HELLER 2013: standing firm in unstable times

In 2013, HELLER placed a strong emphasis on the further development and refinement of its products.

- Completion of existing machine series

- Expansion of solution competence to additional applications

- CBC technology receives environmental award and generates orders

- Strengthening of our international presence

- Expansion of international personnel development and staffing levels

Despite all this, business of the German machine tool industry, including HELLER, was affected by the economic slowdown. Order intake at

413.5 million EUR saw a stronger-than-expected decline compared to last year's above-average volume. As expected, 2013 turnover at 532.7 million EUR was 59.7 million EUR below the record result of 2012. But 2013 turnover is the second highest in the history of the HELLER Group, still beating the average of the past 10 years by 30%. In view of the current economic climate, the company's unchanged overall performance of 496.7 million EUR represents an impressive and far above-average result.

Order intake: strong increase in the second half-year.

The decline in order intake is largely due to subdued order intake from project business with the automotive industry that experienced a significant decrease, particularly during the first six months. In the second half-year, the tide turned: order intake increased significantly, even being considerably above the prorated annual plan – however, without being able to fully compensate the shortfall from the first six months. The positive development clearly continues in 2014. Despite a declining market, the company has been able to expand single-machine business, benefiting from the expansion of the product portfolio.

Origin of orders: Europe is back.

Due to weaker project business, which in previous years had been supported by orders from Asia and the US, major shares in order volume have shifted back to Europe. 66% of all orders came from Germany and the rest of Europe (previous year: 46%), whilst the share of new orders from Asia declined to 19% last year (2012: 34%) and that of North and South America to 15% (2012: 20%).

Order trend 2014: positive development continues

Three months into 2014 HELLER records a positive development in order intake. At 187 million EUR, order intake is 120% above the previous year. As a result, orders received in the first quarter compensate for the disappointing development in 2013. So far, the positive trend has continued into the second quarter. For the overall year the company expects an order volume of more than 500 million EUR.

Healthy profit situation, sound equity ratio.

Investments into the future, e.g. the start-up of the new assembly plant in China and additional development efforts are reasons for satisfactory revenue though below that achieved in 2012. A particularly positive development: despite the decline in turnover equity capital has grown again to now

106.4 million EUR. This increases the equity ratio to 34% from 31.2% in 2012.

In addition, HELLER is now debt free. This has been achieved as a result of consistent accounts receivable management amongst other reasons. It also provides leeway for offering our customers numerous attractive financing solutions an increasingly number is asking for in their investment considerations.

Record development expenditure: expansion of regional business

The 2013 investment volume stabilised at a high level being significantly in excess of 16 million EUR. Investments focused on the assembly plant in China, machines and other equipment and modernisation of operating and business facilities.

In response to the growing market in Eastern Europe we are investing to increase customer proximity, e.g. with the expansion of our sales and service activities at the HELLER location in Yekaterinburg/Russia. Poor economic climate in Russia – partly due to the weak exchange rate – that became evident at the end of last year has further declined since the beginning of the year. Despite the current crisis, which makes planning of activities a challenging task, we consider the strengthening of our presence in the Russian market an investment into the future.

Another priority was development expenditure. Last year, the company spent at total of 14.1 million EUR in this area – 10% up on 2012. The focus was on the diversification of the product range, enabling the company to better serve its existing customers and expand business into new target groups, attracted by the traditional strengths of HELLER, including customers from outside the company's traditional clientele from the automotive industry. At the same time, we continued working on the expansion and intensification of our regional business.

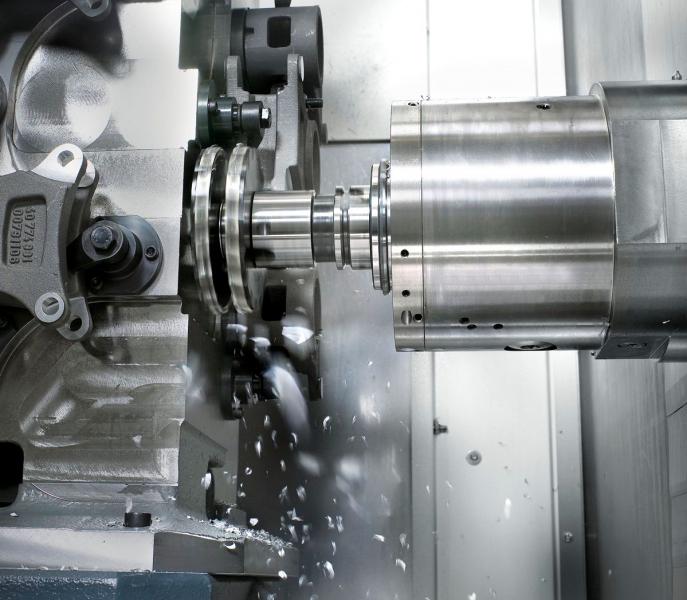

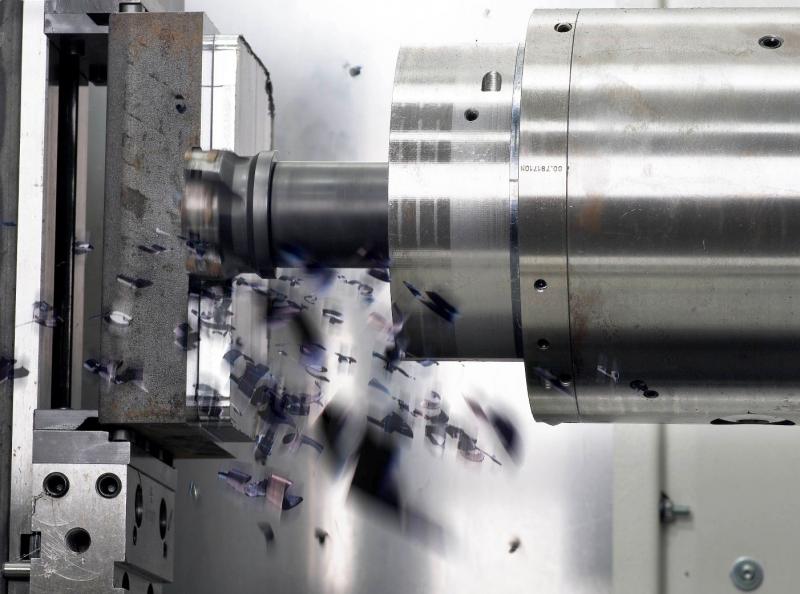

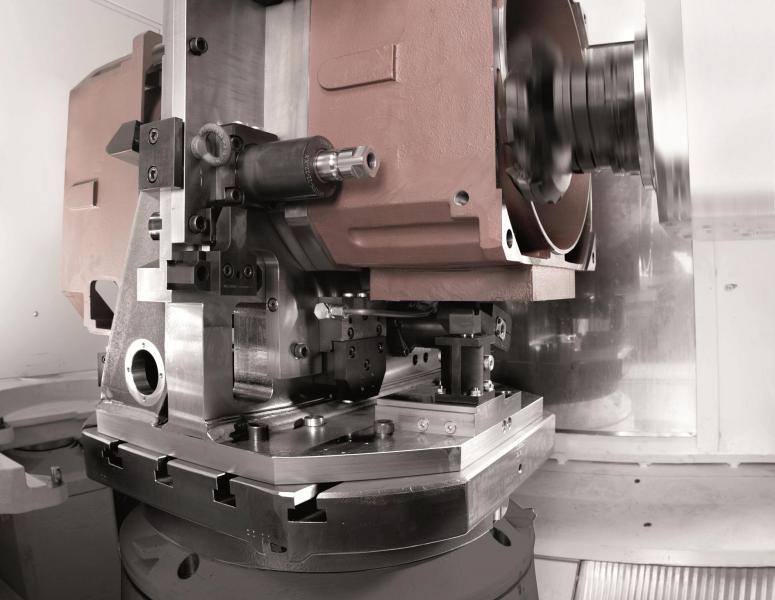

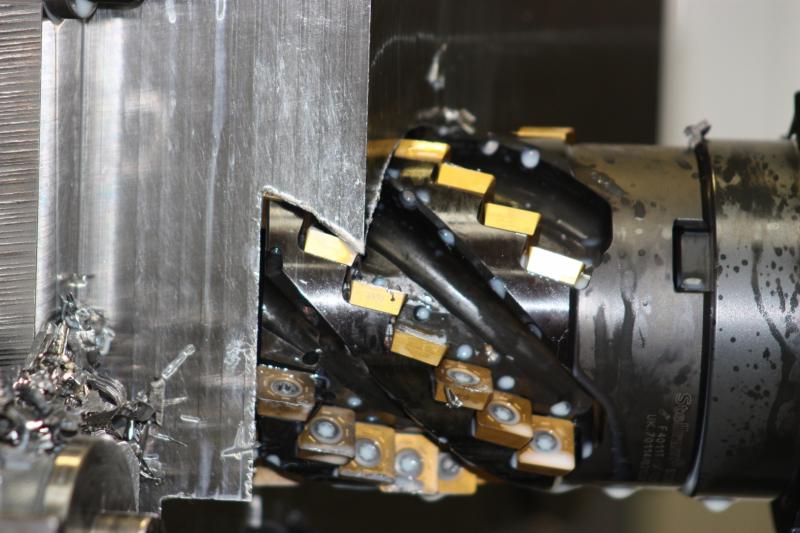

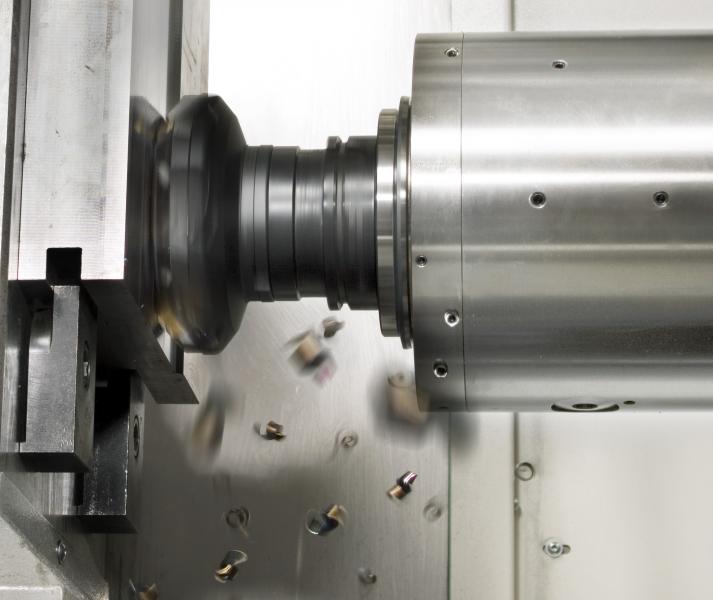

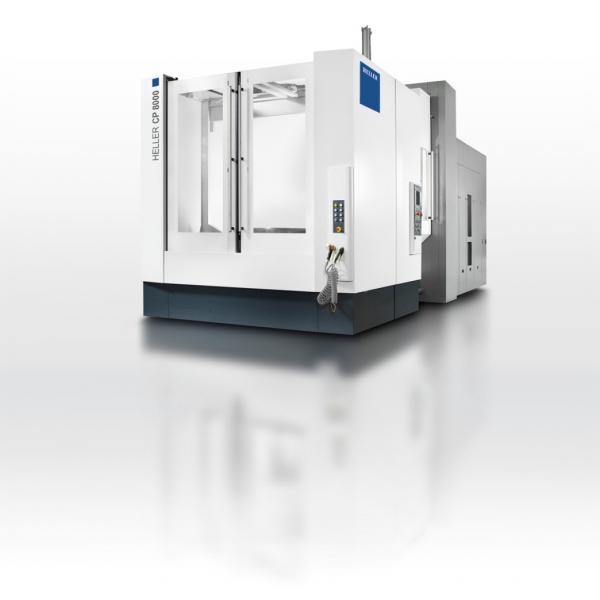

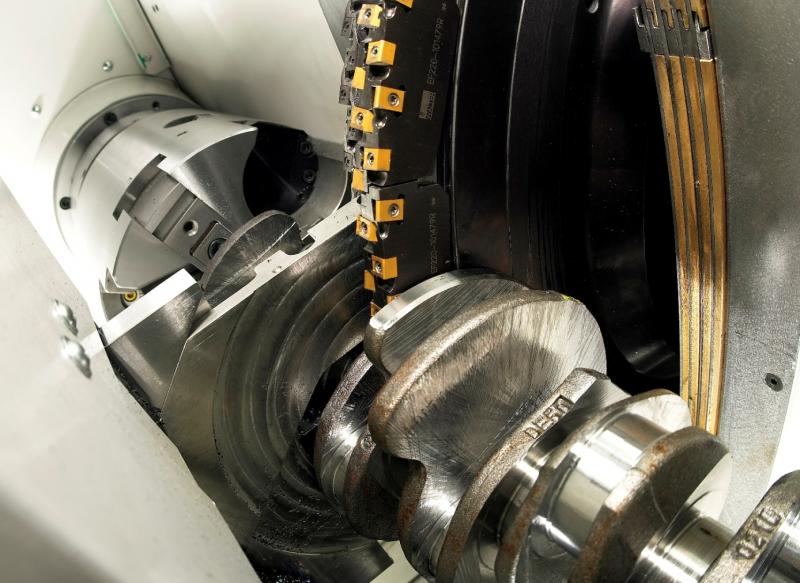

Three new developments and numerous product enhancements result in a completely revamped and expanded product portfolio for 4-axis and 5-axis machining and combined milling/turning, especially in terms of large-part machining. Another addition is a completely new developed external milling machine for the machining of small light-duty crankshafts to round off the lower end of the product range in terms of external and internal milling processes.

In terms of its turnkey competence for crankcase manufacturing systems, HELLER is offering systems for the coating of cylinder bores on the basis of twin-wire arc spraying technology already successfully introduced in the market. Under the name HELLER CBC (CylinderBoreCoating), HELLER it expands the process chain in crankcase manufacturing. First systems are already in operation for high-volume production in Germany and Japan. At the production location in Nürtingen, the HELLER CBC TechnologyCenter is operating a flexible system showing the current status of development that can also be used directly for customer projects.

A look back at the past and a journey into the future: 2014 – HELLER's anniversary year.

There is a lot to celebrate for HELLER in 2014: in July the parent company in Nürtingen will be celebrating its 120 year anniversary. The company continues to operate as an independent, family-owned business. At the same time, the HELLER branches in Redditch/UK and Sorocaba/Brazil are celebrating 40 productive years as part of the global HELLER production network.

For 120 years, spanning three generations, HELLER has been a successful owner-managed enterprise: independent and family-owned. Continuity in terms of management and on shareholder level is and will remain part of our policy. In mid-2013, the great-grandson of the company founder, thus representing the fourth generation of the family, became shareholder of the company in preparation of the generation change.

Berndt Heller continues to act as Chairman of the Supervisory Board. His son-in-law, Christian Pfleiderer, has been active in the leadership of the company since 2013 and is now responsible for global service business. This success story is something HELLER can rightly feel proud of. However, it also requires us to invest thought in the perspectives of the globally operating group today.

We are convinced that continuity on shareholder level, long years of experience in leadership, shared values and a clear orientation provide the ideal basis to be well set up for meeting the challenges of the future – far beyond the year 2020. All customers and prospective buyers of HELLER will benefit from these activities in the same measure. With enhanced and even more precisely customised products and solutions. With specially targeted consulting. With further enhanced tailor-made service solutions – wherever the partner is located. Guaranteeing 100 percent “Made by HELLER”.

Employees worldwide: equally qualified and committed.

More positive news: in 2013, the HELLER Group again achieved an increase in staff numbers. In detail it means that at the end of year, HELLER employed 2,436 people, including 1,840 staff in Germany.

The strongest growth in personnel was noted at the Chinese locations. The development triggered by the new foundation of the production facilities in Changzhou in autumn 2013 accounts for the significance of the Chinese market.

Independent of the location, the high quality of the HELLER products and services is backed by dedicated and qualified staff everywhere. That is why we remain committed to not only maintain the high quality level but to globally promote and enhance it through special measures and qualification programmes. Mastering this challenge is one of the most important tasks of the HELLER organisation as a whole.

Training and personnel development at HELLER are key to tomorrow's success. That is why the company is proud that, throughout the world, the name HELLER has for a long time been synonymous with excellent products and services as well as for outstanding, renowned and sophisticated vocational education and advanced training – at all production locations.

This claim is backed by convincing evidence: the quality of our training not only manifests itself in excellent qualifications and results of HELLER graduates but also in numerous co-operations with other companies. For some time now, HELLER has been training their young talent during the first 1.5 years. Another project in this context is the MAT2 Program currently implemented in the US. In the course of this scheme the proven German educational standards are implemented at our foreign subsidiary with the support of the State of Michigan.

For many years, exchange programmes, some starting at completion of the vocational education, have formed a cornerstone, aiming to achieve even more successful co-operation of all HELLER locations in the future. One example is the participation of our trainees in the European exchange programme called “Leonardo da Vinci” in co-operation with the HELLER branch in the UK. Our American trainees also visit Nürtingen every year for traineeships of several weeks.

To ensure that our products and services are of comparable excellent quality worldwide, we have additionally implemented an international personnel development programme, ensuring comparable knowledge and skill levels following uniform standards and built on identical contents and regular training. The scheme is supported by specific HELLER knowledge management tools and databases and is being developed further into new future-oriented dimensions.

These measures will help to ensure that our customers around the globe will be able to benefit from highly knowledgeable and skilled HELLER staff.

Following the continual development of HELLER health management and its constant expansion in the last 4 years, the current programme now covers a wide spectrum. Continuous programmes and special campaigns in the areas of nutrition, exercise and stress prevention are available to all staff members. The enhancement of our people's well-being and health is in the foreground of all activities, promoting a positive attitude towards everyday work life.

Future perspective: high-quality machines and state-of-the-art solution competence supporting the success of our customers.

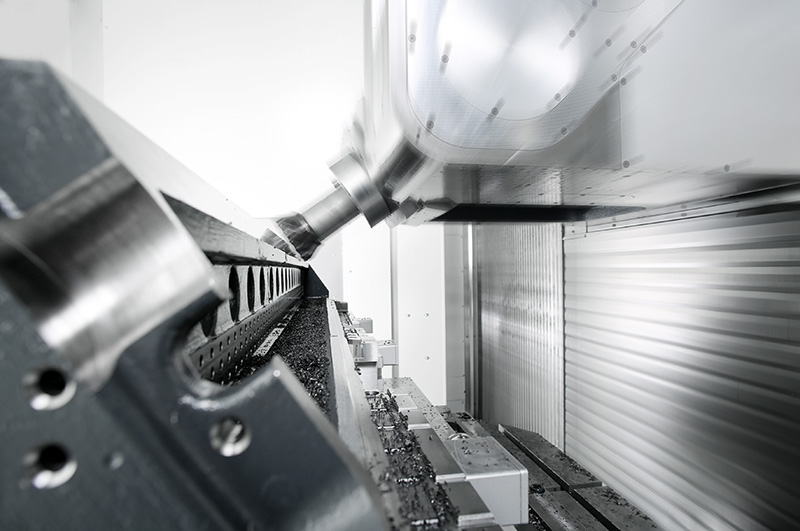

The investment in a new machining centre has to pay off. To make production future-proof, our customers need reliability, precision and high productivity. In response we provide a combination of high-quality mechanical engineering and state-of-the-art solution competence.

HELLER solution competence results from the product itself plus our process-specific know-how. Through our solution competence we are strengthening the unique selling points of the product. We offer customers the added value and security to operate our machines with a high level of reliability and productivity. This is true for complete solutions from stand-alone machines through to turnkey manufacturing systems worth 150 million EUR. From new machines and full-service agreements through to retrofits. Always geared towards the requirements of our customers.

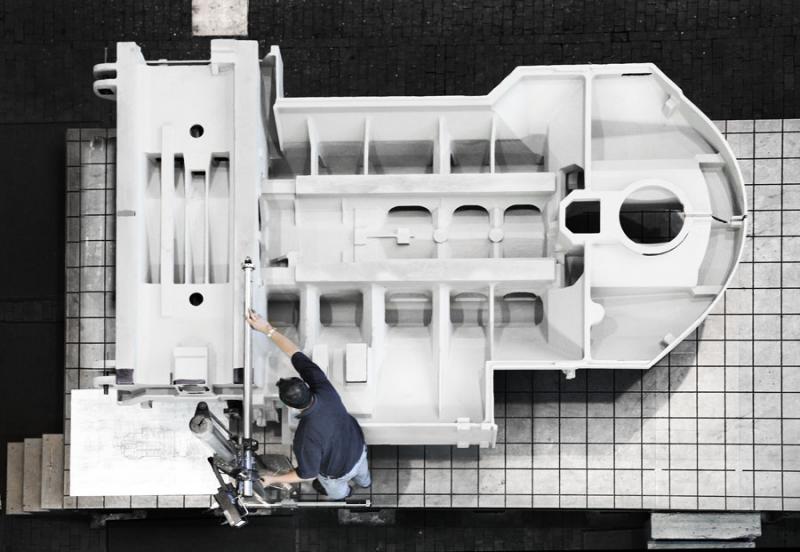

Our high-quality machines need to meet today's demands of modern production. That is why HELLER products are based on a modular system. Well before the introduction of series production of machining centres in 1960s, HELLER already focused on the development of a modular product range. The BEA model range was in the vanguard of this development. Until today, we aim to offer our customers the greatest possible range of flexibly configurable products. That is why we build on the concept of optimising existing base machining centres and modules with optional and customised extensions tailored to the specific requirements of each user.

For example: special spindle units, tool magazines or workpiece management systems. This enables us to supply HELLER solutions perfectly tailored to each customer's production requirements, in other words, a tailor-made 'off the peg' solution. This way we are combining customised solutions with the cost benefits of series production.

Our path into the future: with new ideas and concepts built on proven know-how

On 1 July 2012, Dr Christian Lang took over responsibility for regional sales in Europe followed by management responsibility for regional business in Germany on 1 February 2013. In addition to the leadership of the European sales organisation and close co-operation in the further development of our customer-oriented range of 4-axis, 5-axis and mill/turning centres, his tasks included optimisation and intensification of sales activities regarding stand-alone machines. For personal reasons Dr Lang retired from is executive post on 1 May 2014.

With the conceptual work initiated by Dr Lang regarding the development of HELLER's regional sales activities we are well set up for the future. Besides our successful activities in our traditional field of automotive business, we will continue on this path taking a focused and targeted approach.

Responsibility for the activities started will be taken over by Christian Pfleiderer who is currently working on the successful restructuring of our worldwide service activities towards global market requirements.

We are convinced that our existing product and service portfolio will enable us to continue to be successful in the market as a globally oriented and family-owned business. Feedback we receive from our customers every day clearly confirms this.

Germany

Germany