GIB

Products

GIB Dresden mbH

CAM software

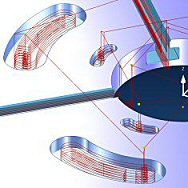

GIBcam-5AX

GIBcam-5AX assists you by reliable 3D programming-strategies to generating NC data for 5-axis simultaneous milling. Combine GIBcam 5-axis CAD/CAM software with the use of highly dynamic multi-axis milling machines to your economic advantage.

Be flexible with GIBcam! Focus on more than 5-axis milling, focus on GIBcam 5-axis simultaneous milling!

Do you want to produce undercuts, deep cavities or spatially curved profiles on a 5-axis machine to create complex forms quickly and inexpensively, for example tire tread patterns, seal lip shapes, forging dies and much more?

Sophisticated geometry data, such as deep cavities, high and steep walls and undercuts, including minimizing long cantilevered tools and multi-sided machining, can be programmed in a well-conceived simple and reliable approach with the established CAM software GIBcam.

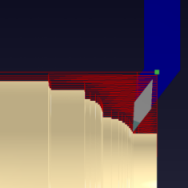

GIBcam-25AX

|

CAM software

GIB Dresden mbH

CAM software

Milling programming the easy way - the complete processing for a wide range of milling tasks can now be programmed with a few clicks of everyone. Often there are potential for savings.

These days a construction design is made in 3D on the computer. Nevertheless, always you come again into the situation that the shop floor requires a design drawing. It does not matter in which part of engineering you look. This may be carried out on the same way into fixture construction, tool making, or vehicle construction, e.g. But it is out of date.

With GIBcam-25AX you get a tool at hand to program all milling and drilling applications inexpensively and safely. NC programs are created based on shape contour, feature and contour curve data. Also you can carry out all simple 3D free-form geometry programming tasks.

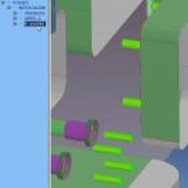

GIBcam-3AX

|

CAM software

GIB Dresden mbH

CAM software

For the CNC cutting any, of simple to highly complex components provides GIBcam a complete "tool box" with variable strategies ready. Whether in aluminum, ceramic, plastic or steel, for example, the technology of processing can be optimally designed with CAD / CAM software GIBcam.

GIBcam has everything you need for 3D programming: strategies for roughing, Nachschruppen, finishing and editing of residual material. And when times only curve contours are to be processed - this is not a problem with the strategies for contours and pockets in the area of 2D or 2.5D milling. Of course, connected with visual tool and tool holder library, the management of interface data, the automatic determination of overhangs and the support of special tool shapes

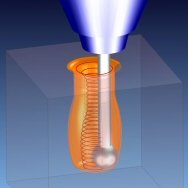

GIBcam-DRILL

|

CAM software

GIB Dresden mbH

CAM software

Professional programming with the 3D CAM system GIBcam -DRILL for drilling , deep hole drilling and milling on feature - based

Modern, professional and easy to program. Wherever is drilled and milled - whether mold inserts , slide , ejector plates - whether as a service provider , plastics processors ...

User experiences speak for themselves ; a reduction of the time required for calculation and programming of 75% for both is possible.

GIBcam is the CAM programming system for creating NC programs for the drilling operation on the basis of CAD data. Whether it is hired drilling , for example, in woodwind instruments to is the pre-processing of steel ingots or crafting of hydraulic components - always GIBcam can help to increase the efficiency and safety of production. Just like for example when plastic injection mold - where GIBcam with the challenge of many cooling circuit or ejector is easily mastered.

GIBcam-TURN

|

CAM software

GIB Dresden mbH

CAM software

GIBcam-TURN is the complete solution for the 2-axis turning to program 2-axis CNC turning centers or lathes. The software seamlessly integrates the GIBcam operating concept and complements the GIBcam product portfolio by turning technology. Therefore, it is characterized by a very low learning curve in relation to the operation.

With GIBcam TURN all tasks can be completed around the 2D rotation programming. Output data for programming can import CAD interfaces, including DXF, DWG, IGES and STEP are provided. Or the contour information is entered using the 2D curve design directly in GIBcam TURN.