They're genuine classics among numeric contouring controls: HEIDENHAIN controls of the TNC 150 series consisting of the TNC 150, TNC 151 and TNC 155 controls have been reliably providing their services on milling machines across the world for more than 30 years. HEIDENHAIN has ensured the complete supply of spare parts and replacement devices throughout this period, but technical progress has now become apparent with parts supply for TNC 150 controls—parts required for repairs can now no longer be produced. This production has partly ceased to be economic, but is also technically no longer feasible. Developments are particularly striking in the electronics sector, meaning that assemblies and their associated technology, sometimes over 30 years old, are simply no longer available.

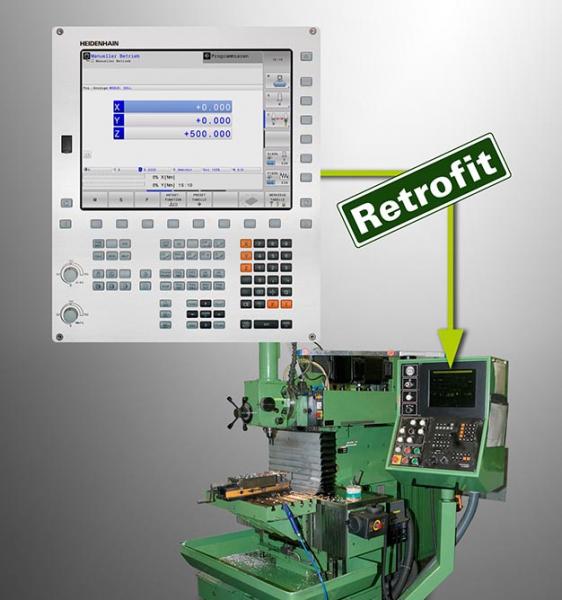

Despite this, TNC 150, TNC 151 and TNC 155 users can of course still rely on HEIDENHAIN, even after 30 years, to provide solutions when servicing is needed—machines equipped with the control classics can be upgraded to the latest controls. Such modernizations are particularly advantageous with machines having large traverse ranges and mechanically robust constructions, and customers specify the latest control model for upgrading purposes according to their machine and desired extent of modernization. The TNC 128 or TNC 320 are available for simple 3-axis machines, whereas upgrading to the state-of-the-art TNC 640 control is recommended for machines that are more complex.

The result is a sustainable modernization of machines and production processes, achieving production with greater precision and efficiency. The new HEIDENHAIN controls feature modern hardware with faster processors, significantly larger memories for NC programs and modern, rapid graphic simulation. NC programs are imported via USB stick as standard, and connecting to the company network via Ethernet is just as possible. 2-D drawings can be loaded directly on the control with the DXF import option, and contours or positions for boring and drilling operations are simply clicked on, thereby saving time and avoiding errors during the importing process. Also decisive for many customers is the full upward compatibility of TNC controls—thanks to this, operators can largely continue to use the old NC programs on a control from the TNC 150 range on modern controls. Users rapidly familiarize themselves with the new control thanks to the intelligent user interface, and only new cycles need to be learned, if used.

A special bonus during the 2015 start phase: all upgrading customers show send their TNC 150, TNC 151 or TNC 155 controls back to HEIDENHAIN receive a voucher for an NC programming training at the HEIDENHAIN headquarters in Traunreut. Participants rapidly get to know the new control functions and options, enabling them to put these to good use for everyday production processes. Work on the upgraded machines becomes more efficient and more productive.

Germany

Germany