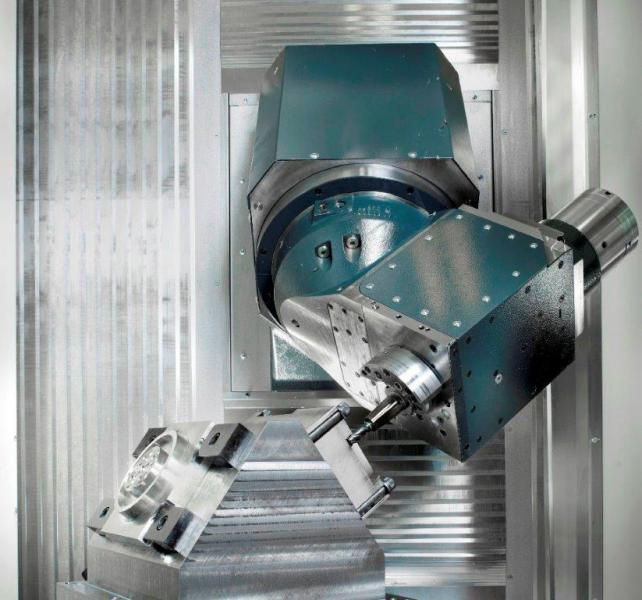

FP 4000: 5-axis machining centre with swivel-head unit

With the latest generation of the FP 4000 HELLER will be presenting highly productive 5-axis technology featuring a double Z-axis drive at the INTEC 2015 (Hall 2, booth E12/G11). With 5-axis simultaneous milling and in particular during production of sculptured surfaces, the machining centre ideally satisfies requirements relating to dimensional and contouring accuracy while maintaining excellent efficiency.

Equipped with a swivel-head unit, a pallet changer and based on the proven H series, HELLER is here focusing on uncompromising productivity, especially as the FP’s axis drives are generously laid out and the fifth axis in the tool forms the basis for process reliability and a high workpiece load.

With a workpiece load of up to 1,400 kg and the generous work area (800 mm in X and Y axes, 1,045 mm in Z direction), the FP 4000 is a machine which might have been tailored for almost any industry, e.g. tool and mould manufacturing or job order production, especially given the company’s position at the forefront of universality and flexibility.

The precision demanded by many customers, even in the µm range, is achieved with absolutely encoded direct measuring systems, high-resolution rotary encoders and YRT bearings with integrated measuring system. The proven 5-axis kinematics in the tool in X, Y, and C, two axes in the workpiece in Z and B, furthermore, combine precision with dynamics.

Potential for process optimisation

The significant advantage provided by 5-axis machining enabling complete machining in a single setup can only be realised with a coherent overall concept. The power provided, for example, must be right and be available at any spatial angle.

It means placing the emphasis in investment on productivity, cutting capacity and availability in order to achieve benefits in the mid- and long-term. With the features presented at INTEC, such as the Power Cutting Universal PCU 63 swivel head, 44kW spindle power, 10,000rpm speed range and 242Nm maximum torque, HELLER is setting the standards in these respects.

Beyond doubt, 5-axis machining holds great potential for process optimisation. When the milling cutter is tilted, for instance, using tools with a reduced throat depth becomes possible. As a result, machining times are shorter and the surface finish is improved due to the reduced susceptibility to vibration. Peripheral milling or face milling of sculptured surfaces provide further potential. Instead of highly dynamic milling at low feed rates, HELLER is offering machining at high feed rates with model FP 4000. An approach that has been paying off already for many users of the F series.

Germany

Germany