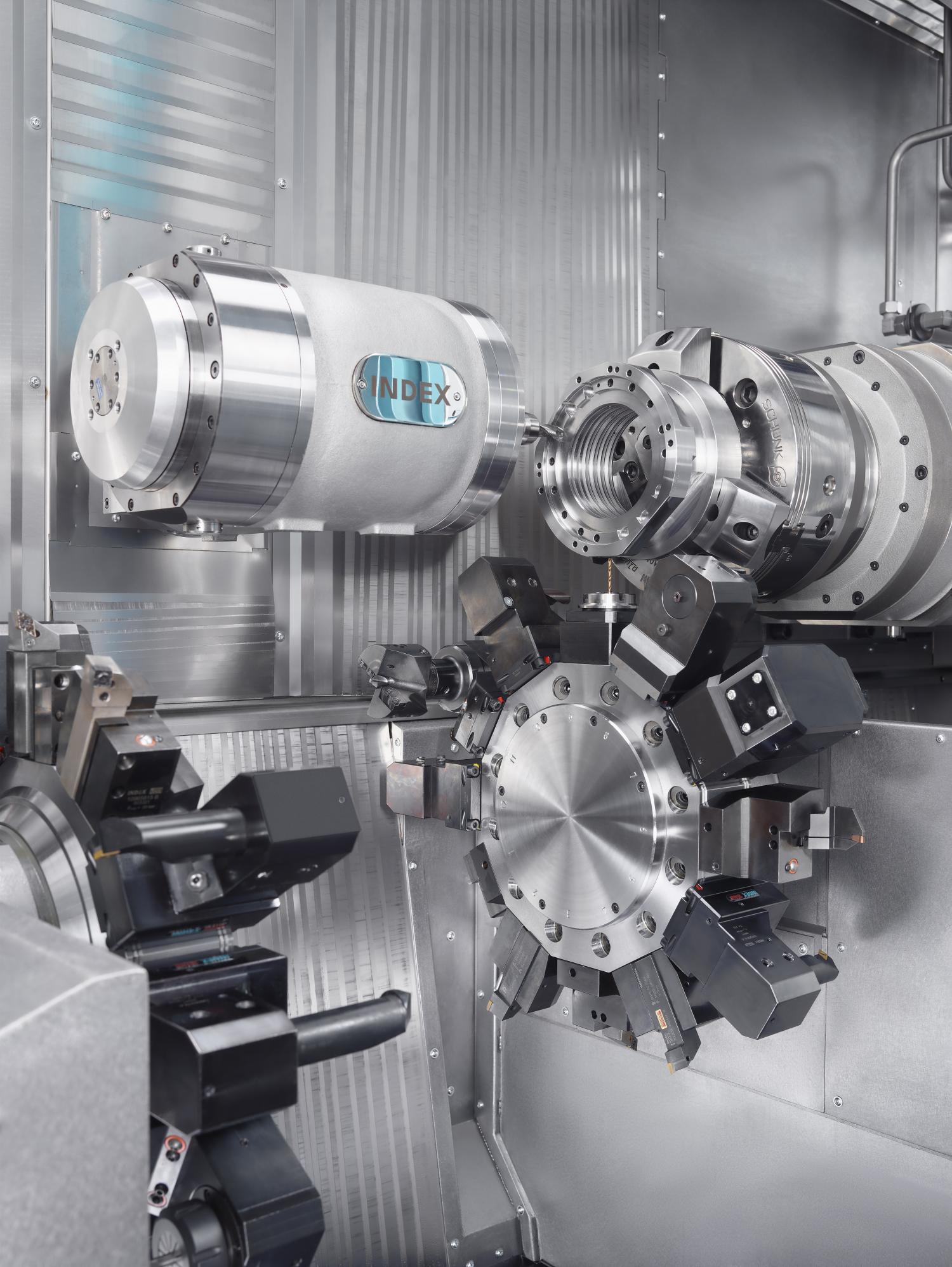

The upper tool turret has 10 stations with slide travels of X=140 mm and Z=300 mm. All stations in the upper turret can be equipped with live tool holders on the ABC65. Turret indexing is designed as an NC rotary axis with a direct measuring system without mechanical lock, thereby allowing fast positioning of the turrets at any angle. This allows multiple tool assignments at each station, so that the upper tool carrier can be equipped with up to 20 tools.

The standard built-in Y-axis for the two turrets is formed by the interpolated movement of the CNC turret indexing H-axis and simultaneously the C-axis of the work spindle as well as the X-axis of the tool carrier. Through the combined motion in conjunction with the powerful tool drives (with max. 9 kW / 10 Nm / 12,000 rpm), the ABC65 provides a large Y-travel of +/- 50 mm = 100 mm for all turrets, e.g., to mill surfaces and grooves on workpieces or to drill axis-parallel off-center holes.

With the optionally available new “Dual Drive” system for the upper turret, two separate drive trains ramp up the speed for the next tool while still cutting with the current tool. The new tool is then indexed to the machining position at full speed. This not only reduces secondary processing times, the live tool holders also experience a significantly longer service life.

Apart from its function as a lower tool turret with 9 stations and identical functionality as the upper tool turret, the lower cross-slide with travels of also X=140 mm and Z=300 mm serves as a swivel counter spindle for rear end machining of workpieces. The swivel movement of the counter spindle is achieved via the CNC turret indexing axis (H-axis). As an INDEX innovation, the ABC65 thus provides a counter spindle with a C-axis that can be moved in three axes (X/H/Z), allowing unrestricted counter spindle machining at 6,000 rpm (max. 9 kW and 20 Nm) and 52 mm spindle clearance.

Lost heat that is generated in the spindles, the control cabinet and the hydraulic unit is dissipated from the machine by a central fluid circuit. A water interface integrated into the ABC65 allows two solutions to heat dissipation: either connecting to a local cooling unit or to a central cooling system.

For years, all INDEX machines have met the demand for reduced energy consumption. The latest INDEX control generation C200-4D sl, based on the Siemens Sinumerik 840D Solution Line, was complemented by an 18.5-inch wide-screen display with full multi-touch surface and new user-friendly features for the ABC65.

With this control panel, INDEX has succeeded in incorporating numerous rotary and touch buttons of the machine control panel directly in the screen. Thus, the new INDEX ABC65 is the first to display switches and buttons as active only that really apply to the current machine status and whose movements are released.

Germany

Germany