Hi all. After much research and a little sweet talking to my finance manager I picked up a G0704 last week. I have started the tear-down process and plan to model the mill in Inventor to start planning my conversion.

A little background... I work for a fab/machine shop as a CAD designer, we have many manual machines but no CNC's other than the plasma table. My main hobby interest for the last 20 years has been R/C. I picked up a 7x lathe around a year ago and was bitten pretty bad by the machining bug. So at this point machining is my main interest with R/C morphing into a medium to produce parts for. This will be a slow build as garage time is limited to around 6 hours a week and I'm very picky about the fit an finish of my parts. I have not ordered any tooling yet but I think that works out in my favor because I won't be rushing to make any chips. I enjoy forum surfing and build threads. I also plan on learning, sharing and contributing to this forum; both in this thread and in others.

Just incase no one has seen a G0704 on a pallet

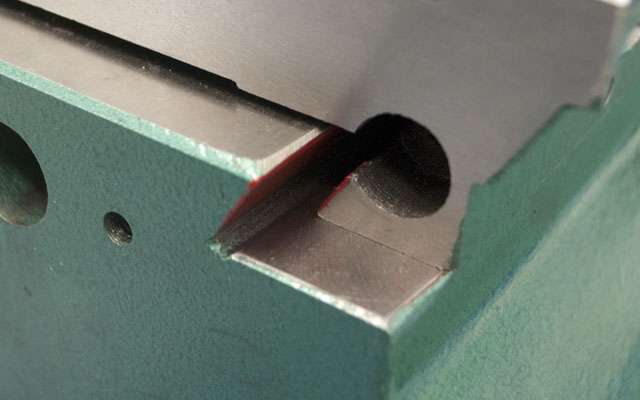

Got to love China QC

Thread: rob_b's G0704

Results 1 to 20 of 62

-

04-27-2012, 03:51 PM #1

rob_b's G0704

-

04-27-2012, 04:07 PM #2

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Welcome to the club rob!

Wow, they cbored that one half way to china.

Hopefully that's your only real fault with the mill, did yours come with the 3-bolt head mod done already?

That makes 2 of the mods on my site they've added since the beginning, wonder what's next? Belt drive?

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

04-27-2012, 04:10 PM #3

Yes, it has the 3 bolt mod. Build date stamped on the head is 3/12.

-

04-27-2012, 04:19 PM #4

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Boy, they aren't wasting any time shipping these out now, hope this isn't a sign they are cutting corners again.

Best of luck, Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

04-27-2012, 05:01 PM #5

I have to agree that they are obviously rushing these out the door. While the botched hole location should ultimately have no effect on the machine operation it does show a general lack of concern towards build quality. Like others have posted there is still sand from casting and many edges have not been de-burred at all. Oh well, tuning these up is half the fun right. :cheers:

-

04-27-2012, 09:18 PM #6

Gold Member

Gold Member

- Join Date

- Aug 2010

- Posts

- 630

-

04-27-2012, 09:35 PM #7

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

http://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

04-27-2012, 10:05 PM #8

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 0

Oh good another new build thread, welcome rob, and when you do get to making chips you'll be able to machine some pretty good 3D parts for your RC hobby and who knows you may even make a few bucks with your new designs too and pay off your finance manager

Thanks for sharing and keep loads of pics flowing.....Eoin

-

04-27-2012, 10:44 PM #9

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 489

Hi Rob. Nice machine you have there. I too started down the machinist road making parts for RC, but left that stuff in the dust since...too expensive, not enough money to buy tooling and other machining stuff

Your going to like that mill, even before CNC'ing it.

Good luck with the build.

Paul

-

04-28-2012, 12:39 AM #10

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 0

meant to add in my last post too jeez I love the truck......

...and yup as you said the missing casting won't affect your ability to adjust and tighten the X axis stock Leadscrew Nut.....and if it's of any significance to you I used these screw points to secure my X axis Ballnut for my conversion too….

Eoin

...and yup as you said the missing casting won't affect your ability to adjust and tighten the X axis stock Leadscrew Nut.....and if it's of any significance to you I used these screw points to secure my X axis Ballnut for my conversion too….

Eoin

-

04-28-2012, 02:01 AM #11

Thanks guys. I have actually been designing, producing and selling R/C products for the last 4 years or so. Made some pretty good money for doing it as side work/hobby. However its gotten to the point that I needed a cnc mill in the garage to elevate myself to the next level. So I am putting it all to the side for now with plans to go back swinging after the conversion is complete. Pretty nice for a work truck isn't it. They take care of me well.

-

04-28-2012, 06:08 PM #12

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 0

Well done Rob on deciding to jump on board.

Good luck with the build.

Im in the middle of my build which is a slow one but hopefully be as right as I can get it.

Ive not got access to another mill and have bought a lot of off the shelf stuff so to speak.

Theres plenty of info on here which has been a great help for me, hoss's plans are great even for just in-depth insight.

Have a browse through my build so far (link below) - nothing rocket science however Ive been getting great comments on the one shot oiler which I recommend having a think about intergrating into your build.

Cheers

John

-

05-06-2012, 09:17 PM #13

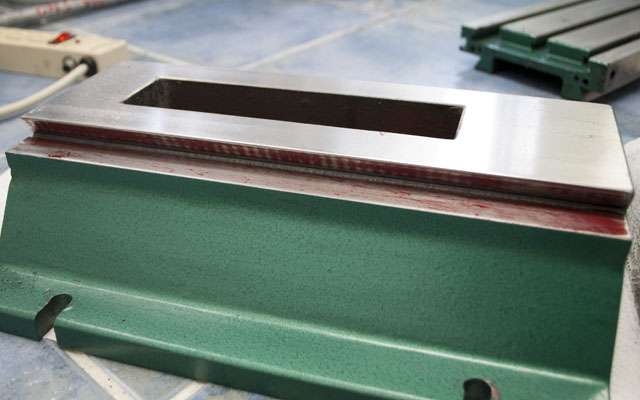

Making a little progress here and finally got the mill completely broken down, also started modeling the various head parts to plan for the belt drive. Before I ever ran my 7x lathe I lapped all of the sliding surfaces and was very pleased with the results. So I started the same for the mill. I picked up a 12x18 surface plate from Enco for $41 shipped

and started with the saddle. The Y dovetails would not sit flat and had a .002" rock across two of the corners. I'm sure scraping would be the proper fix for this but I taped a sheet of 600 grit to the plate and leveled it up in just a few minutes. I couldn't get my phone to catch the glare just right but material was only taken off of the two high corners.

and started with the saddle. The Y dovetails would not sit flat and had a .002" rock across two of the corners. I'm sure scraping would be the proper fix for this but I taped a sheet of 600 grit to the plate and leveled it up in just a few minutes. I couldn't get my phone to catch the glare just right but material was only taken off of the two high corners.

Next up was the Y gib. The back side of it was nice and flat but the sliding surface was in horrible shape. For it I used 400 grit on the plate and eventually got it mostly flat. Then I assembled the saddle and the base to start lapping. When I pulled it apart and cleaned everything up I didn't like what I saw, grooving in the saddle and gib. Looking at the base dovetails closer it looks like a mini mountain range. There is basically 2-3 points of contact on each of the dovetails.

Kinda lost on what to do next, seems like the only options are to scrape the base or live with it. Am I being to picky here?

-

05-06-2012, 10:16 PM #14

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 0

I know this isn't the answer you're looking for....but it really boils down to the tolerances you intend to machine to......as the people who just go about their business and post their progress and some may think “gosh is that really necessary?”…..well the guy’s who put in the time are the guy’s who can achieve the higher tolerances……Eoin

-

05-06-2012, 10:21 PM #15

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 419

I bought my mill within a week or two of yours and I am 99% sure that my dovetails were ground. I'm away from my mill so I cant take a closer look but my surfaces are definitely different from yours.

Perhaps they forgot to grind your ways when they botched the mounting hole?

The bottom side of the dovetail should also be ground, they leave machining marks but if you look at the high spots you should see a ground surface finish. It is hard to get in a photo but there is a close up here: http://www.cncfusion.com/images/G0704/Base-ways.JPG

Scraping the base dovetails would be a pretty extreme job, you need to watch alignment very carefully.

On the plus side, as long as your dovetail is flat and parallel to the other dovetail it isn't nearly as bad as it could be (the saddle dovetails are probably concave and at the wrong angles).

It might be worth just putting a very small amount of (non-embedding) lapping compound on only the dovetail surfaces (+ gib) and breaking them into eachother. If you do one side at a time it should help keep things aligned. Just got to make sure you don't twist the saddle as you move it back and forth.

-

05-06-2012, 10:43 PM #16

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 839

Have you got a real good long file? They can work really good on getting it flat, plus keeping it straight. A fine cut should be all thats needed, you dont want to take to much. Be sure and use long, complete strokes so it works it down even. The file needs to be longer than the surface or you will get more cut on one end than the other. Using a wood board with a cut to macth the dove tail can help to keep good even pressure on the lenth of the file. Dont make any strokes where the file does not have full contact with the dovetail. EVen if this only allows a few inches of stroke stop when you reach the end of the file (it must have full lenth contact at all times). Plus dont use the file like a saw, only cut in one dirrection while keeping the board against it full lenth to keep even pressure all the way across the cut.

JessGOD Bless, and prayers for all.

-

05-07-2012, 02:02 AM #17

The horizontal surfaces are indeed machined/ground. The base dovetails are the only surfaces that look out of place to me.

On a brighter note I found my new go to beer. Try and say its name 5 times fast, I can't even say it once:cheers:

-

05-07-2012, 02:30 AM #18

Registered

Registered

- Join Date

- May 2008

- Posts

- 11

Measure first!

I have had my machine now for about 6 months and have competed Hoss's CNC conversion. I am getting 1-1.5 mill accuracy and have not had to do any of the stuff you are doing. I would suggest you measure your machine's accuracy out of the box to see what is needed. The old saying is if it's not broken don't fix it.

The main problem I needed to fix was the front to back (y-axis) tram which was about 10 mils. I needed a 3.5 mil shim (feeler gauge) to correct the problem.

-

05-07-2012, 03:43 AM #19

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 419

What do you mean by 1-1.5 mil accuracy though? Boring two holes 8" apart to one thou is incredibly impressive while repeating to 1 thou is a joke.

Measuring positioning error in a machine tool is extremely complicated. Jogging an axis one inch and checking how far it moved with a dial indicator doesn't verify anything.

There are 21 possible errors in a three axis mill and the majority of them are cumulative. You can see the kinds of error that shows up in commercial VMCs here:

http://www.heidenhain.com/de_EN/php/...-0209/file.pdf

http://www.heidenhain.com/de_EN/php/...-0253/file.pdf

Some of the test parts are visibly off by 0.005" just due to thermal drift.

-

05-07-2012, 08:39 PM #20

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 0

Cheers for the link it's an interesting read....

Eoin

Eoin

Similar Threads

-

G0704

By kd4gij in forum Benchtop MachinesReplies: 8Last Post: 07-07-2016, 12:00 AM -

DRO for G0704

By UMR in forum Benchtop MachinesReplies: 4Last Post: 07-06-2016, 04:04 AM -

No Joy with my New G0704

By DogWood in forum Benchtop MachinesReplies: 5Last Post: 07-05-2016, 05:49 PM -

G0704... Yes Another One ;)

By ww_kayak in forum Benchtop MachinesReplies: 24Last Post: 05-27-2013, 03:47 PM -

G0704 or a X-3

By USN in forum Benchtop MachinesReplies: 8Last Post: 05-30-2011, 08:24 AM

Reply With Quote

Reply With Quote