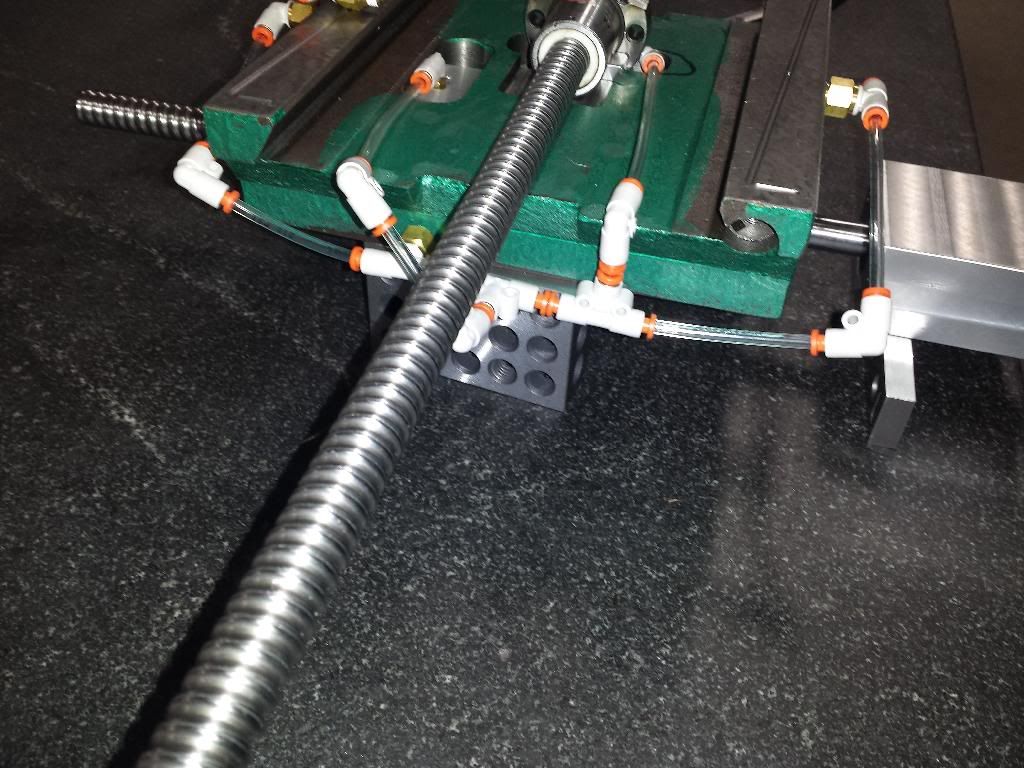

I've just started putting together the G0704 CNC conversion, using the Billy's CNC kit

and the ballscrews from Chai.

The ballscrews I've received were cut specifically for this particular conversion, but...

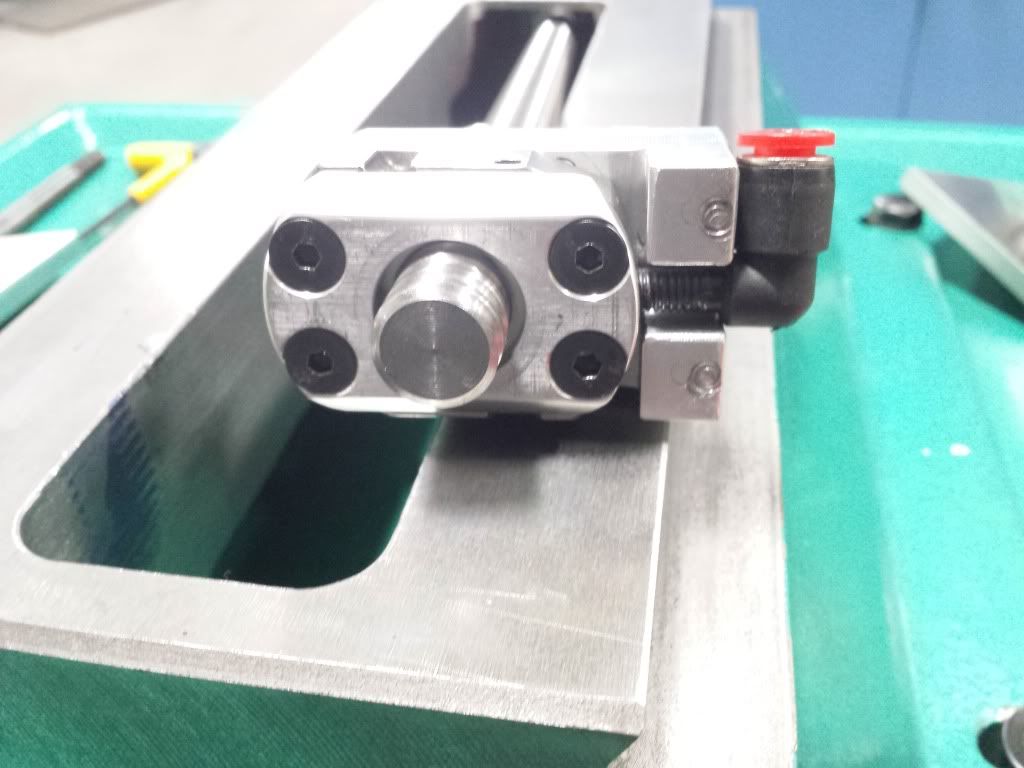

unlike in those template clips I can see on the youtube, my ballnuts all have lubricating

valve added on the side.

The Z gives enough clearance for the ballnut, so it wasn't an issue.

I'm moving over to Y now, and I've just realized that the lubricating valve on the ballnut,

does not have enough clearance to go passed above the two cross bars in the bottom side of the base.

It sticks down deep enough to stuck on them.

Has anyone seen this issue before? How can I get around this?

I guess I can't just not put in the valve, as the hole would let the balls out eventually.

Should I plug it with a short bolt instead? Or can I mill those cross bars down, to make enough room

for the valve to move free above them?

Pic attached for reference.

I'm not sure if this is going to be an issue again, when I get to the X.

tia for your advice,

jarek

Attachment 233386

Results 1 to 20 of 21

-

04-21-2014, 09:35 PM #1

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 16

G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too much.

-

04-21-2014, 10:22 PM #2

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

IIRC most people flip it 180 from the way you have it. The oiling tube comes from above in the saddle. I think.

A lazy man does it twice.

-

04-21-2014, 10:23 PM #3

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

You can drill/tap the mounting holes 22.5 degrees off and slot the center so the fitting will come out the top center as in my new plans.

The X will need a slot in the saddle for the fitting to clear.

I use barbed fittings that take up minimum space.

Hoss

Oh yeah, the balls won't come out of the lube hole.http://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

04-22-2014, 03:37 AM #4

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 16

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

thank you for the help.

I think I will do it just the way you're suggesting.

I just have no machine to do it, now, that I've taken it apart...

Will have to use my press drill to cut this slot.

jarek

-

04-22-2014, 08:59 AM #5

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

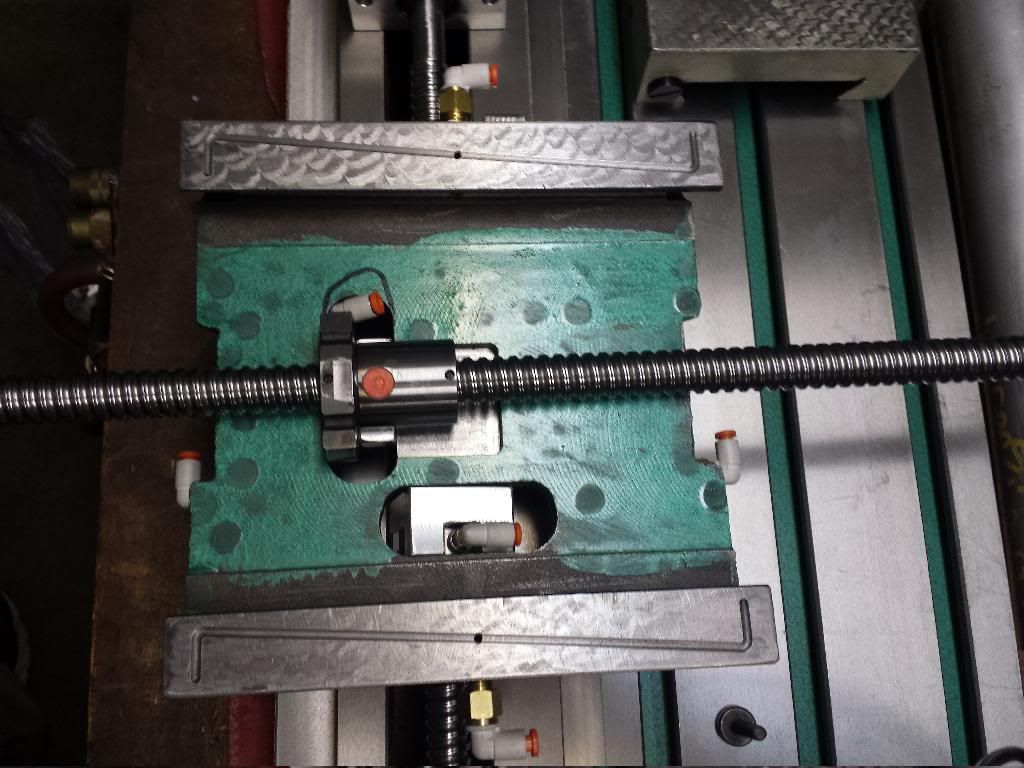

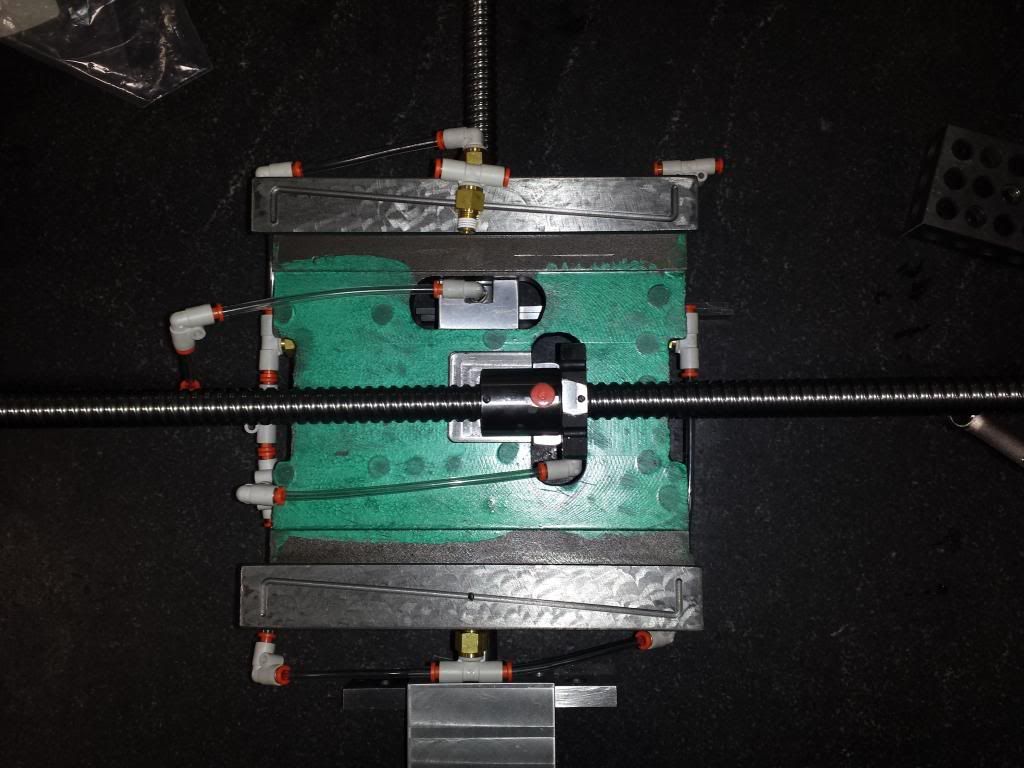

I did like hoss said and rotated the ball nut for the Y axis so the fitting hole was facing up

Then I machined off the the parts that were sticking out the side so it would fit in the pocket

Also made a plate for a physical stop and to prevent traveling to far and losing the BB's from the nut.

On the X I milled the slot on in the saddle a little longer ( maybe .25"?) for the fitting.

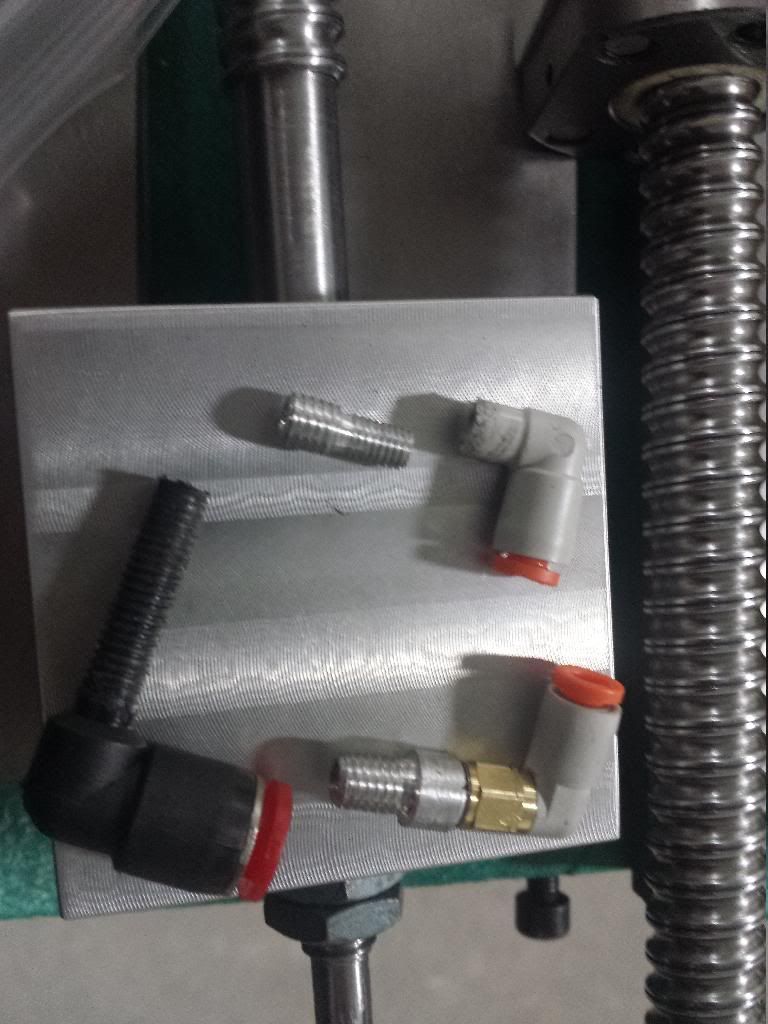

also made adapters for fittings as there's not much out there with an M6 thread and 5/32 (4mm) tube

Hope this helps and I didn't clog up your thread with to many pics

Andrew

-

04-24-2014, 05:57 AM #6

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 16

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

Thanks for the pics and the info, Andrew.

I like the idea of milling those two "Z" in the saddle, for the oil.

I'd love to make those, too, but I'd require another milling machine for this,

while the Grizzly is taken apart...

I'm done the Y now, and it's come out quite neat. I had to mill down the ball nut's sides

as they were sticking out to the sides just a touch too much.

(I hate to confess I'm using my press drill and a cross-vise for this sort of "milling" work...)

The Y seems ok now, and the screw is nicely centered, so I can easily move the saddle with my hand, by turning the screw.

Are those right angle plugs you're using for the oiling valves, something specifically made for this purpose, or you're just using something that fits?

I will have to look for something like them, or something I can make work this way.

thanks again,

jarek

-

04-24-2014, 09:19 AM #7

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

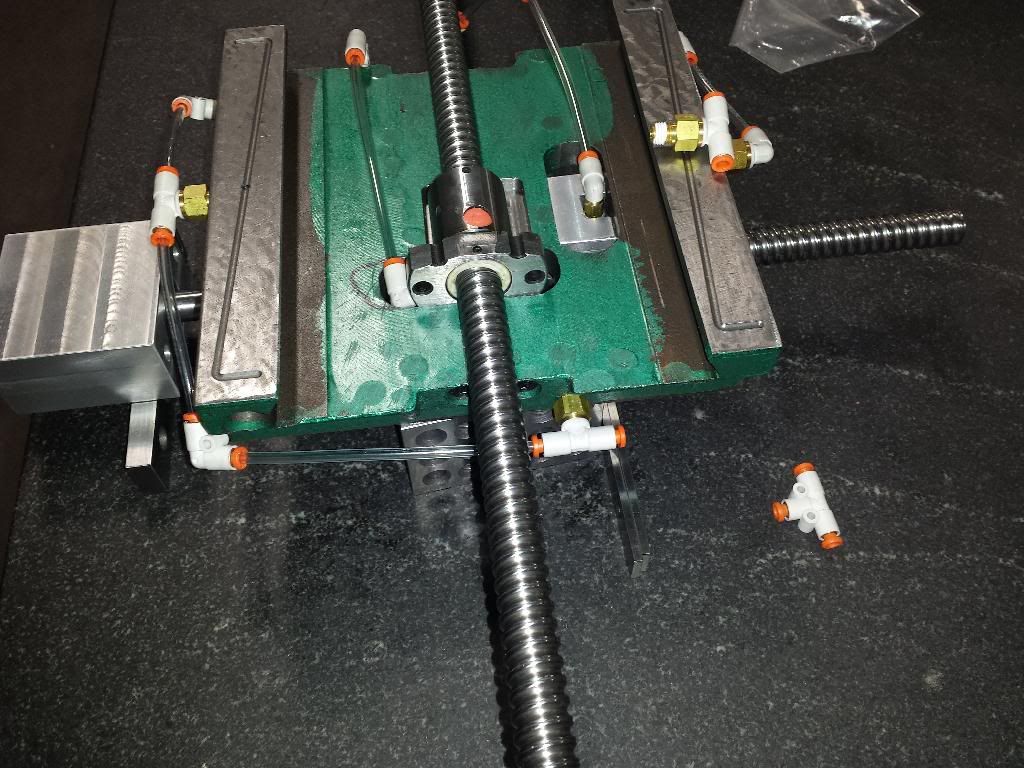

yeah, I took the Z's in the saddle idea from Hoss too! Also on the bottom side of the saddle has them. It's nice having machines at work that I can use to mod this machine!

As for the right angle fittings, I've been getting them from MSC with my works discount. all of them are for oiling the ways and ball nuts. none of them are proportioned or "checked" at the moment. For the y nut I made a 10-32 female to m6 male adapter\spacer with a hole thru. On the X nut I got a 90 degree stem elbow, threaded the stem with a 10-32 tap, cut the stem off right after the bend and made a 10-32 male to m6 male adapter with a hole thru.

Pics of current setup:

-

04-27-2014, 03:55 AM #8

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 16

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

I'm running into more problems, with the X now, and I kind of figure from your pictures it might be quite a common issue, though

I have never read about it.

Using my drill press, and a 3/8 carbide end mill, I've milled about 1/4 in down, to make room for the X ballnut to fit in.

Attachment 234160

My issue is that even if I slide the X ballnut all the way down in the slot, until the ballscrew acutally touches down on the saddle surface(which I believe is wrong...)

there is still not enough clearance above the already shipped milled ballnut. When I slide the top on, it pretty much touches the ballnut's milled top edge.

Attachment 234162

Attachment 234164

Am I doing something wrong? HAs anyone seen such thing before?

Would I now have to mill down a channel in the saddle, to make fit the ballscrew unobstructed, and additionally mill another channel in the bottom of the table,

to make it go safely over the ballnut?

help greatly appreciated.

(forgive my not so pro terminology, wherever sticks out... my day job is in IT, and my background is electronics/telecom...)

thank you all, for the help so far. I start getting an impression this project was too big for me... hopefully I make it, anyway. los of challenges and lots of learning, before I have even got it to work...

jarek

-

04-27-2014, 06:20 AM #9

Member

Member

- Join Date

- May 2008

- Posts

- 1185

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

It is real tight on the nut. Your nut looks to not be ground all the way down. I would grind it more. It is easier if you dump the balls and pull the seals but you can tape it too but you need to watch the heat.

I cut a .020" grove where the screw lays just for a bit of extra room.

It looks like this.

G0704 Pocket RM-16 Ball Screw Photo by arizonavideo | Photobucket

You can go into the nut round part by .020" too with no problem.youtube videos of the G0704 under the name arizonavideo99

-

04-27-2014, 02:49 PM #10

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

What Arizona said.

A lazy man does it twice.

-

04-27-2014, 06:08 PM #11

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 16

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

Thank you.

I will have to find some machine shop local to my me, to help with those cuts.

It's a bit too much for my fiddling around with a drill press...

Especially cutting the 26-1/2 long cut...

It would have to be nice and straight, and even depth, and that I can't achieve with a handheld grinder or something...

What bothers me a bit though, or just makes curious, going over the internet, I don't really see other people have such issues.

It seems all to be straight forward and sooth for them.

Made me wonder if it's because I'm doing something wrong, or perhaps not all those machines are perfectly alike.

I'm really grateful for all your knowledgeable help, everyone, and for the mine of information I can find here.

It would be plain impossible without it.

Till the next weekend...

jarek

-

04-27-2014, 08:24 PM #12

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too...

Well I had to go back and look under my table. I didnt grind the underside of my table but I did mill a shallow slot in the top of the carriage to allow the ballscrew to be lower. Also the top of my ballnut is ground down much farther than yours. Though Chai ground it some, I did quite a bit more (on a bench grinder). I do have an old round column mill here in my garage so an extra cut or two here and there is no issue other than the tear down, do the work, rebuild. I have opened up the slot in the base a considerable amount. In a week or so, after I build the Y axis spacer, I am going to open it up some more!

A lazy man does it twice.

A lazy man does it twice.

-

04-27-2014, 08:33 PM #13

Member

Member

- Join Date

- May 2008

- Posts

- 1185

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

All that could be done with a hand grinder.

The nut is real hard but can be cut with carbide but a grinder or sander works well. Don't get the nut too hot and you will be fine.

Remove all the paint where the ball nut runs on the under side of the table and scrape away any flashing. I don't think it is a good idea to grind the under side of the table if you can do something else but if you have a bump of cast iron in the way you can grind it out of the way.

I had about .030" of clearance when done with a pocket cut to .230" deep and a extra .020" x 3/8" across the the bottom.youtube videos of the G0704 under the name arizonavideo99

-

05-01-2014, 09:22 PM #14

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 16

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

thank you all for your help.

I have now all X, Y, Z put together and looking good.

I've ended up having someone mill a channel 1-3/4in, 3/32in deep, off the bottom of the table

and a similar one, 3/4in wide, for the ballscrew, in the saddle

Everything fits ok now.

but...

As it was to be expected, I've run into new issues now.

Those I believe, I already know how to solve.

The ballscrews I've ordered, came with one coupler each.

The Z was OK, but the X and Y (8mm to 10mm) are too short.

They 1 inch O.D., and only about 30mm long.

And 30mm is roughly the distance between

the motor's shaft end and the ballscrew's end, in both cases, the X and the Y's.

So the couplers are too short to reach both ends at once...

I've already found some on internet, 8mm to 10mm, 32mmO.D. and 40mm long, which should do.

At first I thought, I'd cut the Billy's original spacers short by some half inch, but I'd have to cut over the opening in the tubing,

and that would leave it significantly weaker.

I guess I will have to calm down a bit, and just order (and wait another couple of weeks...) the new, longer couplers...

jarek

-

05-01-2014, 11:37 PM #15

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

jarek, can you take pictures? Billy's spacer? I run the BD Tools kit. You shouldnt need to do anything different. Dont cut anything yet

A lazy man does it twice.

-

05-02-2014, 12:11 AM #16

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 16

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

is that possible the nema 23 steppers come with different length shaft?

The Y spacer assembled looks like this, over an inch space between the stepper's shaft and the end of the ball screw...

Attachment 234740

Attachment 234742

Attachment 234746

Attachment 234748

Attachment 234750

I either have a too small coupler, stepper with a too short shaft, or doing something else wrong.

I've included the pics that would show the actual situation.

thanks,

jarek

-

05-02-2014, 03:31 AM #17

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 116

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

Hi

The couplers you have are way to short for the BD tools mounts. I used these from McMaster-Carr 59985K4 3/8 on the X and Y and the 1/2" on the Z axis by 1 7/8 long. use the set screw type and put two flats on the screw ends and blue Lock-Tite on final assembly. Also make sure you double jam nut the lead screws. You want to keep your preload on the lead screws so you have min back lash.Good Luck.

CH

-

05-02-2014, 04:29 AM #18

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

I used the 1's COM is referring to. The helicals you have arent known to hold up well in these machines. They wind up like a spring and introduce more backlash.

Sorry, I lied. Mine came from MSC.

To all those interested in the couplers I used. I did get them from MSC. IIRC it was a 3 part order consisting of the hub for the stepper, the hub for the ball screw and the acetal insert. The hubs can be purchased in a few shaft diameters but keeping the OD the same for that series.

Hub-Lovejoy MOL32C HUB 3/8 N/KW

PN: 685144 58119

Insert-MOL32

PN: 87693915A lazy man does it twice.

-

06-03-2014, 07:40 AM #19

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 9

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

I'm a little late, I know, but I do see what caused some of your x-axis problems jarekp... If you look at the pics is post #7 and compare them to your pics 1 and 3 in post #8, you'll see that your saddle is almost completely flat through the middle. On most of the G0704 saddles I've seen, there's a .050 or so drop in the middle about an inch from both x-axis ways. Hope this makes sense.

-

06-03-2014, 01:35 PM #20

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 16

Re: G0704 - Y ballnut won't fit in the base, the lubricating valve sticks out too muc

You're not łatę at all, dbranget ...

It makes lots od sense what you're saying. It would also explain why i can't run even a smallest diameter angle from the Y oiler valve out, as the table cuts everything sticking out more than 0.05, when I slide it on the saddle.

I've actually left that part to be solved at the end, and moved on, to building the controller box, limit switches and some other stuff. Sounds like I will have to mill another channel in the table's bottom side, to allow for the tubing to access the oiling valve for the Y.

Thanks for pointing this out.

JJ

Similar Threads

-

Pro/e (Creo) Valve/ Valve seat hard stop mechanism

By skmetal7 in forum Uncategorised CAD DiscussionReplies: 0Last Post: 11-29-2011, 10:18 PM -

Interact 2 speed control valve problems (piloted 5 port 2 soleniod valve)

By ichudov in forum Bridgeport / Hardinge MillsReplies: 0Last Post: 09-06-2010, 05:25 PM -

Tire Valve / Shraeder Valve Dimensions

By jamiedaugherty in forum Mechanical Calculations/Engineering DesignReplies: 19Last Post: 01-22-2010, 04:46 PM -

Preloaded ballnut vs stock ballnut.

By spaceballs_3000 in forum Benchtop MachinesReplies: 12Last Post: 04-24-2008, 07:35 AM

Reply With Quote

Reply With Quote